Bimetallic welding plastic coating composite steel pipe

A composite steel pipe and bimetal technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of coating integration, difficult repair, hidden dangers of corrosion resistance of plastic-coated steel pipes, etc., and achieve easy welding , The effect of preventing the decline of anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] In order to make the objectives, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention. Obviously, the described embodiments are part of the implementation of the invention. Examples, not all examples. The embodiments of the present invention are described below in conjunction with the drawings.

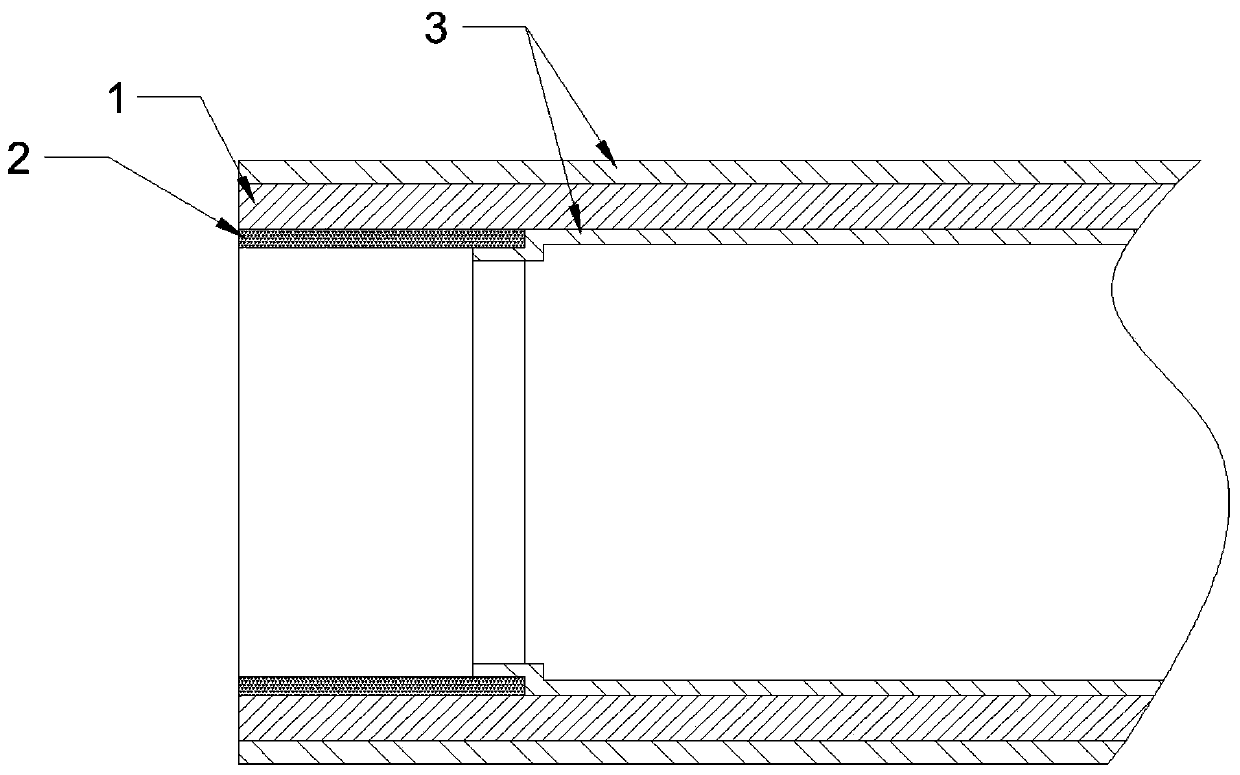

[0016] Such as figure 1 As shown, a bimetal welded plastic-coated composite steel pipe includes a steel pipe base pipe 1. The inner and outer surfaces of the steel pipe base pipe 1 are provided with an anticorrosive coating 3, and the inner side walls of the ports on both sides of the steel pipe base pipe are respectively provided There is a connecting steel plate 2, the connecting steel plate 2 presents a ring shape and is fully covered on the inner side wall of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap