Motor rotor magnetic steel gluing assembly hand and system

A motor rotor and gluing technology, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve the problems of difficult insertion of glue needles, difficult control, and high labor intensity for manual insertion of magnetic steel sheets. To achieve the effect of automatic operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

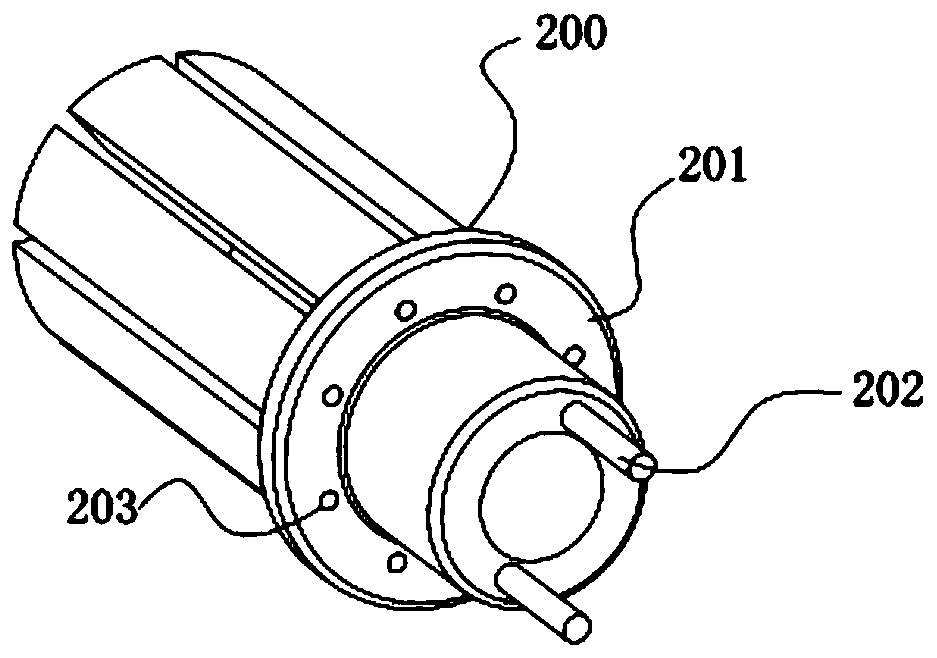

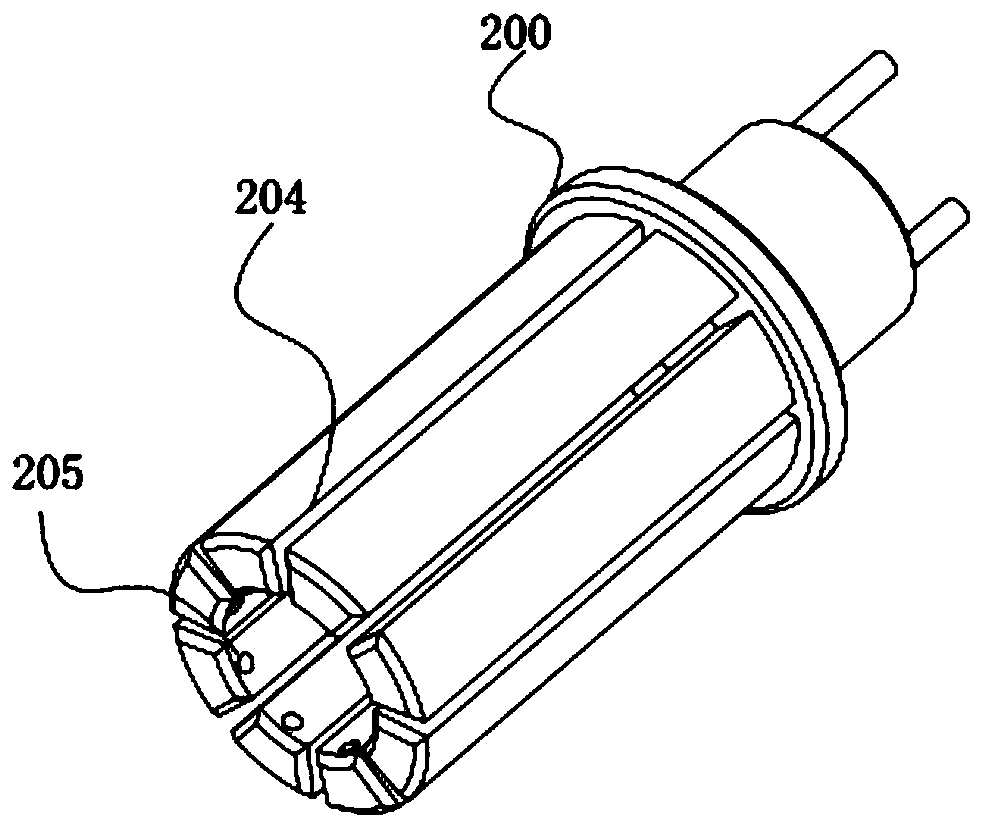

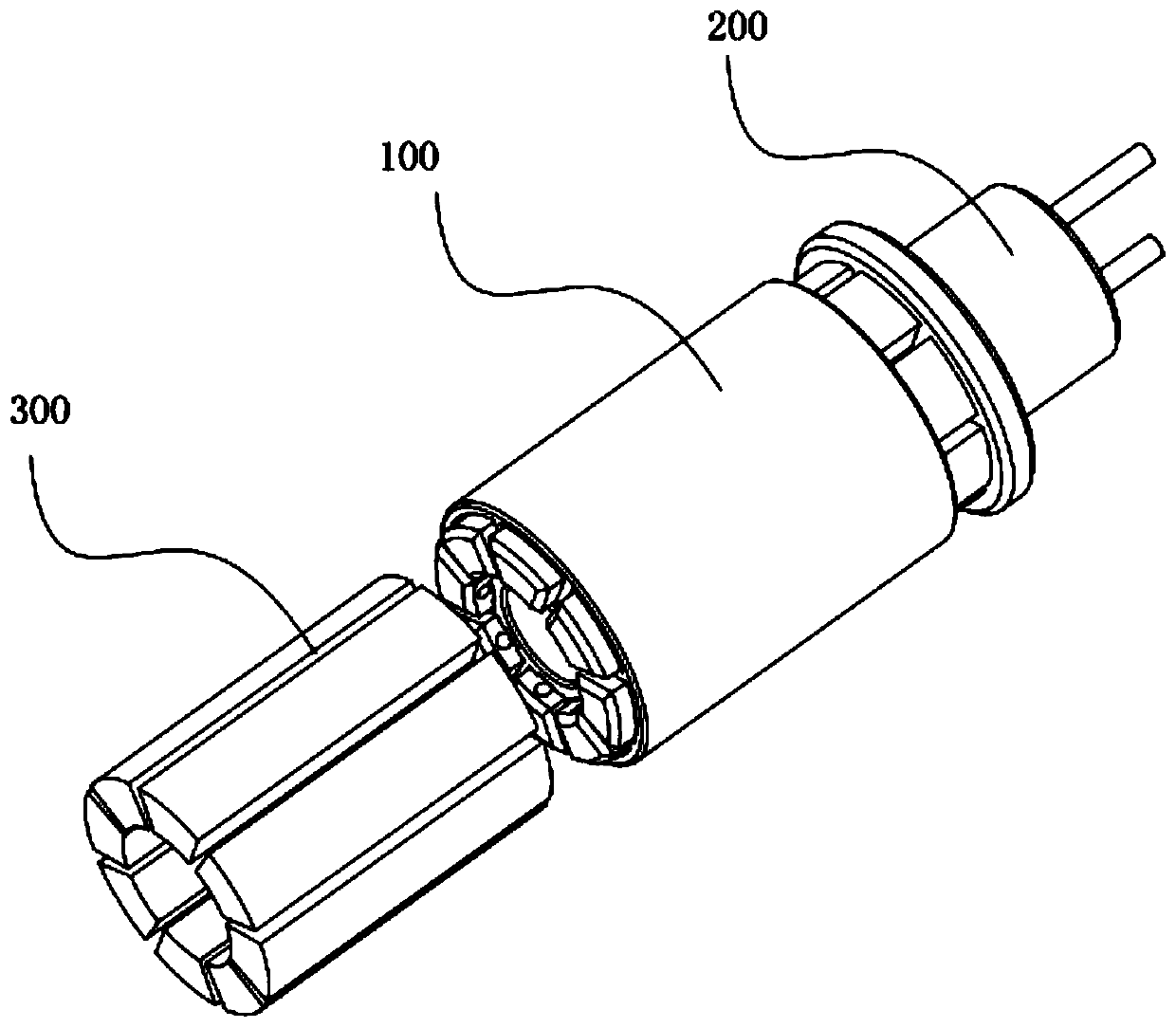

[0021] see Figure 1~4 , in the embodiment of the present invention, a motor rotor magnetic steel gluing assembly hand includes a gluing assembly mechanism 200, specifically, the gluing assembly mechanism 200 includes a sol disk 201 and a glue injection sheet 204, here, the A plurality of injection sheets 204 are installed on the sol tray 201, and the sol tray 201 is provided with an injection hole 203 corresponding to each of the injection sheets 204. Of course, the injection sheets 204 and the magnetic steel sheets 300 are profiled and the injection sheets 204 It can be attracted with the magnetic steel sheet 300 by magnetic force, and the number and arrangement position of the injection film 204 need to be consistent with the magnetic steel sheet 300 to be assembled and fixed, so that the film injection sheet 204 can be inserted into the magnetic steel sheet installation hole in the rotor 100 , under normal circumstances, the magnetic steel sheet 300 is pasted on the outsid...

Embodiment 2

[0026] In an embodiment of the present invention, a motor rotor magnet gluing assembly system includes the motor rotor magnet gluing assembly hand as described in Embodiment 1, and in this system, it can be designed to drive the motor rotor gluing assembly The moving mechanism of the hand is used to realize the automatic movement of the motor rotor magnetic steel gluing assembly hand to achieve efficient magnetic steel assembly.

[0027] It should be noted that, in this technical solution, the gluing assembly mechanism 200 that fits with the rotor and the magnetic steel sheet can be used to perform gluing assembly of multiple magnetic steel sheets 300 at one time, with high efficiency, and the electrodes or magnetic poles It can be controlled to realize automatic operation.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap