Assembly connection load intelligent control method based on shape memory alloy

A technology of memory alloy and intelligent control, which is applied in the direction of digital control, program control, electrical program control, etc., can solve the problems of affecting production efficiency, increasing equipment maintenance cost, and difficult secondary tightening, so as to reduce maintenance cost and improve equipment Effects of Life Cycle, Enhanced Reliability and Retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

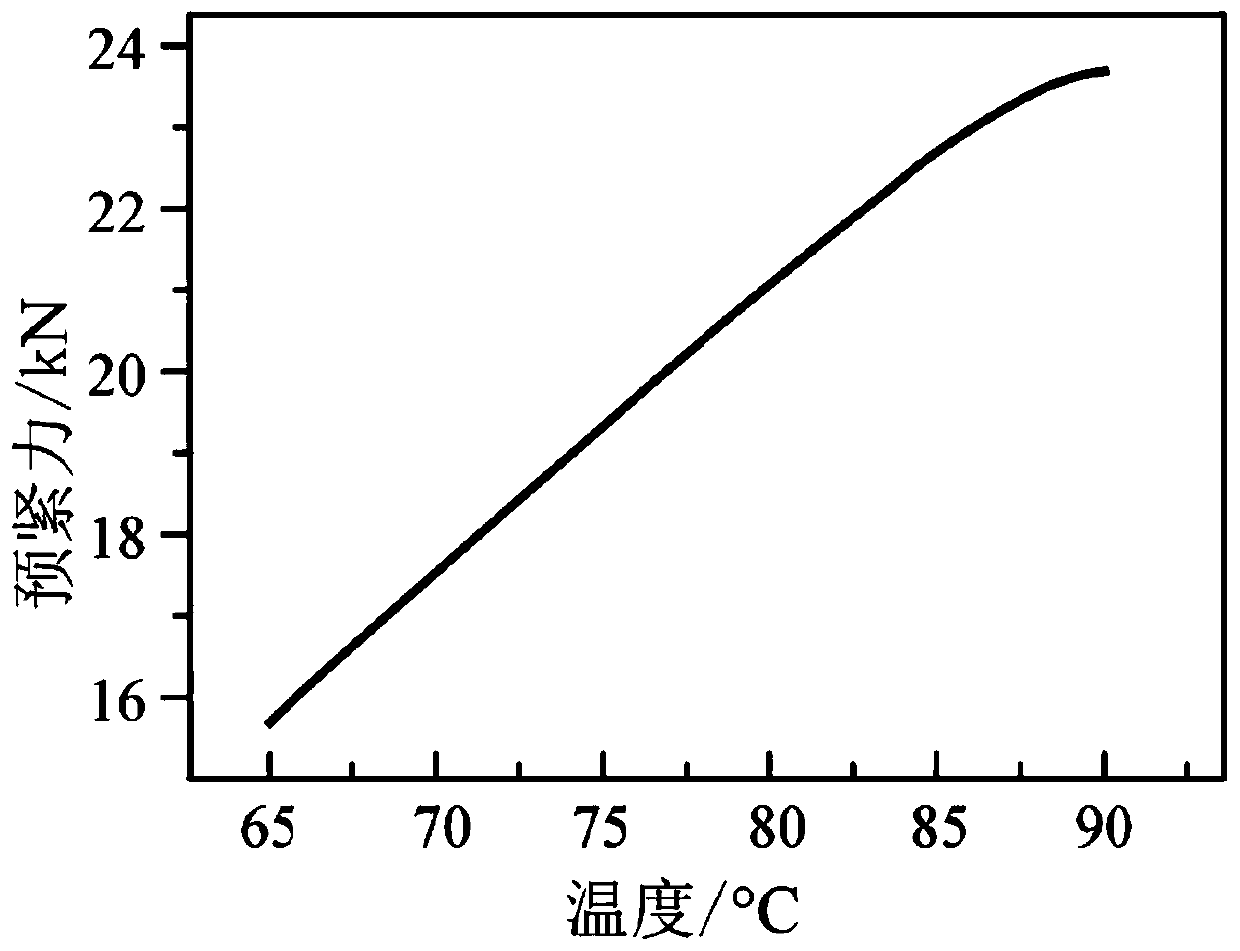

[0129] In this embodiment, M6 single bolt is selected as the test piece, and the load control model of bolted connection using SMA gasket is established. The specific steps are as follows:

[0130] 1) Determination of shape memory alloy material parameters;

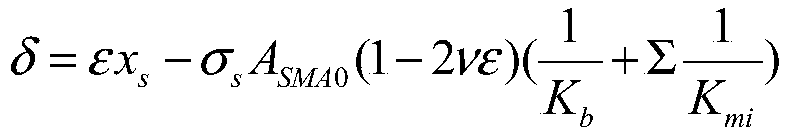

[0131] 2) Establishment of bolt connection deformation coordination equation;

[0132] 3) Calculation of bolt connection stiffness;

[0133] 4) Construction of bolt connection load control model;

[0134] 5) Assembly connection intelligent control.

