Pipe fitting connection rapid clamping device and application method thereof

A technology for clamping devices and pipe fittings, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inflexible pipe welding processing operations and inability to freely rotate pipe fittings, and achieve stable adjustment and high operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

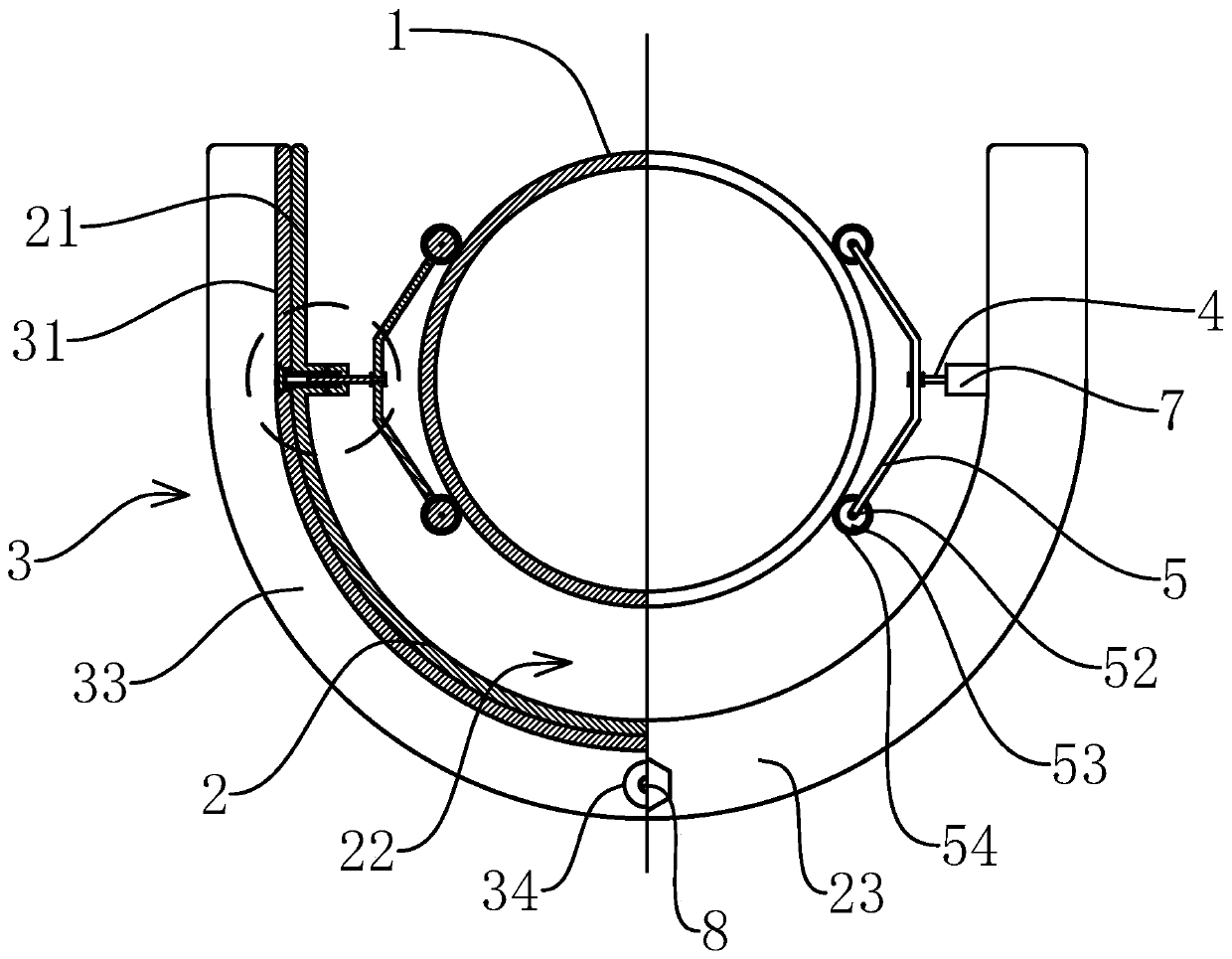

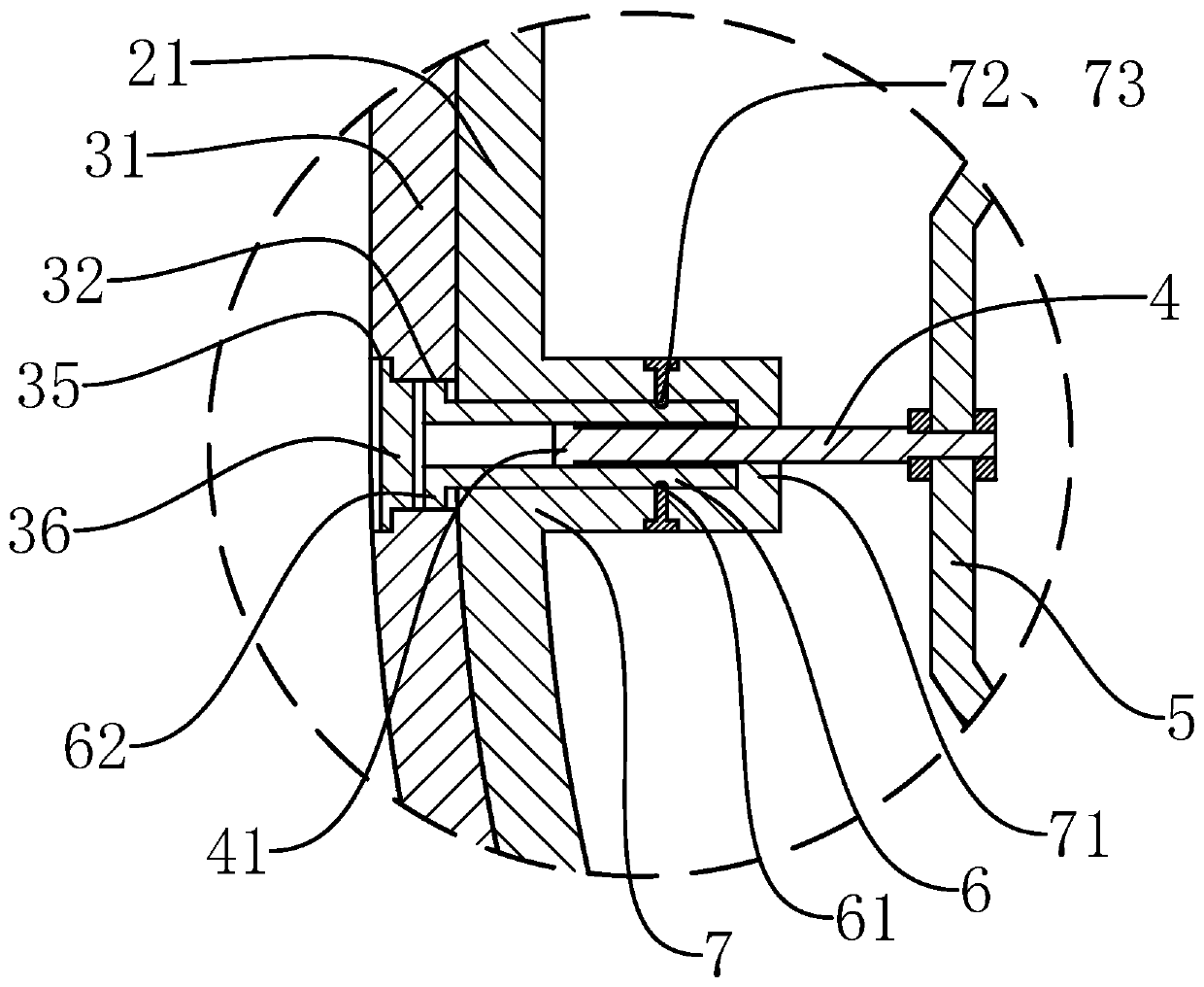

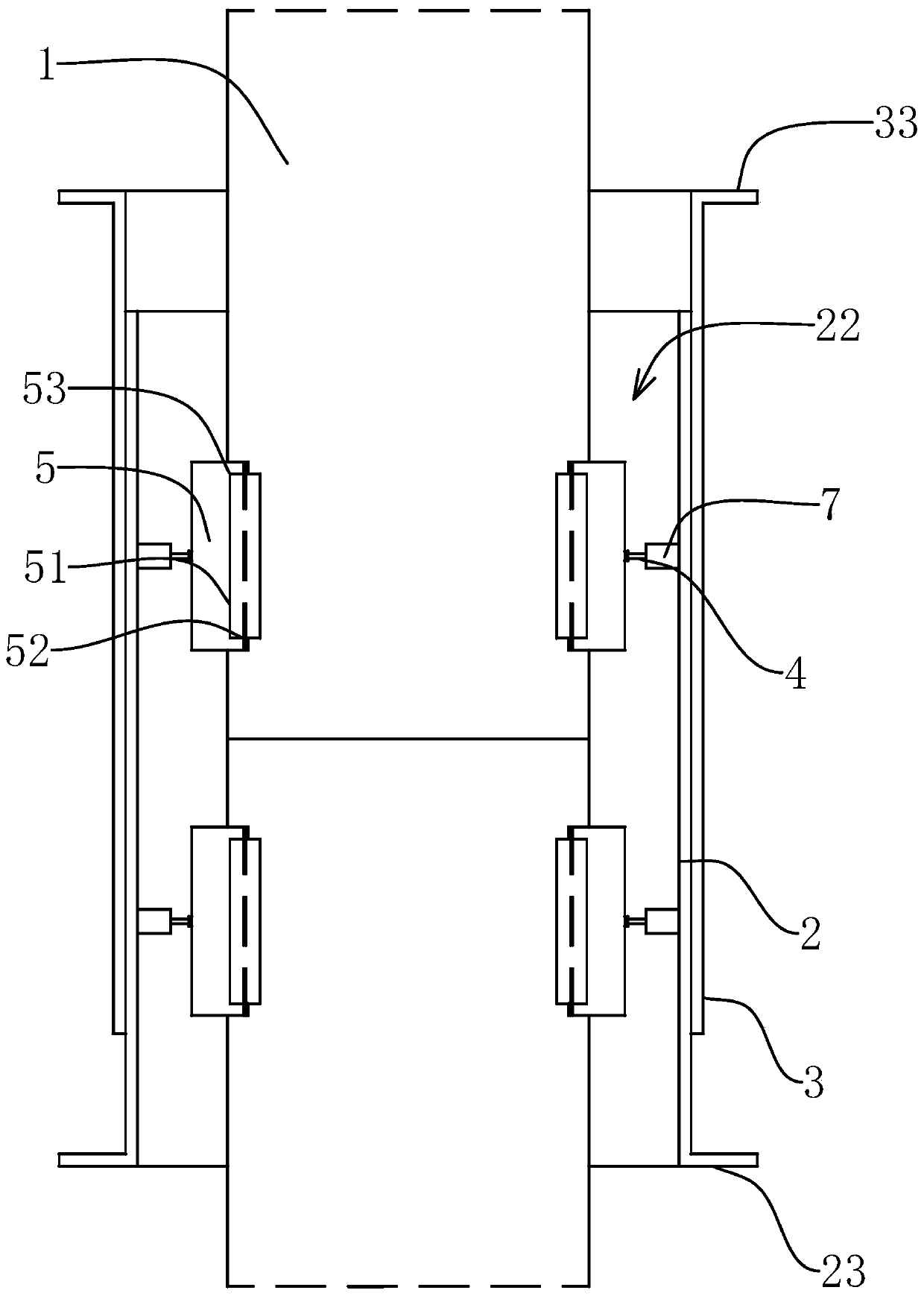

[0042] Such as Figure 1-4As shown, the present invention is a quick clamping device for connecting pipe fittings, which is used for clamping two round tubular pipe fittings 1 to be connected. There are two inner seat plates 21 parallel to each other on the support 2, and two outer seat plates 31 parallel to each other are provided on the outer support 3, and the opposite inner surfaces of the two outer seat plates 31 are respectively connected to the two inner seat plates 21. The opposite outer sides slide and fit together, and the inner support 2 has a slotted clamping groove 22 whose length direction is parallel to the inner seat plate 21. It also includes four clamping mechanisms, and two of them form a group. And one...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap