Corrosion pipeline Bayesian degradation analysis method considering random effect

An analysis method and random effect technology, applied in special data processing applications, instruments, calculations, etc., can solve problems such as complex pipeline operating environment, low precision, and large error in model prediction results, achieving strong flexibility, improving accuracy, Avoid the effect of large forecast errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings:

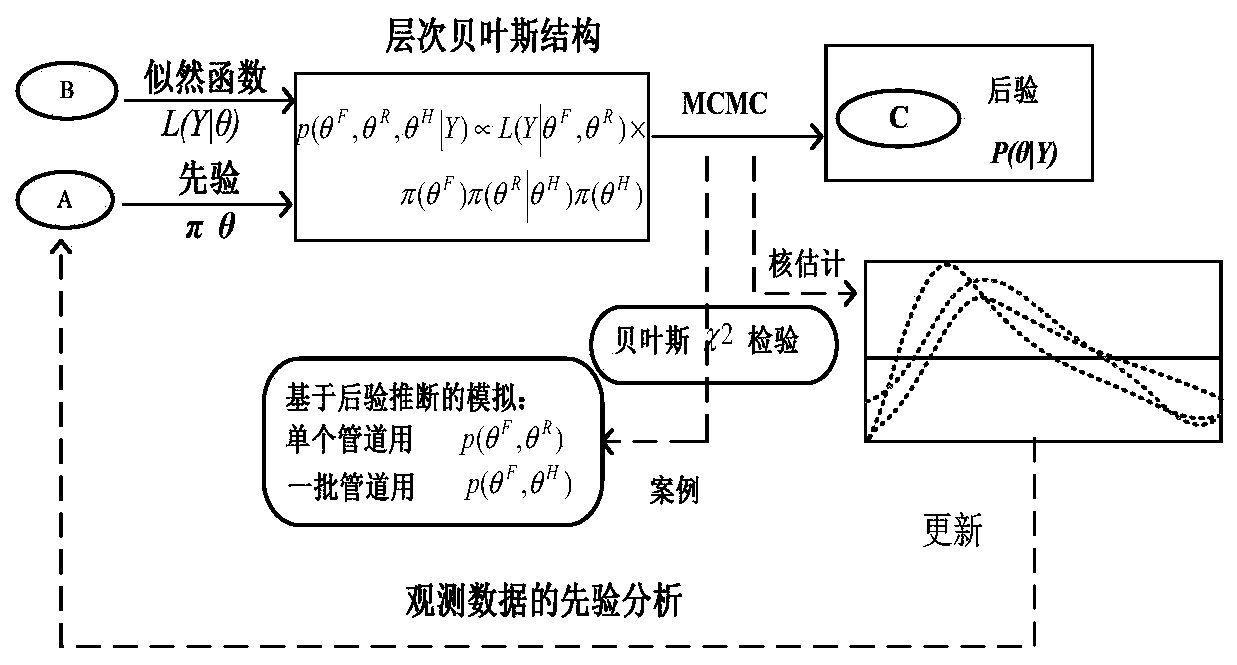

[0038] The Bayesian degradation analysis method of corroded pipelines considering random effects of the present invention includes the following steps:

[0039] 1) Describe the corrosion degradation process of the pipeline through the IG process, and establish a Bayesian analysis framework for model analysis, where the Bayesian analysis framework includes the derivation of the prior distribution, the construction of the likelihood function, the acquisition of the posterior distribution, and Analysis process;

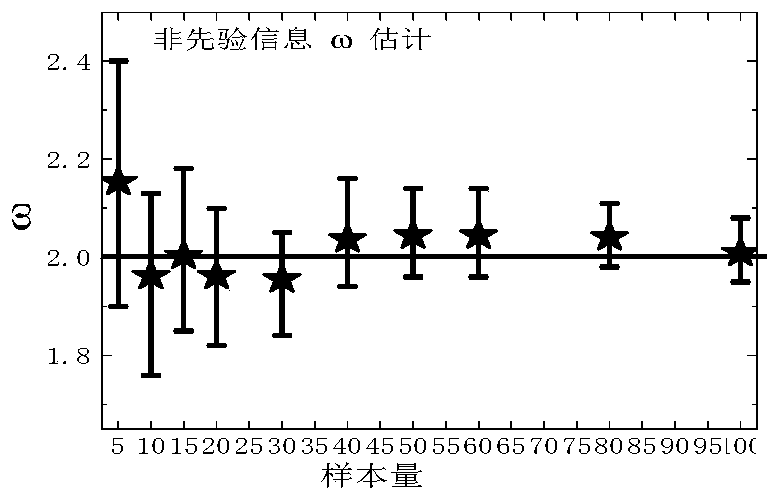

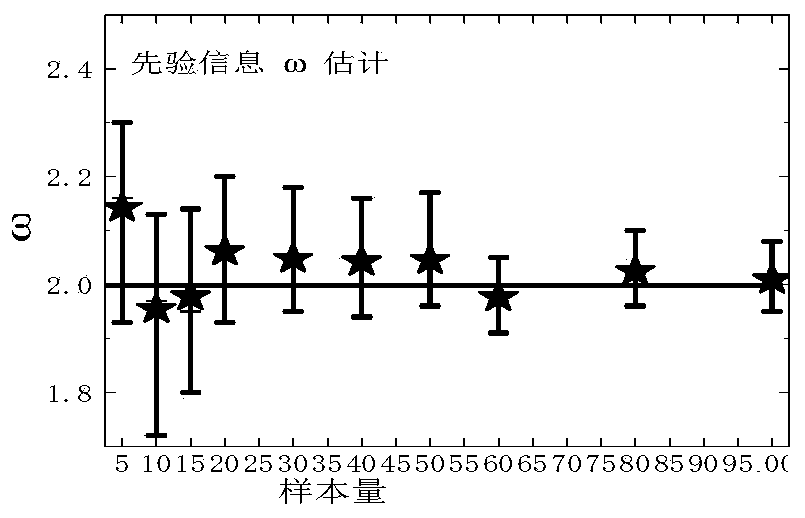

[0040] 2) Analyze the inverse Gaussian process model, random drift inverse Gaussian model, random fluctuation inverse Gaussian model, and random drift-fluctuation inverse Gaussian model respectively by using Bayesian method;

[0041] The likelihood function of degenerate data under the inverse Gaussian process model is Get t m+1 Reliability function at time T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com