Non-contact coal mine conveyor belt deviation protection method and device

A non-contact, conveyor technology, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problem that the deviation protection cannot work normally, the micro switch contacts are easily oxidized, and the deviation protection sealing is poor, etc. problems, to achieve the effect of reducing investment and workload of maintenance personnel, sensitive protection actions, and reducing electromechanical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

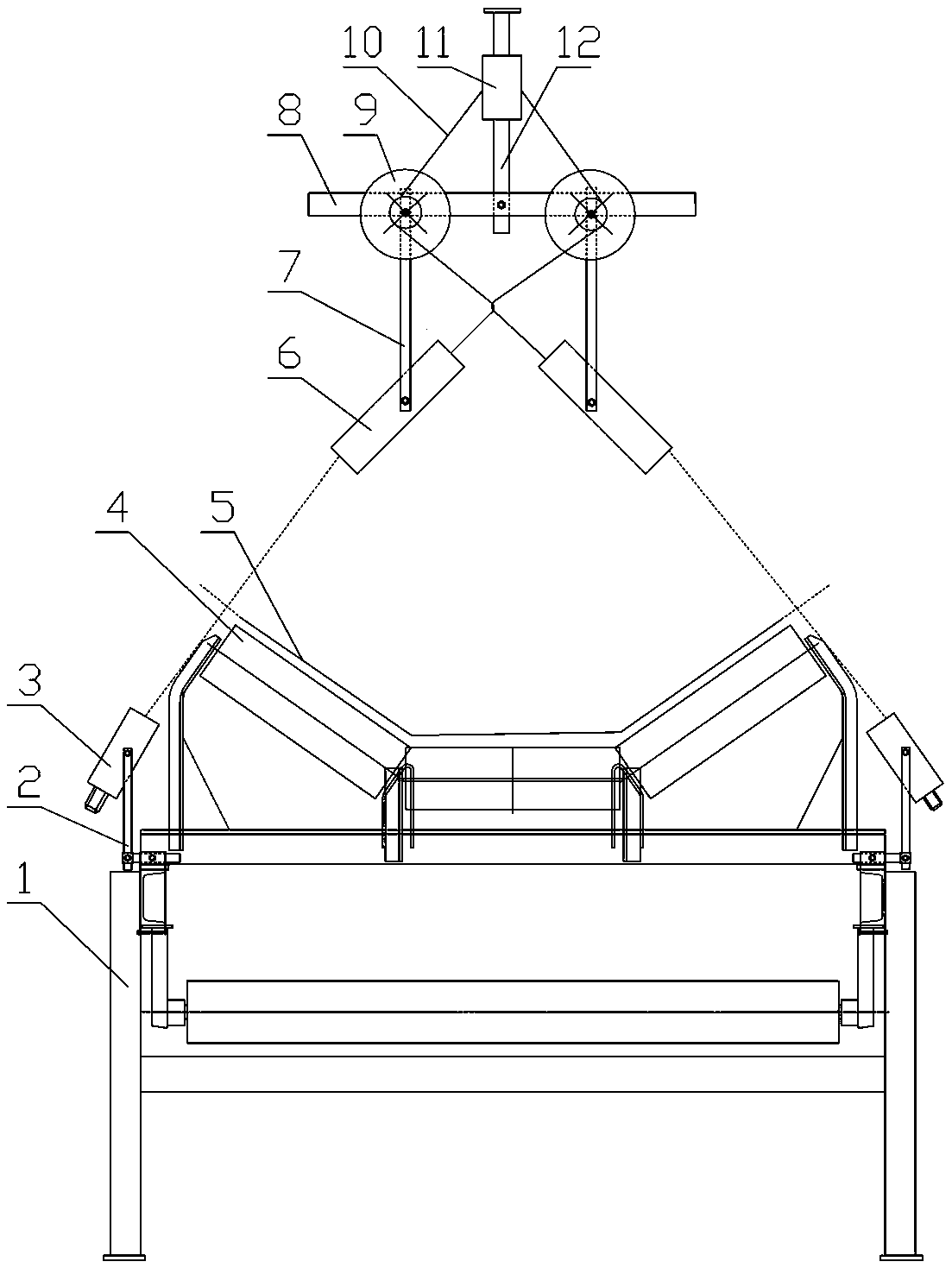

[0024] Example: see figure 1 , in the figure, 1-conveyor, 2-lower fixed frame, 3-infrared receiver, 4-idling roller, 5-tape, 6-infrared transmitter, 7-pole, 8-horizontal bar, 9-wire reel , 10-wire, 11-controller, 12-hanging rod.

[0025] The non-contact coal mine conveyor belt deviation protection device contains an infrared transmitter 6 and an infrared receiver 3, of which: two infrared transmitters 6 and two infrared receivers 3, and two infrared receivers 3 pass through the lower fixing frame 2 respectively installed on the longitudinal beams on both sides of the conveyor 1, the middle parts of the two infrared emitters 6 are respectively connected to the lower ends of the two vertical rods 7 in a rotational manner, and the upper ends of the two vertical rods 7 are respectively connected to the cross bar 8, and the cross bar The middle upper end of 8 is connected with the lower end of the boom 12, the boom 12 is provided with a controller 11, the upper end of the boom 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com