Bead selection machine

A technology of bead selection machine and bead selection device, which is applied to embroidery machines, embroidery machine mechanisms, automatic control embroidery machines, etc. It can solve the problems of mixed embroidery beads, hole diameters that cannot meet the needs of bead embroidery, and affect the use of bead embroidery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

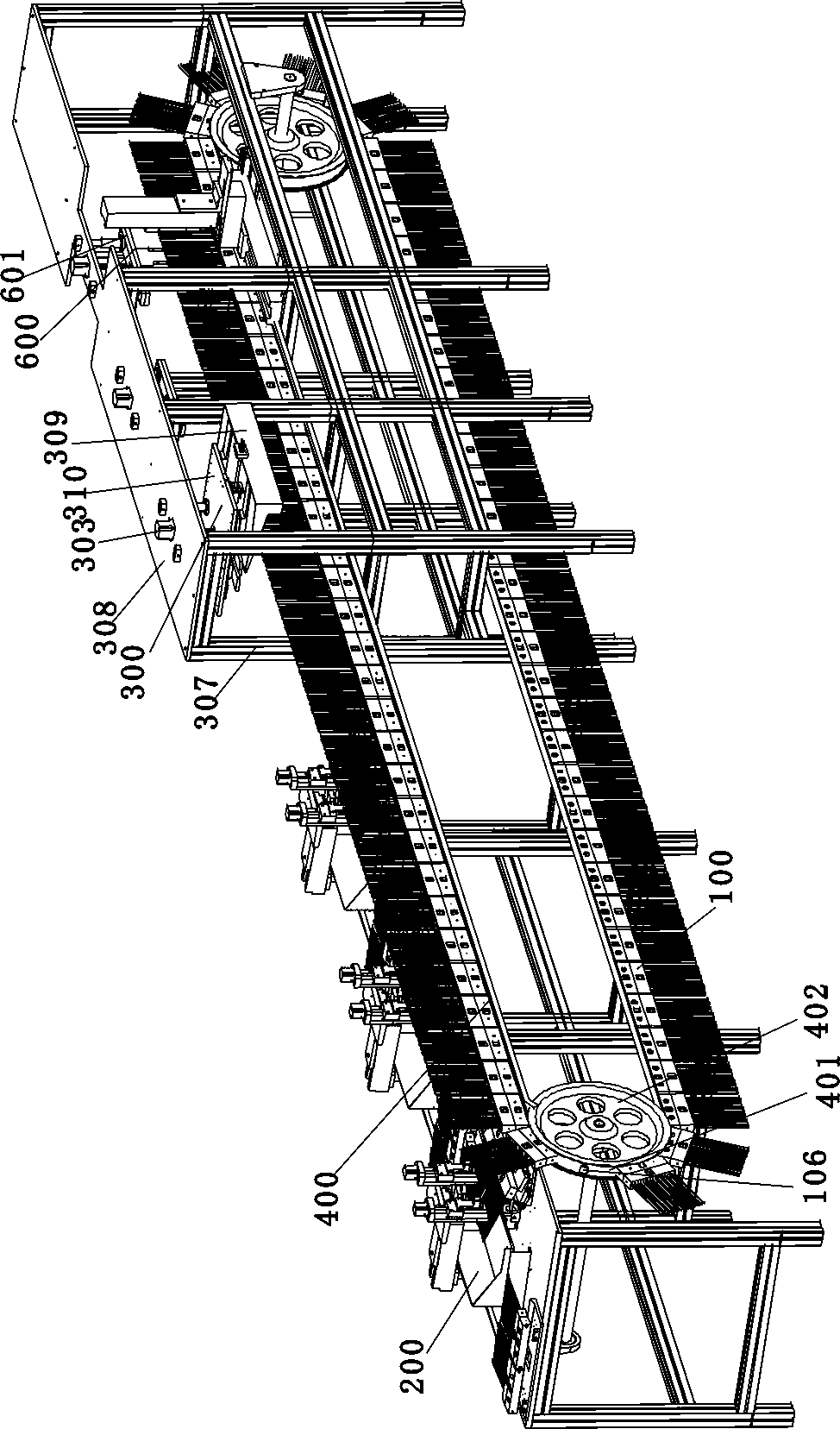

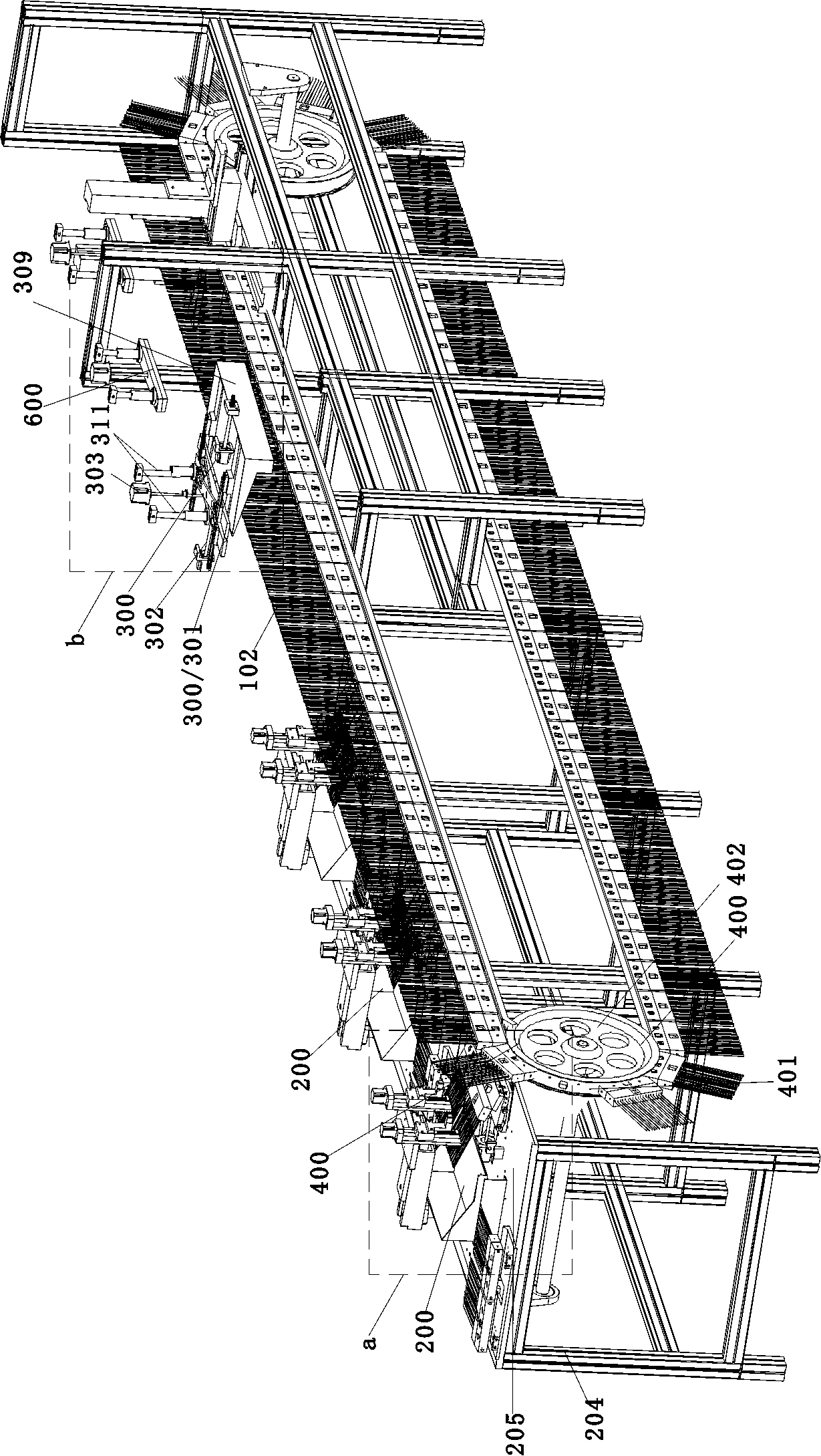

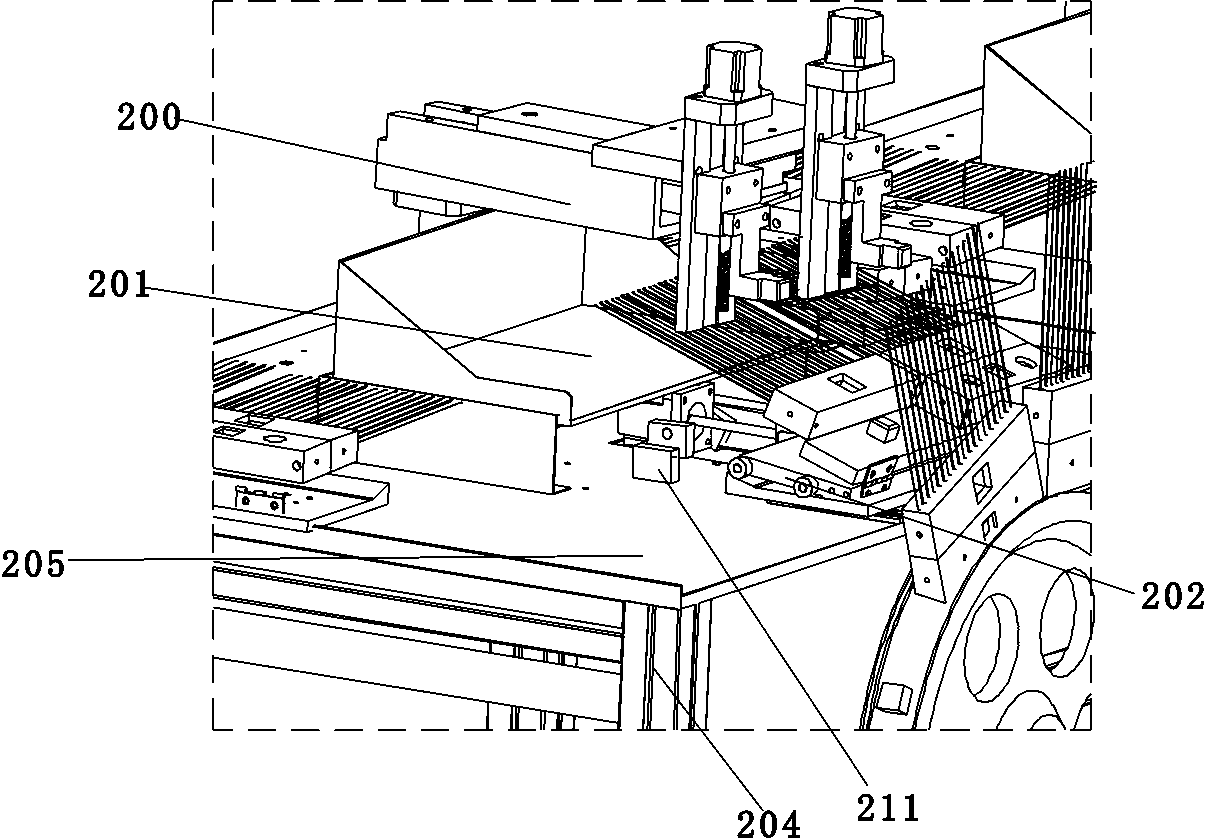

[0040] see Figure 1-15 , the present implementation case includes the bead selector 100 that intersperses and screens the qualified internal diameter beads. The outer diameter of the inner diameter, at least one of the said strain selection rod 102, the said bead selection device 100 is provided with at least one. The bead threading mechanism 200 cooperates with the bead selector 100 to randomly insert loose beads on the plant selection rod 102 of the bead selector 100 . Blocking bead removal mechanism 300 removes unqualified beads blocked on the plant selection bar 102 by clamping or crushing; the unloading station or / and unloading mechanism separates the beads from the plant selection bar 102 or makes the beads rely on their own weight Disengage from the plant selection bar 102 of the inverted bead selector 100, and a blanking mechanism can be set if necessary; (the blanking station and the blanking mechanism are not drawn in the accompanying drawings) the blanking station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com