Compound type minimal-tillage combined operation machine and use method thereof

A combined operation machine and compound technology, applied in the field of agricultural machinery, can solve the problems of good plowing effect and the inability of ordinary operation machines to treat residues at the same time, and achieve good plowing effect, reduced steps, and high degree of integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

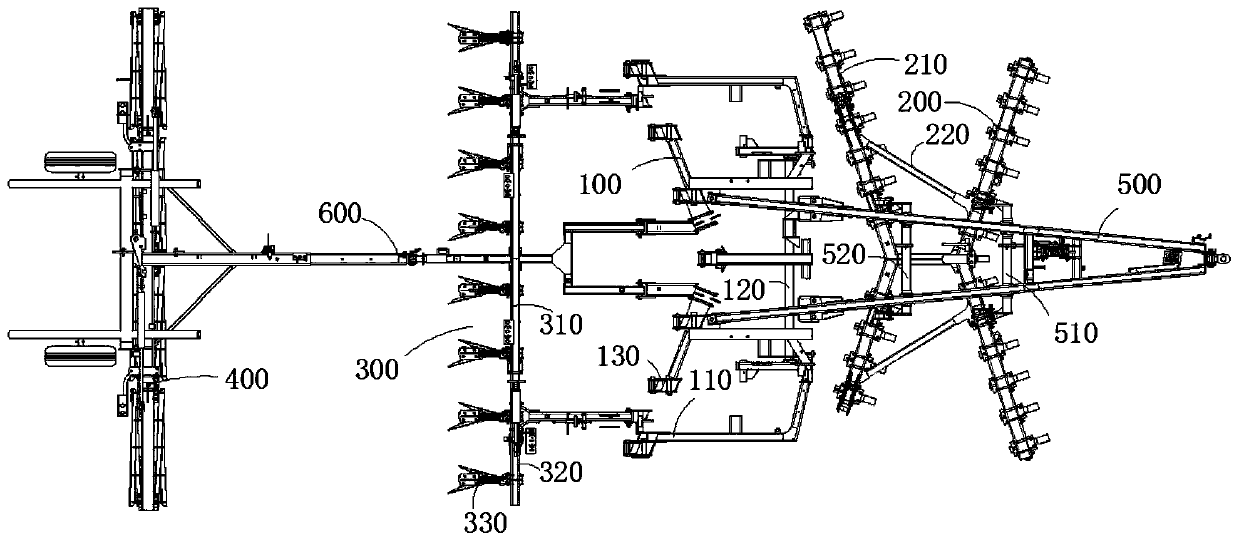

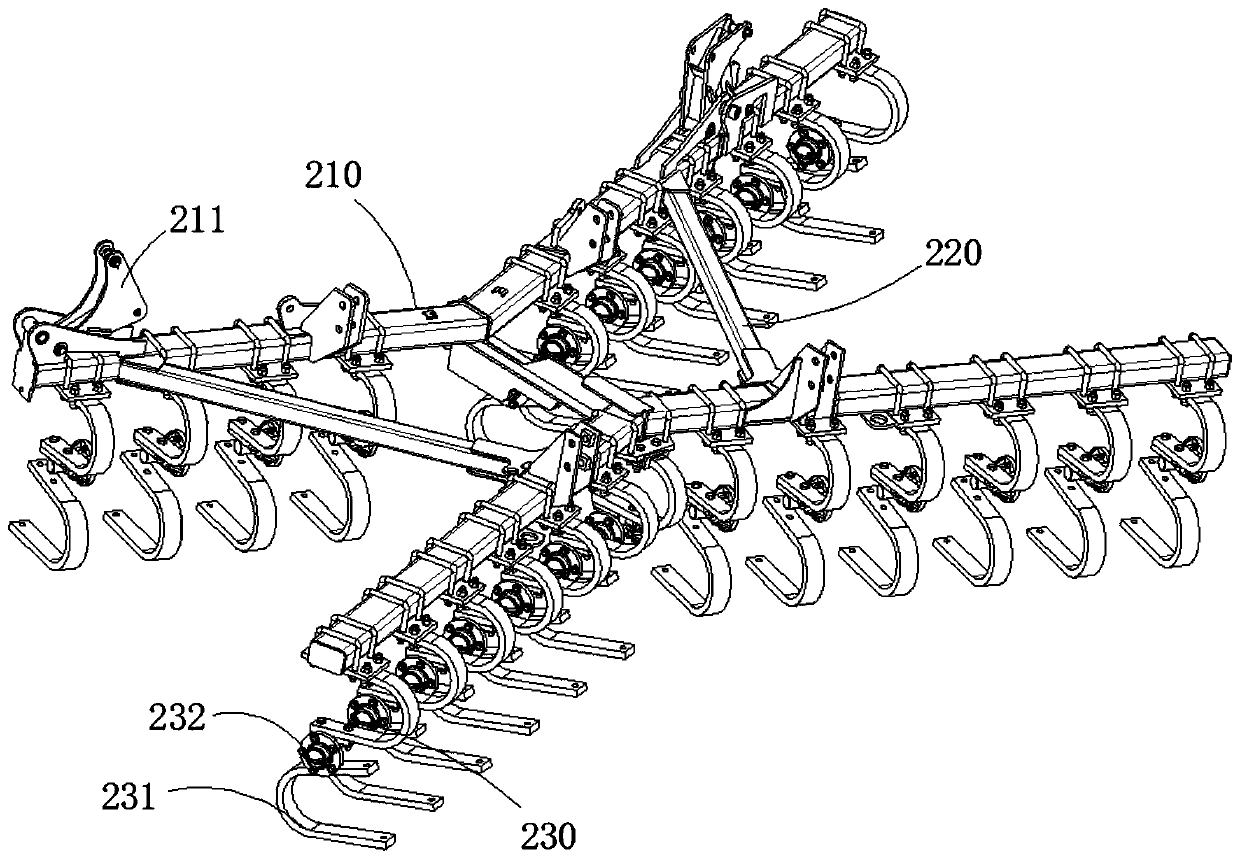

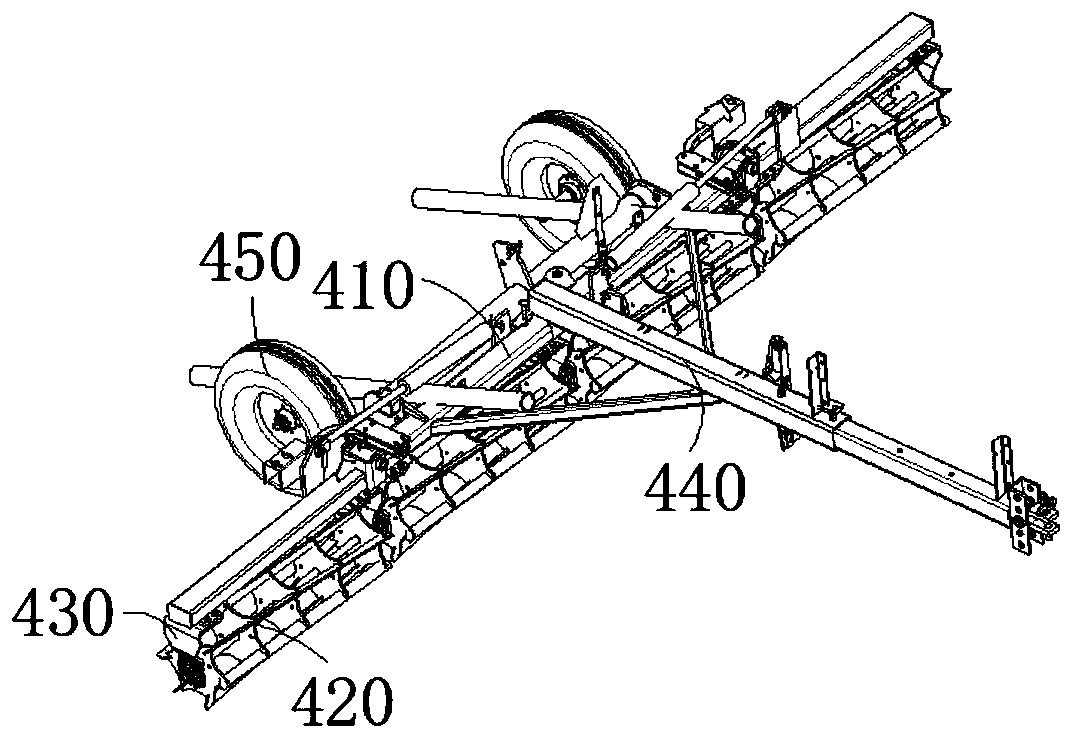

[0043] Refer to attached figure 1 , figure 2 and image 3As shown, a compound less-tillage combined operation machine in this embodiment includes a frame 100, a rake group assembly 200, a wet soil assembly 300 and a soil crushing assembly 400, the front end of the frame 100 is fixedly connected to the traction frame 500, and the rake group assembly 200 Located below the traction frame 500 and fixedly connected to the traction frame 500, the rear end of the frame 100 is fixedly connected to the combined assembly 300, the rear of the combined assembly 300 is provided with a broken soil assembly 400, and the broken soil assembly 400 is fixedly connected to the frame 100 through a tie rod 600 , the rake group assembly 200, moisture collection assembly 300 and soil crushing assembly 400 are arranged longitudinally, and the pull rod 600 is located on the symmetrical axis of the moisture collection device. If one frame 100 is operated separately, the whole tillage step becomes com...

Embodiment 2

[0051] Refer to attached figure 1 , figure 2 , image 3 and Figure 4 As shown, the use method of a compound less-tillage combined operation machine in this embodiment is that the traction frame 500 is connected to the tractor, the tractor drives the operation machine forward, 200 harrow groups are assembled to cultivate the land, and 300 pairs of soil moisture are assembled. The cultivated land is kept moisture and leveled, and the soil crushing device crushes and compacts the large soil clods that have been plowed.

[0052] The usage method of this embodiment includes the following steps:

[0053] S100, drive, the traction frame 500 is connected to the tractor, and the tractor drives the entire working machine forward to drive the various components in the working machine to work;

[0054] S200, plowing, the harrow assembly 200 plows the soil, and the harrow assembly 230 is embedded in the soil to turn up the soil;

[0055] S300, combining moisture, the moisture combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com