Structural light projection device

A technology of structured light projection and light, applied in projection devices, optics, optical components, etc., can solve problems such as thermal deformation, low light quality, and poor collimated beam effect of collimating lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

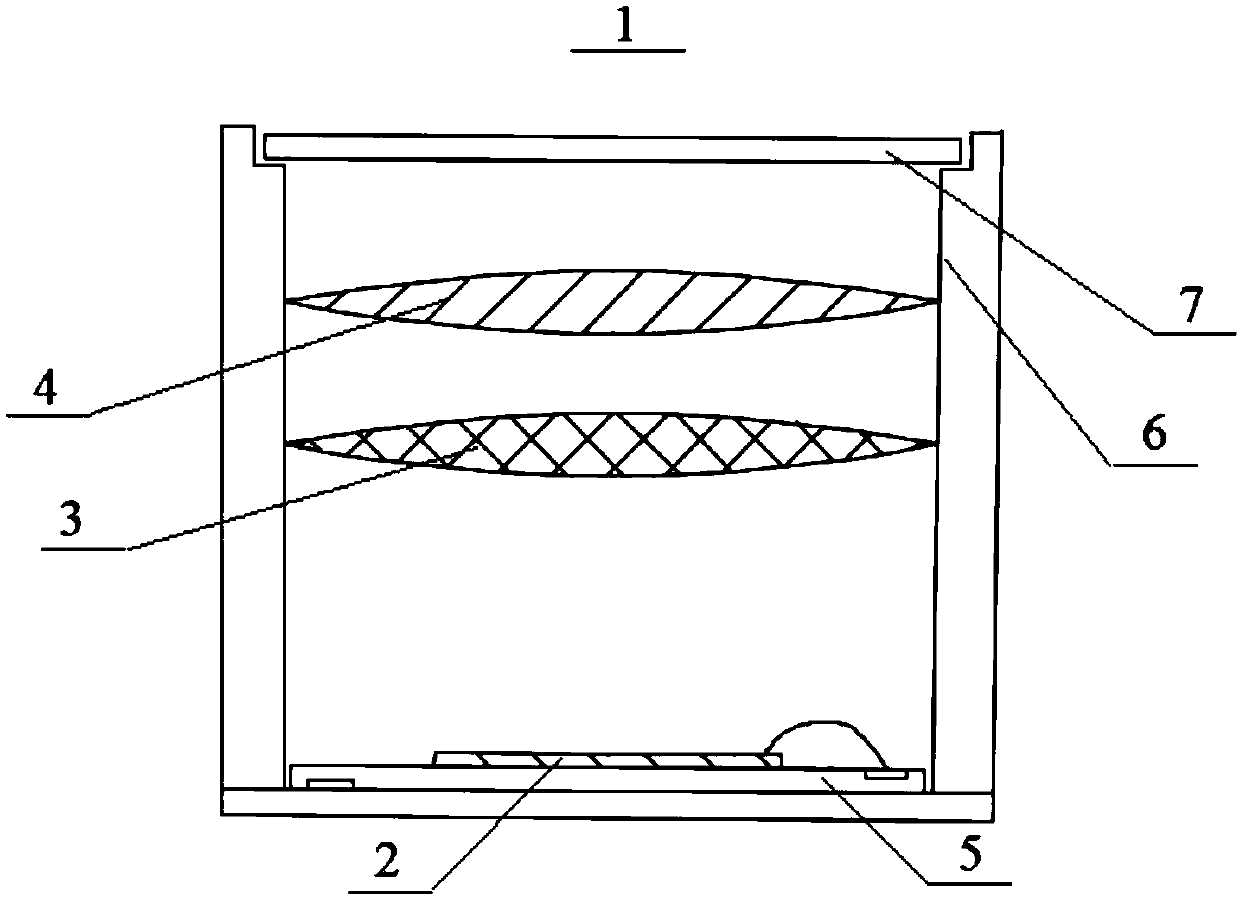

[0080] Refer to the following figure 1 Embodiment 1 of the structured light projection device of the present application will be described.

[0081] Such as figure 1 As shown, Embodiment 1 of the structured light projection device 1 includes a laser emitting part 2 , a first collimating lens 3 and a second collimating lens 4 . The first collimating lens 3 is located on the optical path of the light emitted by the laser emitting part 2 to initially collimate the light emitted by the laser emitting part 2 . The second collimator lens is located on the optical path of the light rays initially collimated by the first collimator lens 3 to re-collimate the light rays initially collimated by the first collimator lens 3 to form parallel light beams. The laser emitting part 2 is located on the plane where the focal point jointly formed by the first collimating lens 3 and the second collimating lens 4 is located.

[0082] In Embodiment 1, the structured light projection device 1 furt...

Embodiment 2

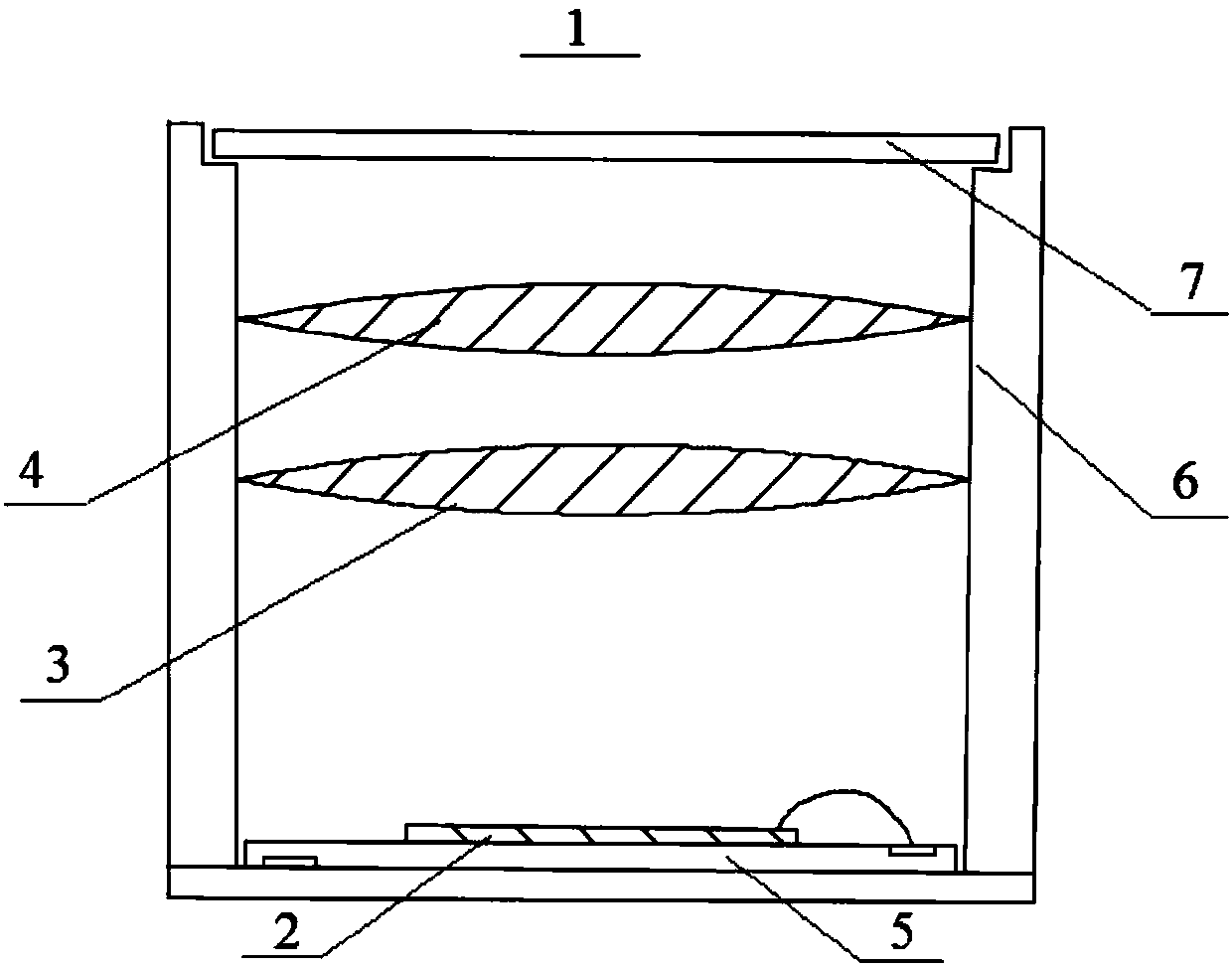

[0088] Refer to the following figure 2 Embodiment 2 of the structured light projection device 1 of the present application is described. Except for the material of the first collimating lens 3 , the arrangement structure of the structured light projection device 1 described in Embodiment 2 and the following Embodiment 3 is the same as that of the structured light projection device described in Embodiment 1. For the sake of brevity, part of the description similar to Embodiment 1 will be omitted.

[0089] figure 2 A schematic structural diagram of the structured light projection device 1 of Embodiment 2 is shown. Such as figure 2 As shown, the first collimating lens 3 and the second collimating lens 4 of the structured light projection device 1 according to Embodiment 2 are both made of a material with high thermal stability, such as glass.

Embodiment 3

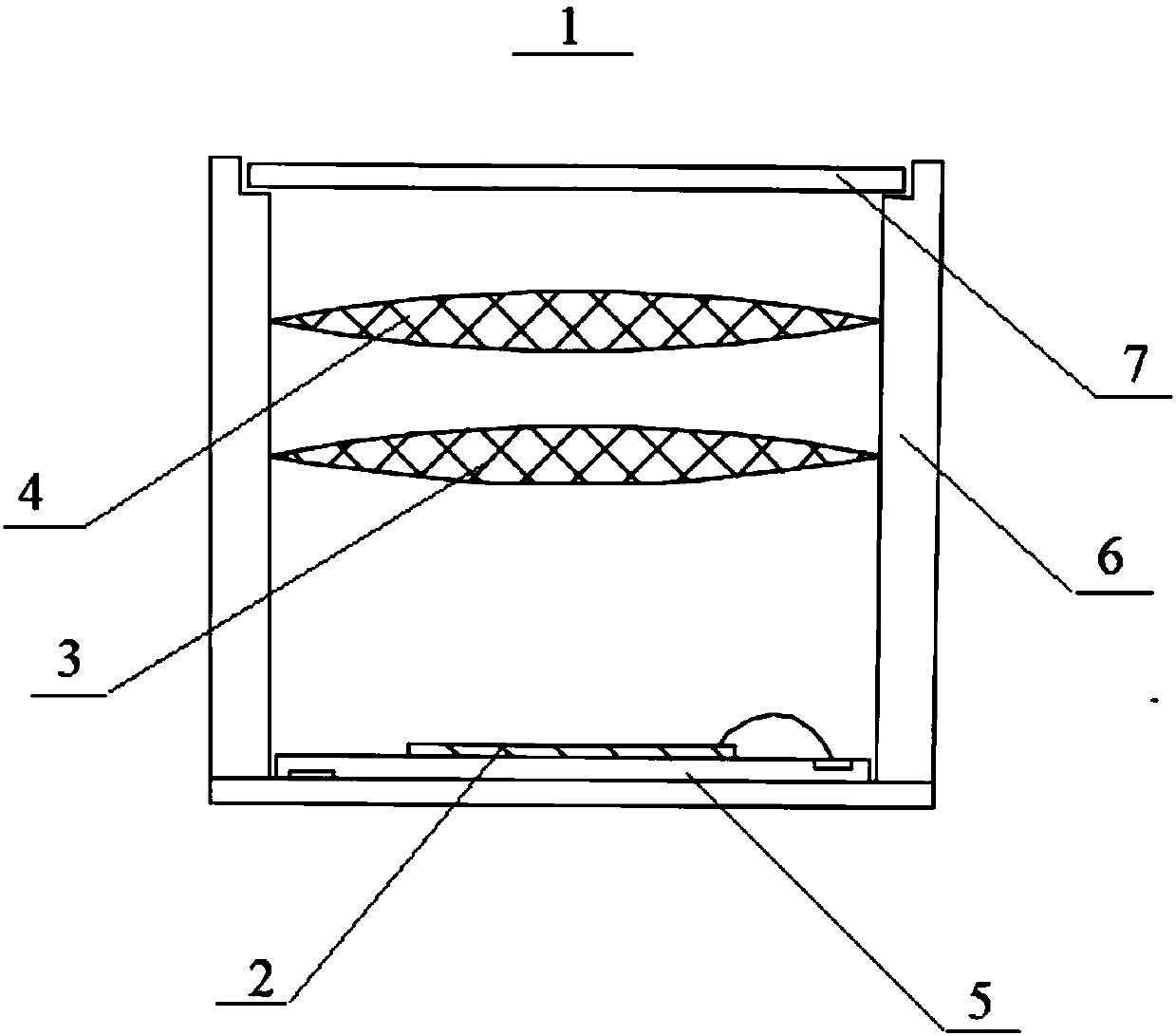

[0091] Refer to the following image 3 Embodiment 3 of the structured light projection device 1 of the present application is described. image 3 A schematic structural diagram of the structured light projection device 1 of Embodiment 3 is shown. Such as image 3 As shown, the first collimating lens 3 and the second collimating lens 4 of the structured light projection device 1 according to Embodiment 3 are both made of conventional collimating lens materials with low thermal stability, such as plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com