Waste gas dust recovery device for forging blank electric slag furnace

A technology of dust recovery and electroslag furnace, which is applied in the direction of dust removal, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of limited effect, pollution, loud noise, etc., and achieve convenient air volume, good absorption effect, and easy adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

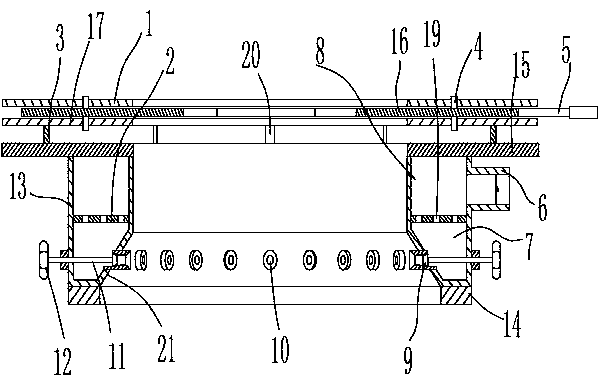

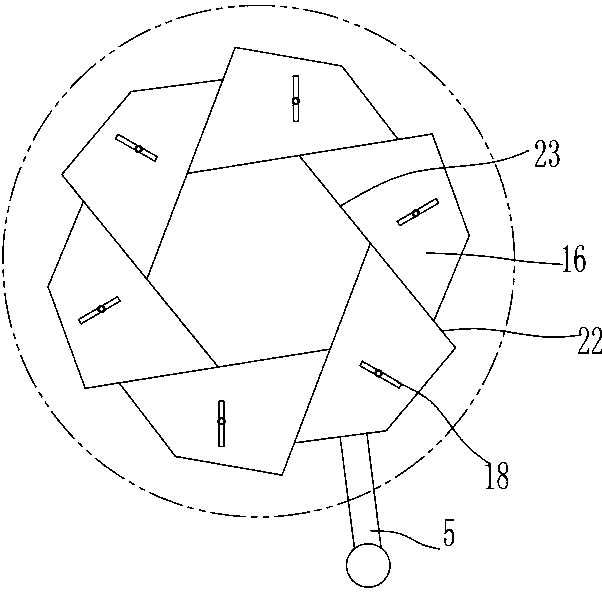

[0019] Embodiment: an exhaust gas and dust recovery device for forging blank electroslag furnace, comprising an annular negative pressure ring 13, an annular base plate 15 arranged on the top of the negative pressure ring 13, and a necking mechanism arranged on the top of the annular base plate 15, The negative pressure ring 13 is provided with an annular negative pressure chamber, the inner wall of the negative pressure ring 13 is provided with a negative pressure port 10 communicating with the negative pressure chamber, and the negative pressure ring 13 is threadedly connected with a tuyere adjusting bolt 11. The head of the tuyere adjusting bolt 11 is provided with an air volume plug 9 extending into the negative pressure opening 10, and the tail end of the tuyere adjusting bolt 11 protrudes from the outer wall of the negative pressure ring 13 and is provided with a knob 12. One side of the negative pressure ring 13 is provided with a suction main pipe 6 communicating with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com