Bottle falling equipment and bottle falling method for plastic ampoule bottle filling sealing machine

A plastic ampoules, filling and sealing technology, applied in packaging, conveyors, conveyor objects, etc., can solve the problems of unstable subsequent operation, causing accidents, affecting the continuous operation of production lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention provides a plastic ampoule bottle filling and sealing machine bottle dropping equipment and bottle dropping method. In order to make the purpose, technical scheme and effect of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

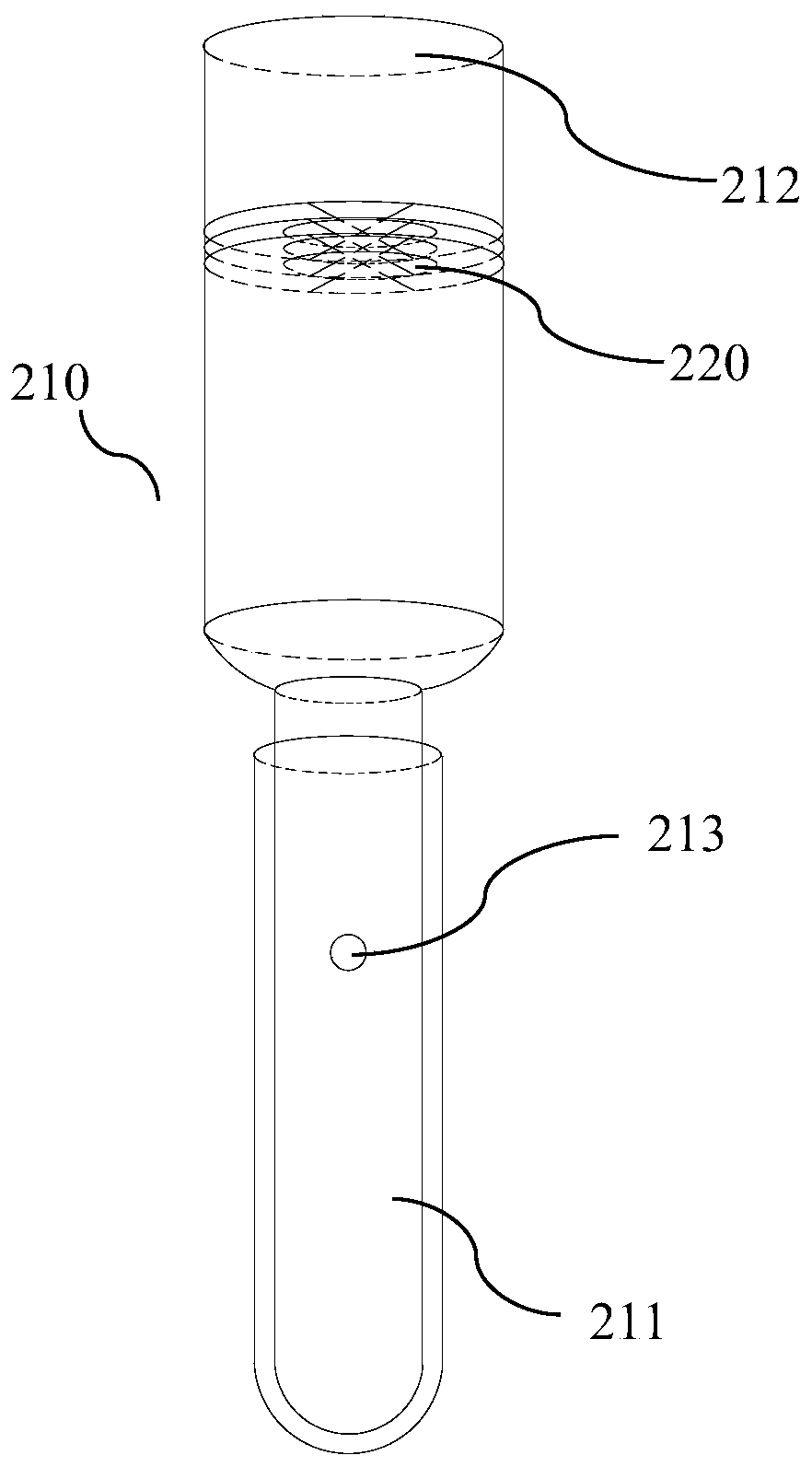

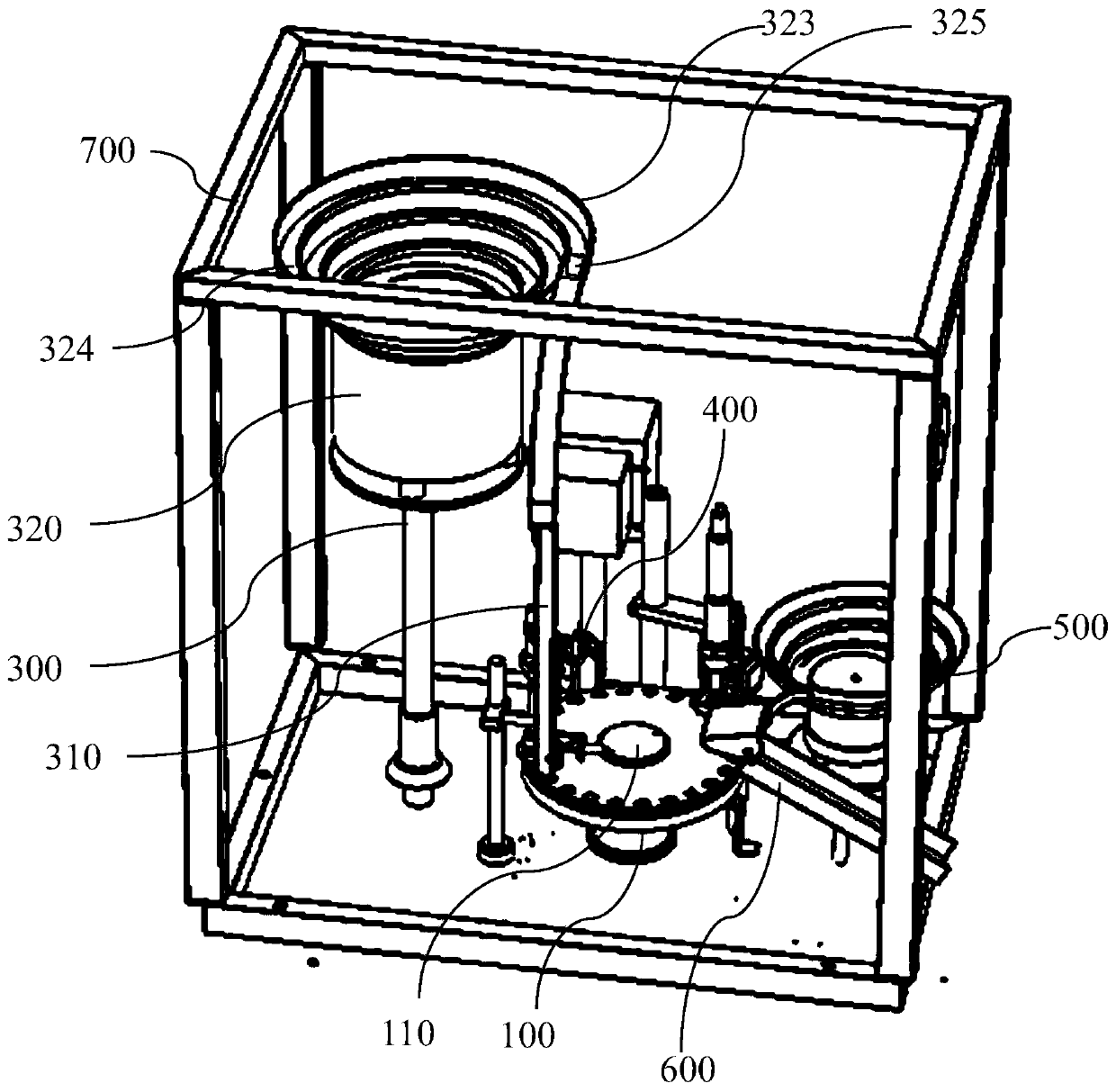

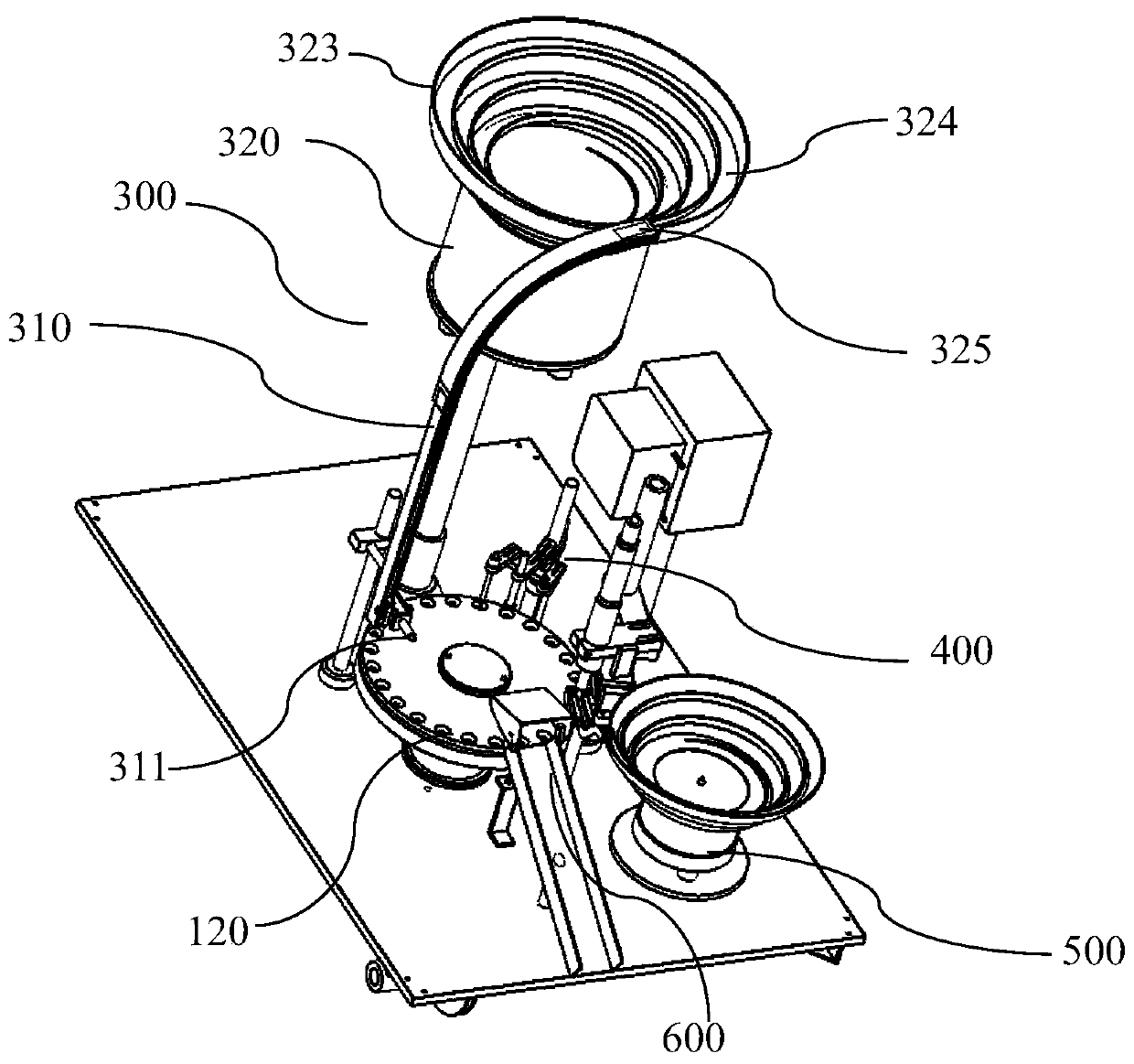

[0048] The plastic ampoule filling and sealing machine bottle dropping equipment of the present invention is applied to a plastic ampoule filling and sealing machine, and the overall structure of the filling and sealing machine is as follows: figure 2 As shown, it includes a turntable 100 rotatable around a central rotating shaft 110. The rotating disk 100 is provided with at least one receiving hole 120 along the circumference, and the center of each receiving...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap