Anti-skid structure of food processing workshop floor

A technology for food processing and workshops, applied in building construction, covering/lining, construction, etc., can solve the problems of operators falling easily and the ground is slippery, etc., to avoid slipping, increase friction, and avoid deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is further described in detail through specific implementation methods:

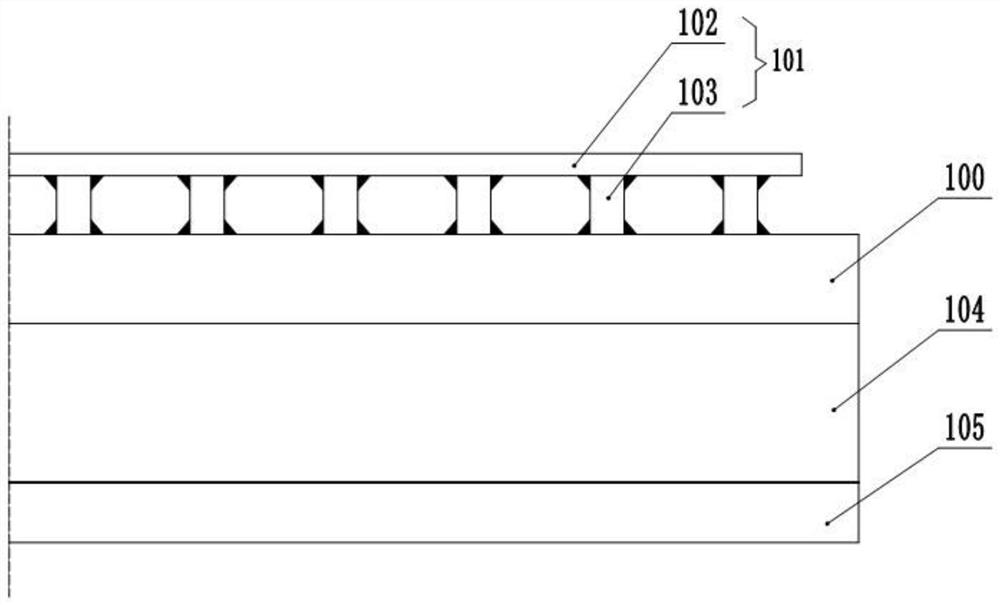

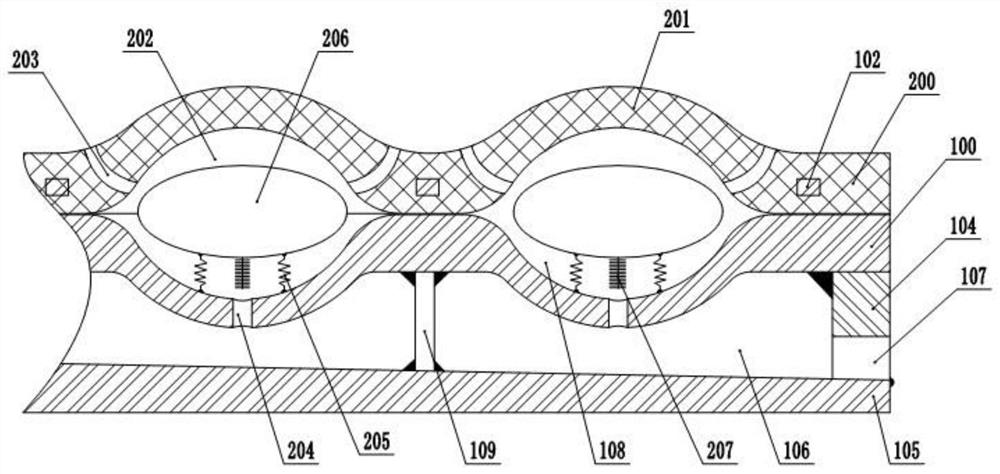

[0031] The reference signs in the drawings of the description include: steel plate layer 100, steel structure frame 101, cross bar 102, support bar 103, support plate 104, positioning plate 105, recycling cavity 106, waste discharge hole 107, groove I 108, reinforcing rib 109. Soft layer 200, convex strip 201, groove II 202, water inlet hole 203, water outlet hole 204, compression spring 205, vibrating ball 206, cleaning brush 207.

[0032] The embodiment is basically as attached figure 1 and figure 2 Shown:

[0033] The floor anti-slip structure of the food processing workshop includes a steel plate layer 100, and a steel skeleton is arranged on the surface of the steel plate layer 100. The steel skeleton includes multiple sets of steel structure frames 101, and the steel structure frame 101 includes cross bars 102 and several support bars 103. One end of 103 is welded on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com