Combined counterweight structure and crawler crane with same

A technology of balance weight and balance mechanism, applied in the direction of cranes, etc., can solve the problems of inability to walk on narrow roads, offset of the center of gravity of the main engine, and difficult disassembly of the balance weight, and achieve the effect of improving walking passability and reducing width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

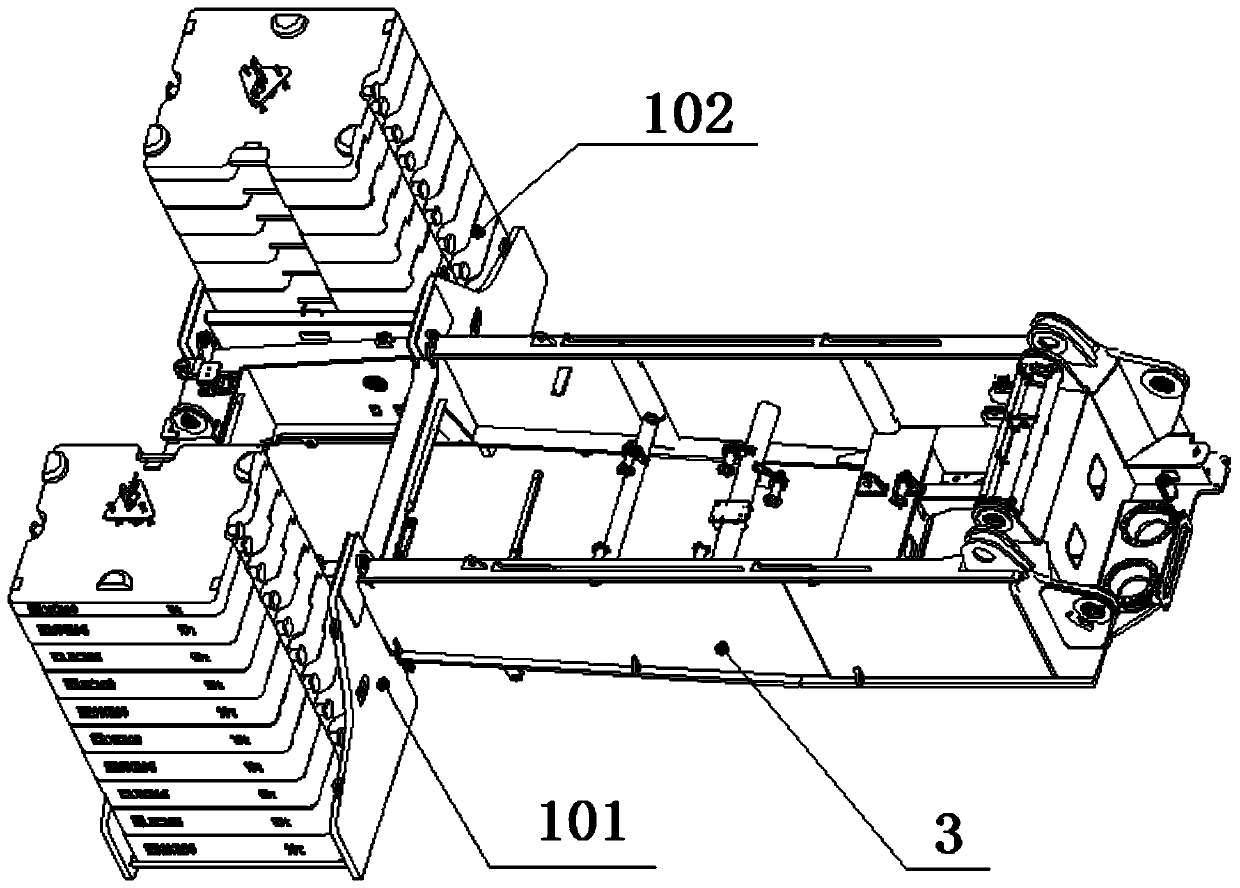

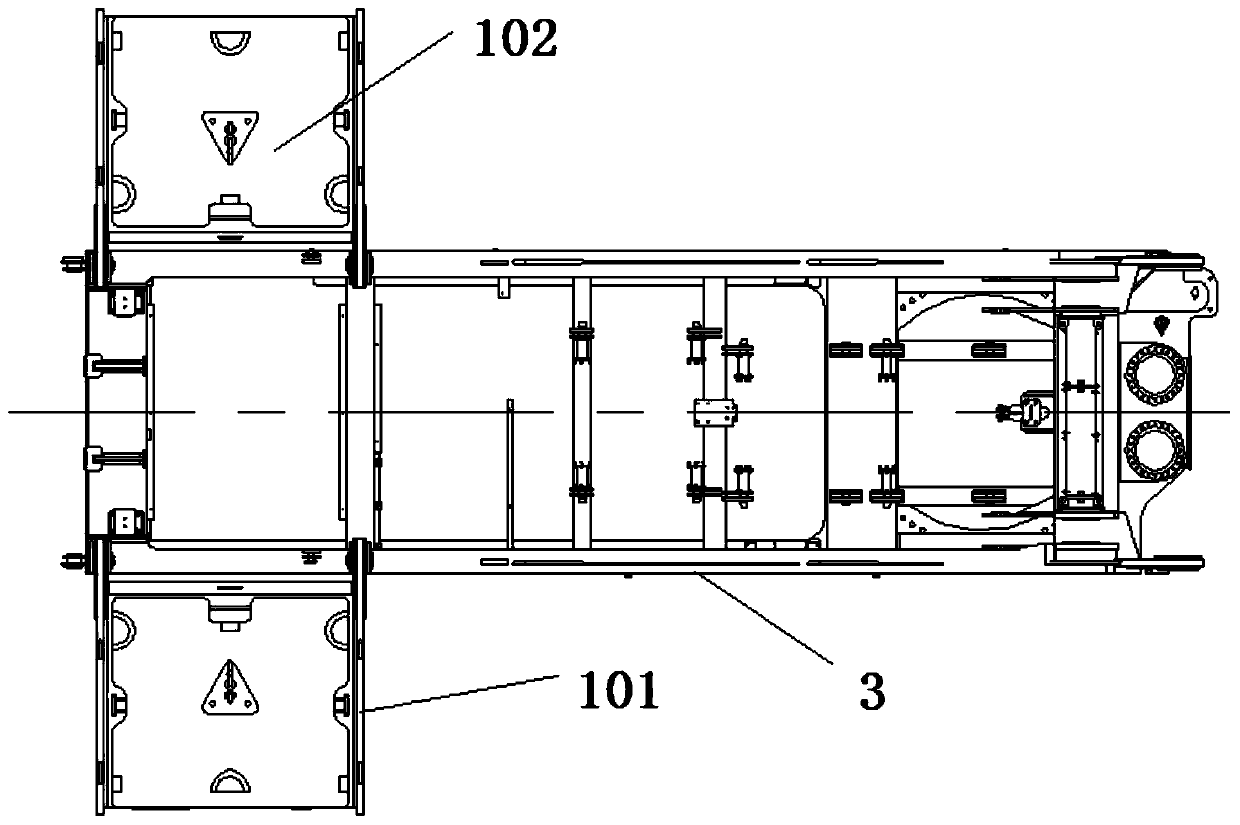

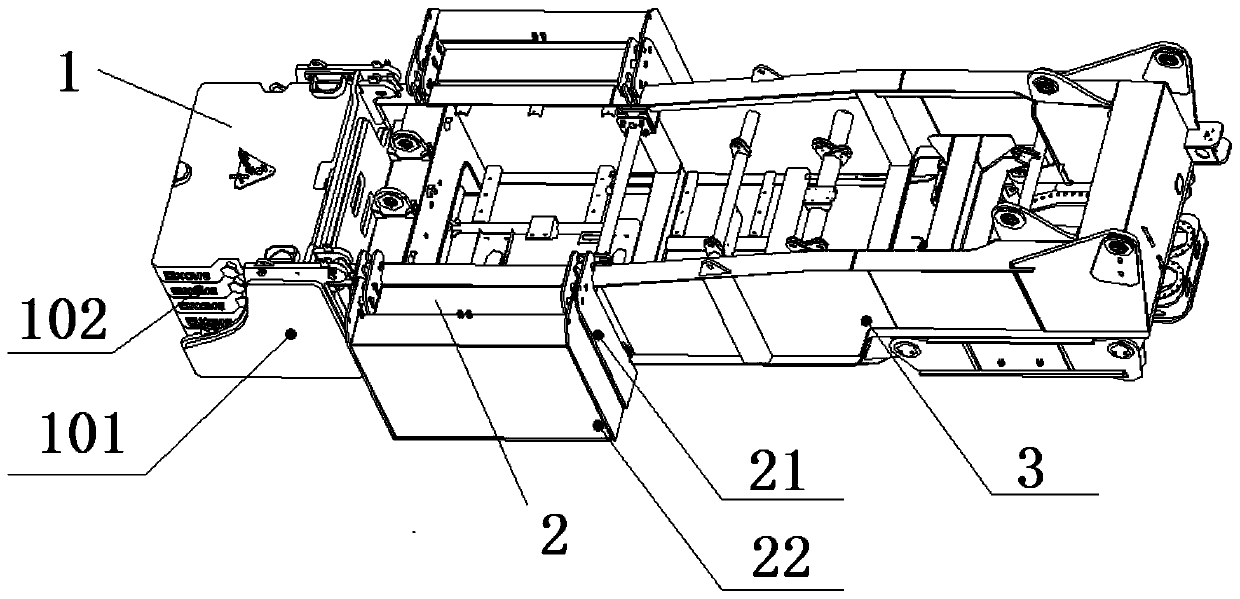

[0023] Such as figure 1 , figure 2 As shown, the balance weight structure in the prior art, the balance weight is placed on the left and right sides of the tail of the turntable 3, and the combination form of the balance weight tray 101+balance weight block 102 is adopted, wherein the balance weight tray 101 is hooked on the left and right sides of the turntable 3 tail. side, level and fasten the counterweight pallet 101, and counterweights 102 are stacked on the counterweight pallet 101 and fastened. The balance weights 102 are fixed in series by chains, the bottom and top of the chains are fixed by baffle plates, and the chains are tightened and fixed by the continuous tightening of long bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com