Three-phase electric water boiler final-stage control protection device

A technology for control and protection of electric water boilers, applied in the field of final control and protection devices for three-phase electric water boilers, can solve problems such as aging connection lines, high working current, burns, etc., and achieve the effect of preventing accidents and maintaining a safe and silent protection state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

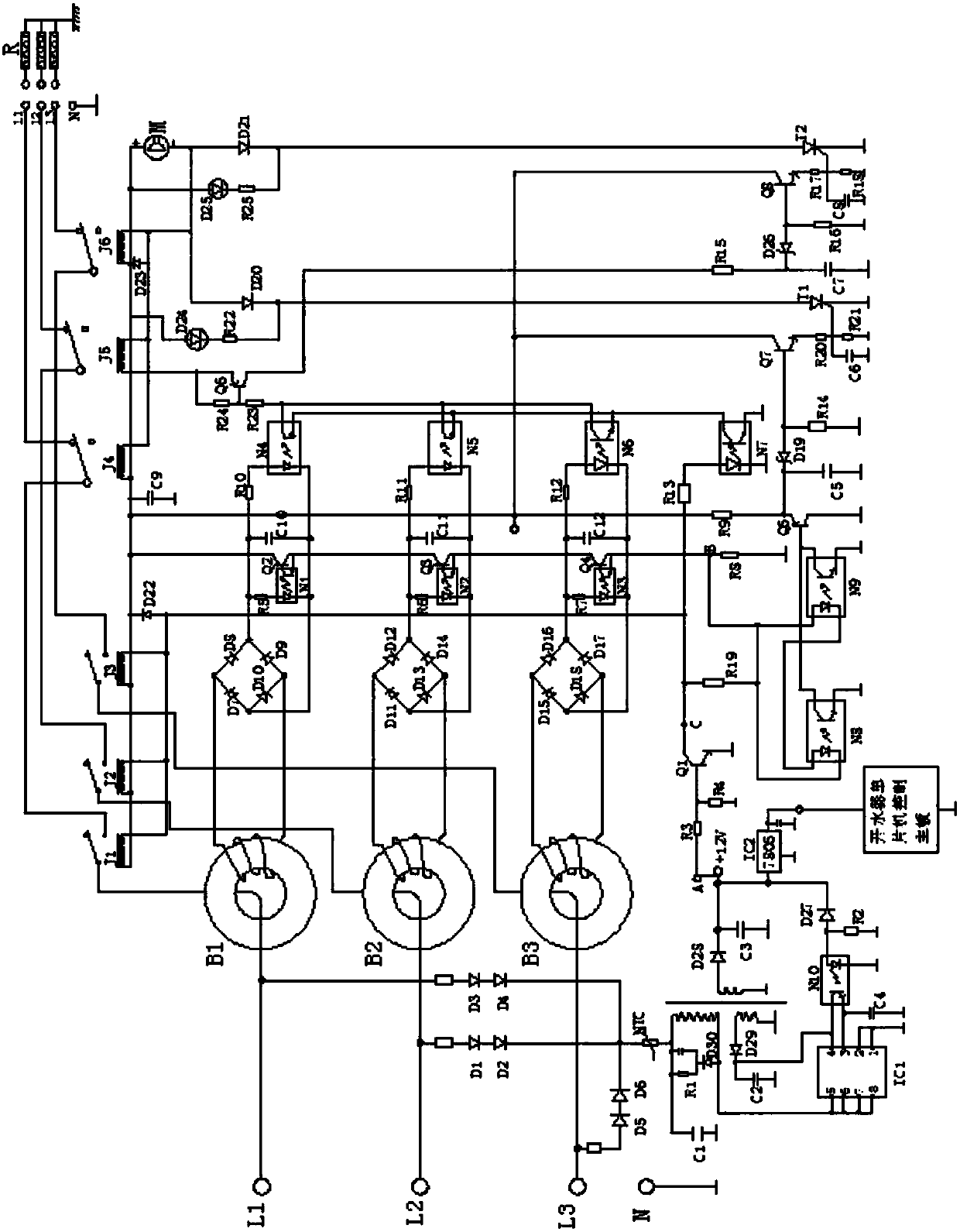

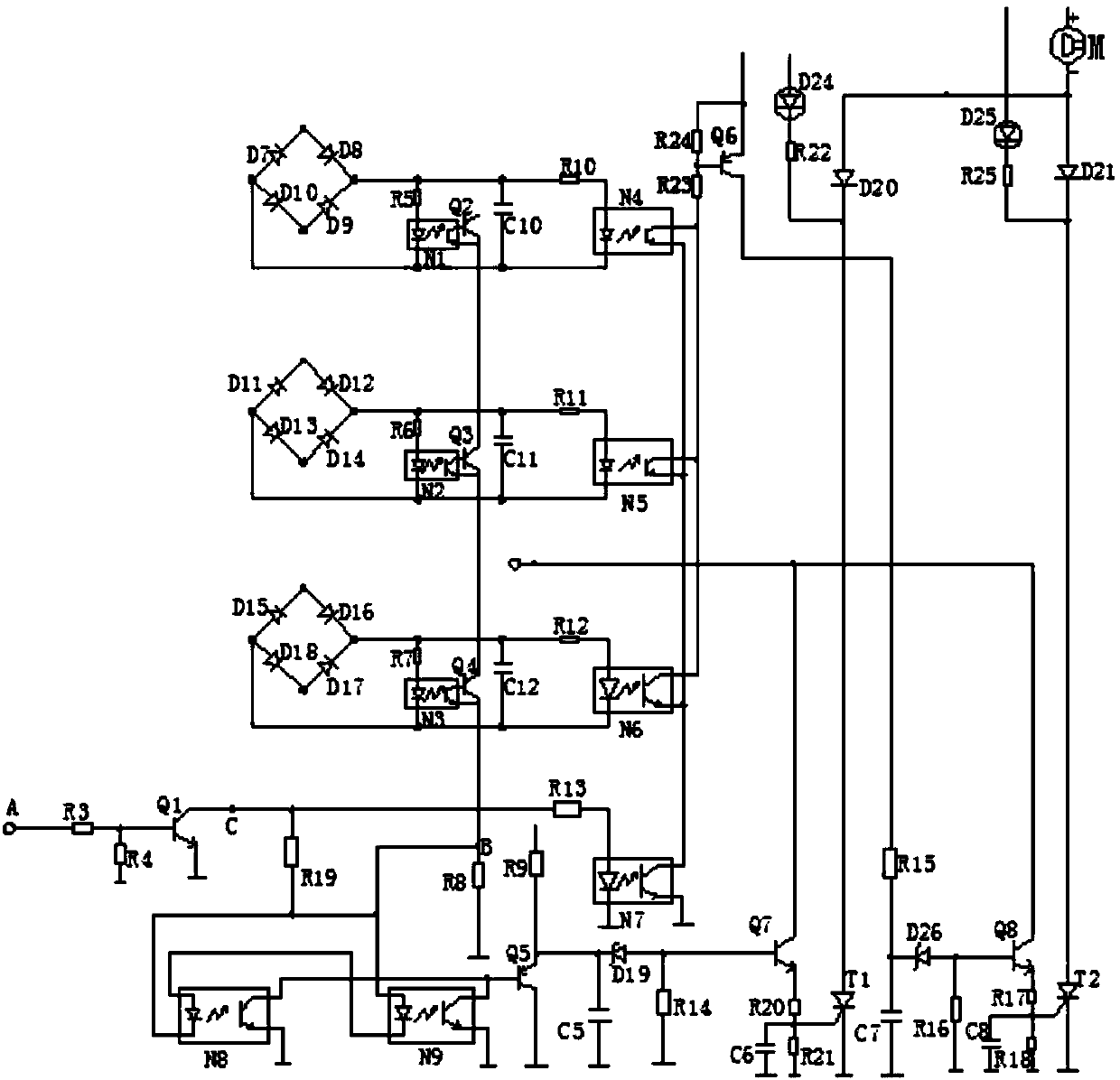

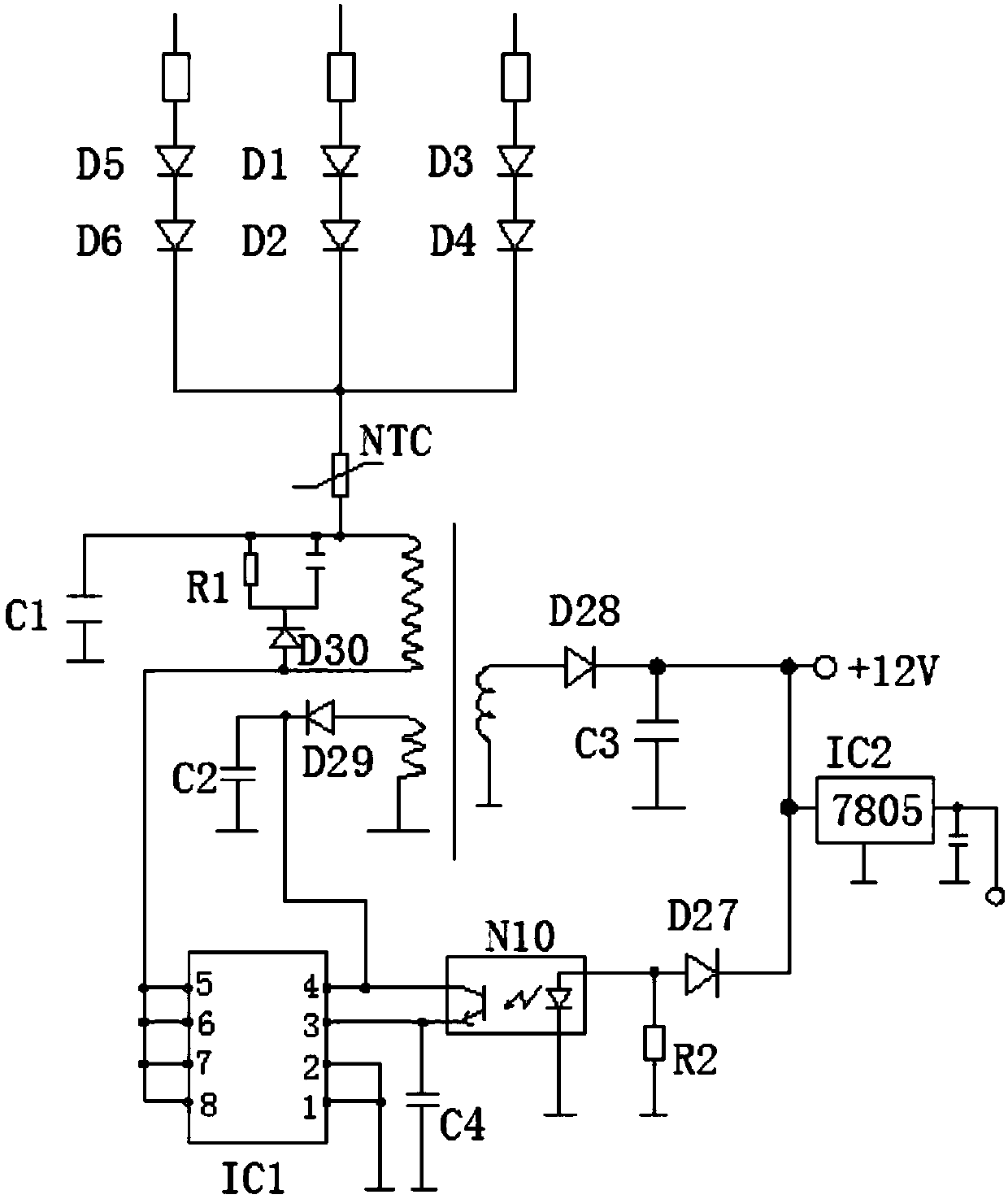

[0012] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples.

[0013] Such as Figure 1-3 As shown, a final control and protection device for a three-phase electric water boiler includes an electric heating tube R of the water boiler, working relays J1, J2, J3, protection relays J4, J5, J6, mutual inductors L1, L2, L3, and a protection circuit. It is characterized in that: one end of the electric heating tube R of the water boiler is connected to the zero line of the power supply, and the other end is connected in parallel with three wires, and each wire is respectively provided with working relays J1, J2, J3 and protection relays J4, J5, J6, The protective relays J4, J5, J6 are arranged on one side close to the electric heating tube R, and the other side of the protective relays J4, J5, J6 are connected with working relays J1, J2, J3, and the working relays J1, J2, J3 The wires at the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com