Method for designing large-scale marine rudder horn

A design method, the technology of hanging the rudder arm, applied in the direction of ship propulsion, ship construction, ship parts, etc., to achieve the effects of good matching, improved course stability and reduced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

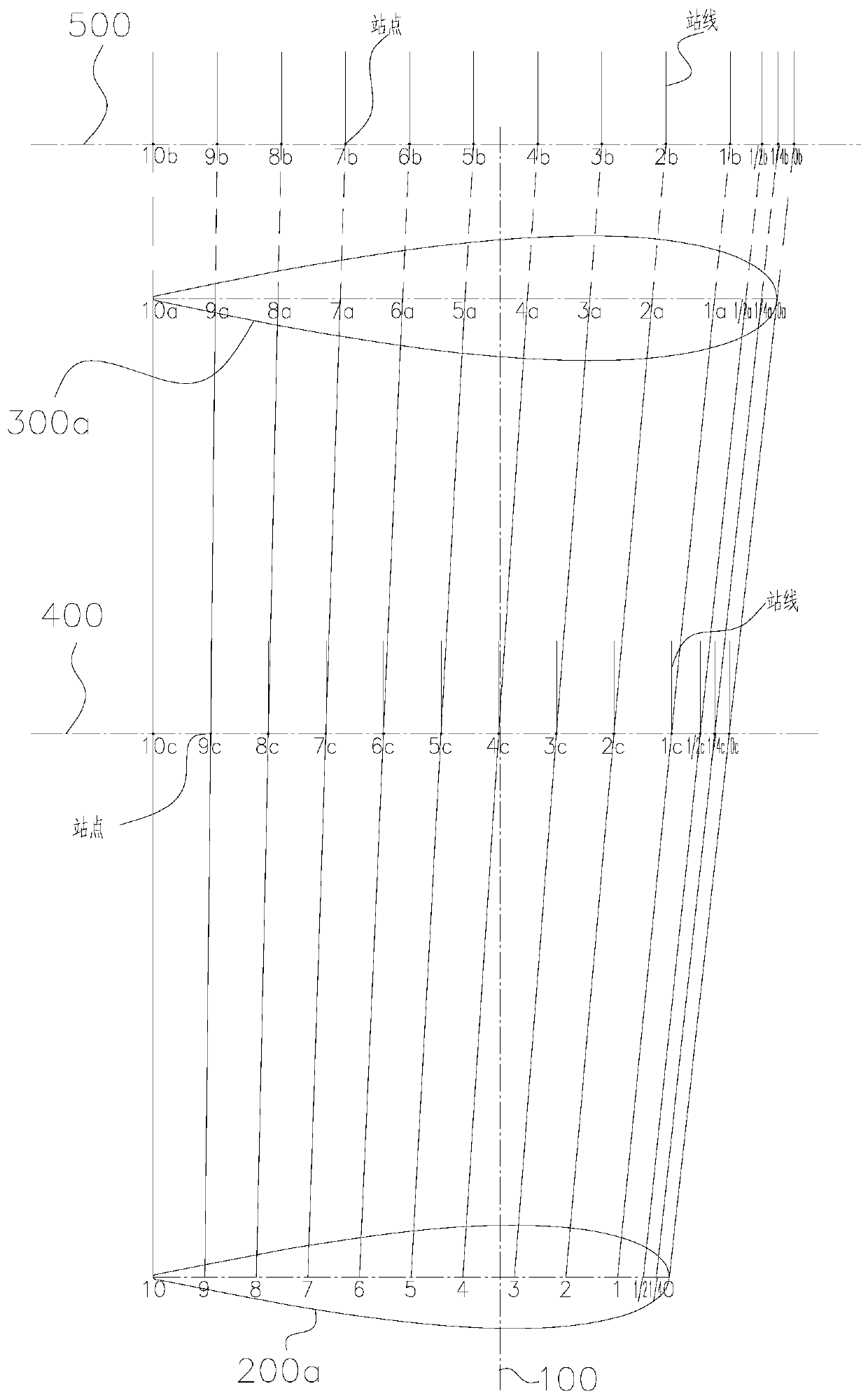

[0034] see Figure 2 to Figure 5 , the design method of a kind of large ship rudder arm of the present invention, comprises the following steps:

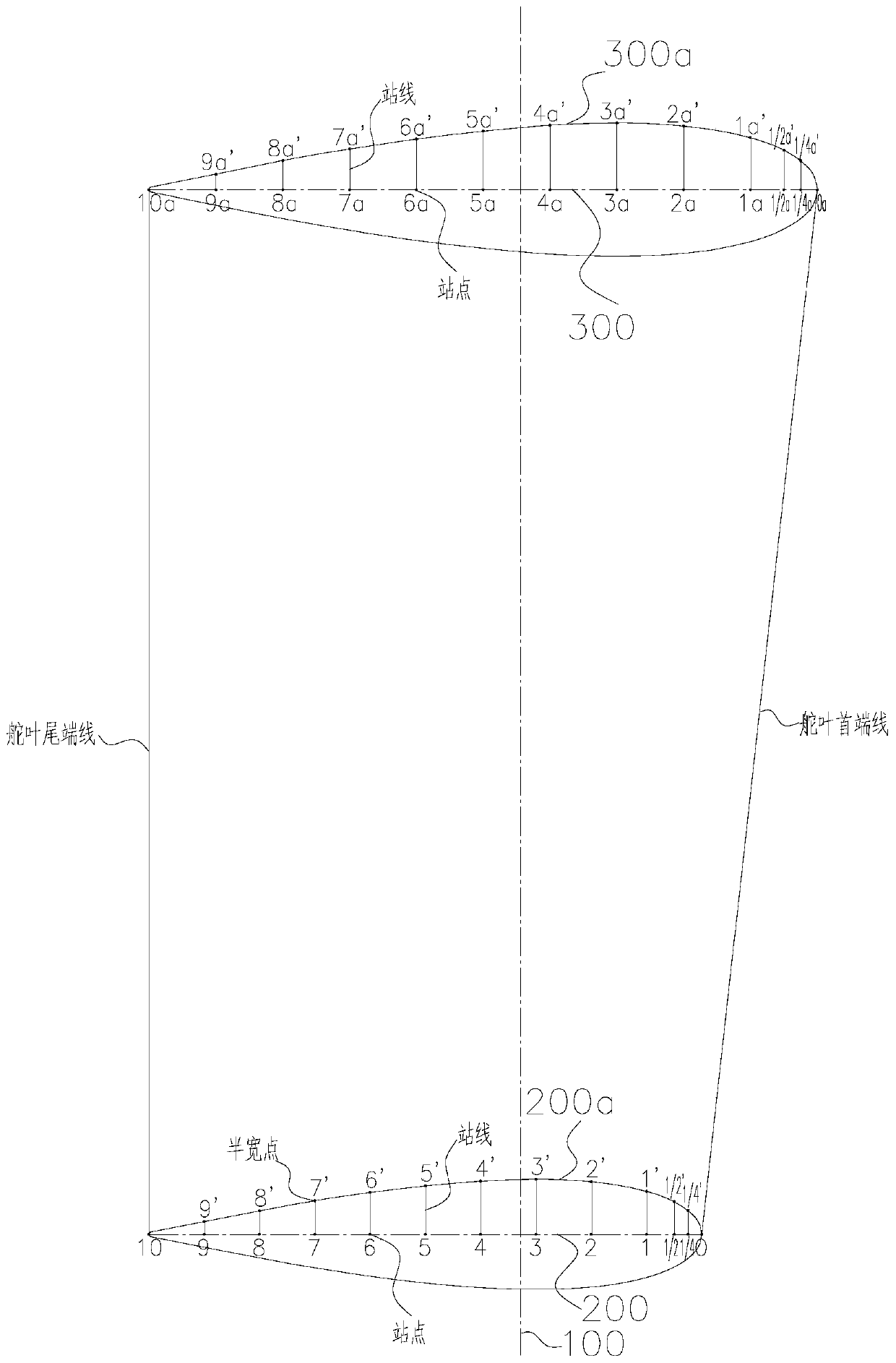

[0035] Step 1, according to the rudder blade design drawing and the rudder blade type value table and marked dimensions on the rudder blade design drawing, draw the contour line of the rudder blade according to the following procedures:

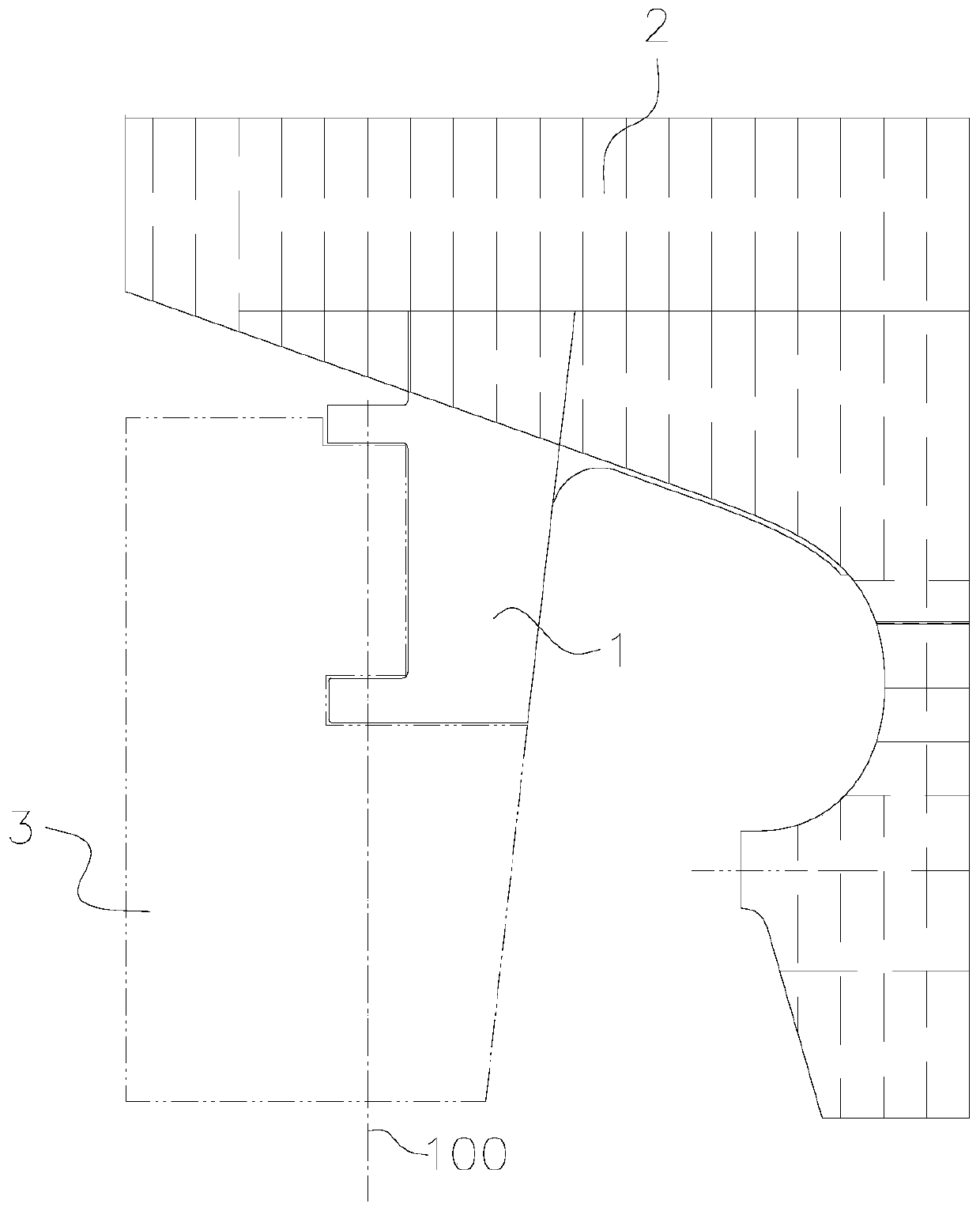

[0036] (1) First draw the center line 100 of the rudder stock, and then draw the center line 200 of the bottom plate of the rudder blade and the center line 300 of the top plate of the rudder blade perpendicular to the center line 100 of the rudder stock respectively according to the dimensions marked on the design drawing of the rudder blade;

[0037] (2) According to the length of the bottom plate of the rudder blade marked on the design drawing of the rudder blade, intercept the front end po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com