Gyration type engine maintenance platform

A technology for overhauling platforms and engines, applied in the field of automobiles, can solve problems such as inconvenience in use, and achieve the effects of reducing vibration, facilitating fixed-point inspection, and improving the shock absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

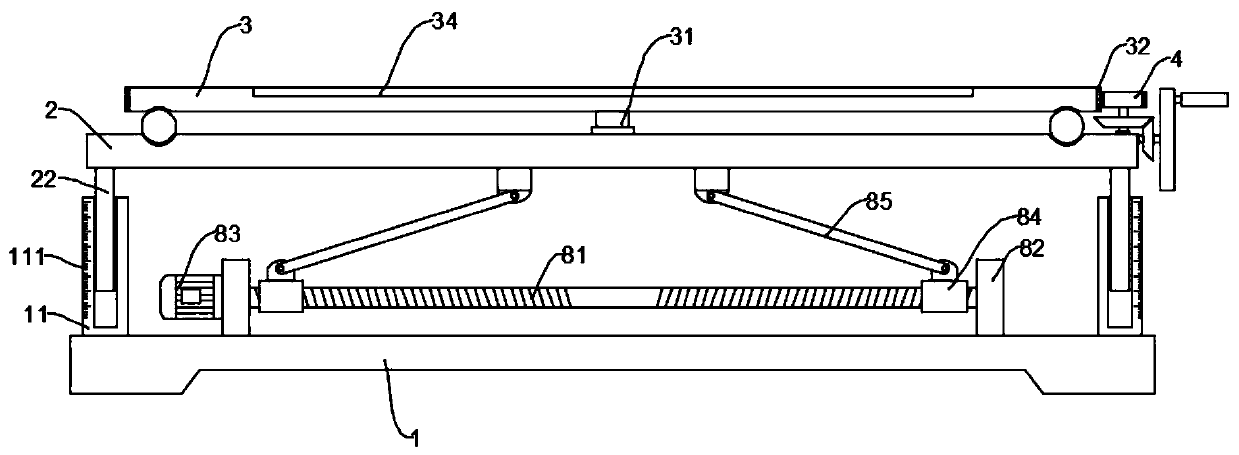

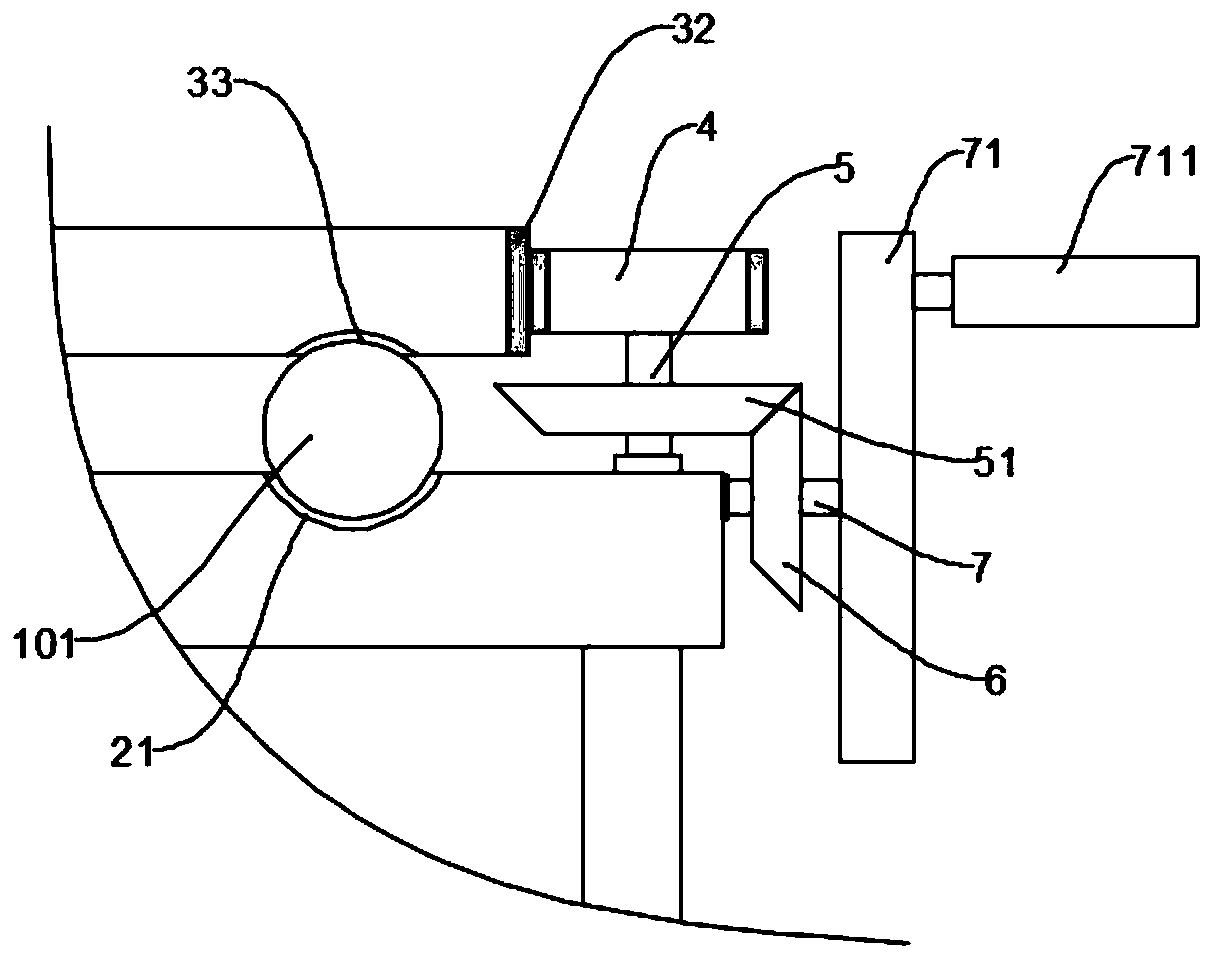

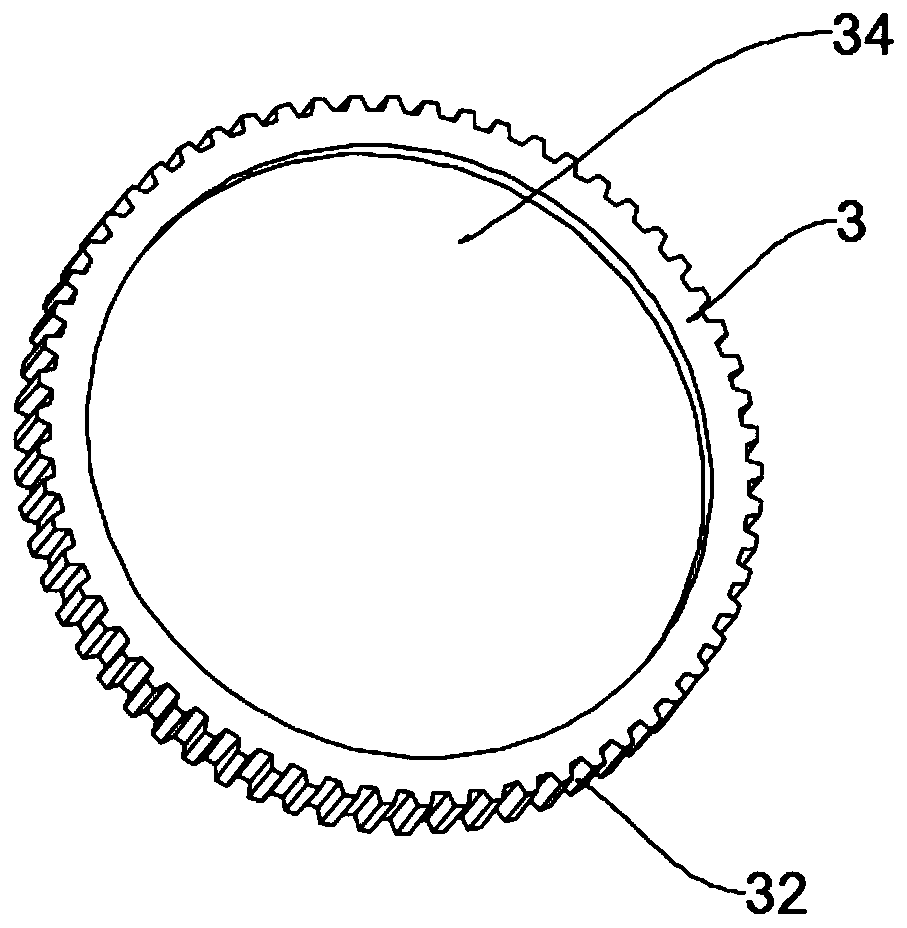

[0024] see Figure 1~3 , in an embodiment of the present invention, a rotary engine inspection platform includes a workbench 3 for placing the engine, a movable seat 2 for supporting the workbench 3, and a base 1 for supporting the movable seat 2; The workbench 3 is connected to the movable seat 2 through the support shaft 31, so that the workbench 3 can be rotated, which is convenient for the staff to carry out fixed-point inspection, and brings convenience to the development of the maintenance work. The workbench 3 is circular and An annular tooth surface 32 is integrally formed on its outer peripheral surface, and the top of the movable seat 2 is rotatably connected with a first rotating shaft 5 at a position corresponding to the edge of the workbench 3, and the top of the first rotating shaft 5 is fixed with a ring meshing with the annular tooth surface 32. Drive gear 4; the drive gear 4 is equipped with a drive mechanism to drive its rotation, the drive mechanism drives t...

Embodiment 2

[0032] see Figure 4 The difference between this embodiment of the present invention and Embodiment 1 is that a shock-absorbing seat 9 is installed on the bottom of the base 1; The arched plate body is fixed on the base 1, and the lower part of the straight plate body is provided with a bottom plate 91 at intervals. A spring 93 is connected between the bottom plate 91 and the straight plate body. The elastic plate 91 Cooperating with the spring 93, it can realize multi-stage shock absorption and improve the shock absorption effect of the shock absorber 9.

[0033] The working principle of the present invention is:

[0034] In the present invention, by setting the rotating workbench 3, it is convenient for the staff to carry out fixed-point inspection, which brings convenience to the deployment of the maintenance work, and the manual drive mechanism is used to drive the driving gear 4, which is beneficial to the staff's control of the workbench 3. The rotation angle is contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com