[0135] Wherein the shape memory alloy material parameter determination comprises the following steps:

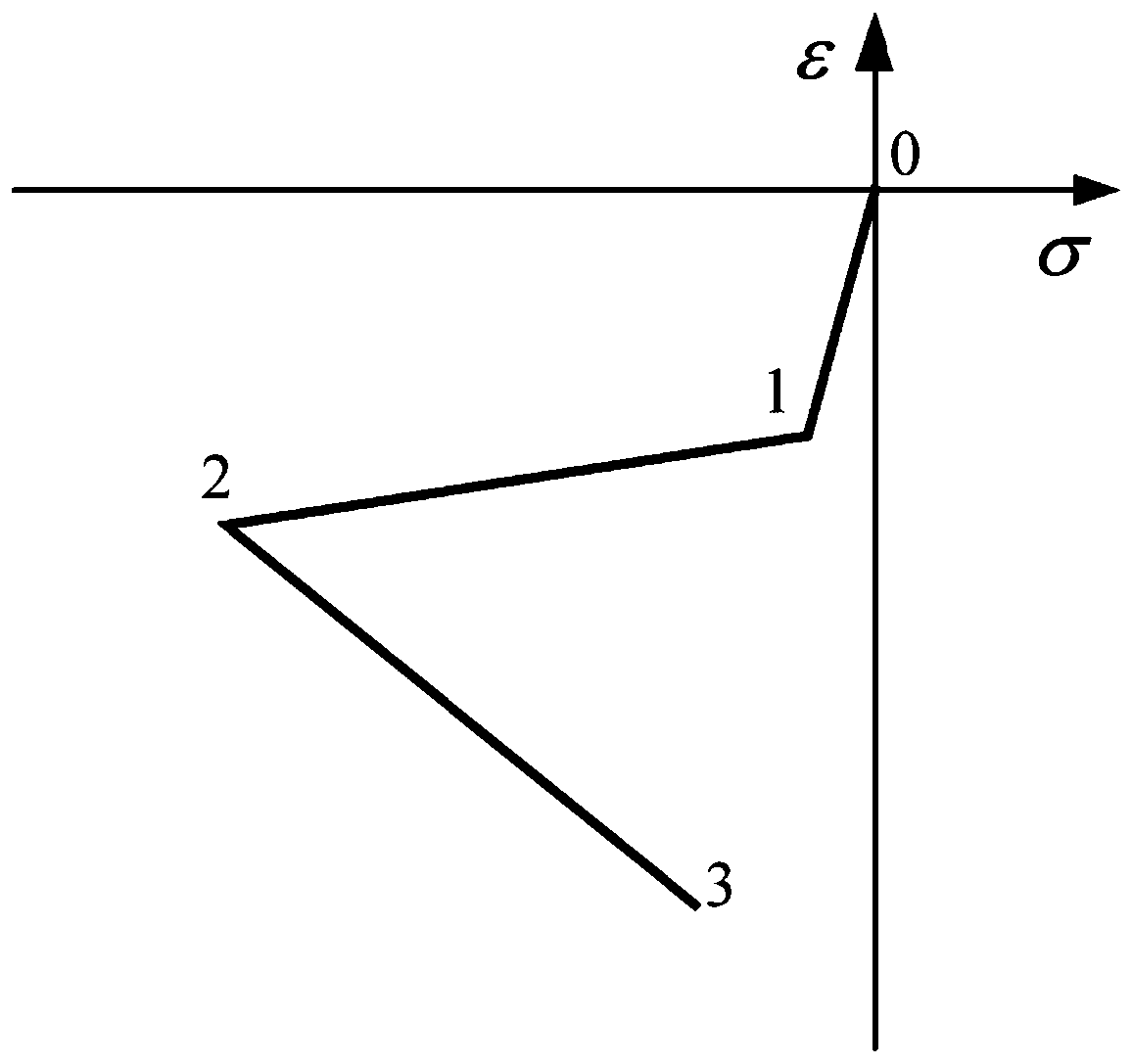

[0136] 1) Determine the required parameters: analyze the classical Tanaka-Liang-Brison shape memory alloy material constitutive model, and determine the performance parameters required to describe the characteristics of the shape memory alloy, including four temperature parameters (A s 、A f , M s , M f ) and seven mechanical properties parameters (E A ,E m , ε L ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com