Method for producing a blank for a packaging item, blank and packaging made from a blank

A technology of blanks and articles, applied in the field of blanks for the production of packaging articles, which can solve problems such as difficulty in adapting to substrates or packaging variants, and achieve the effect of preventing the formation of broken or deformed edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

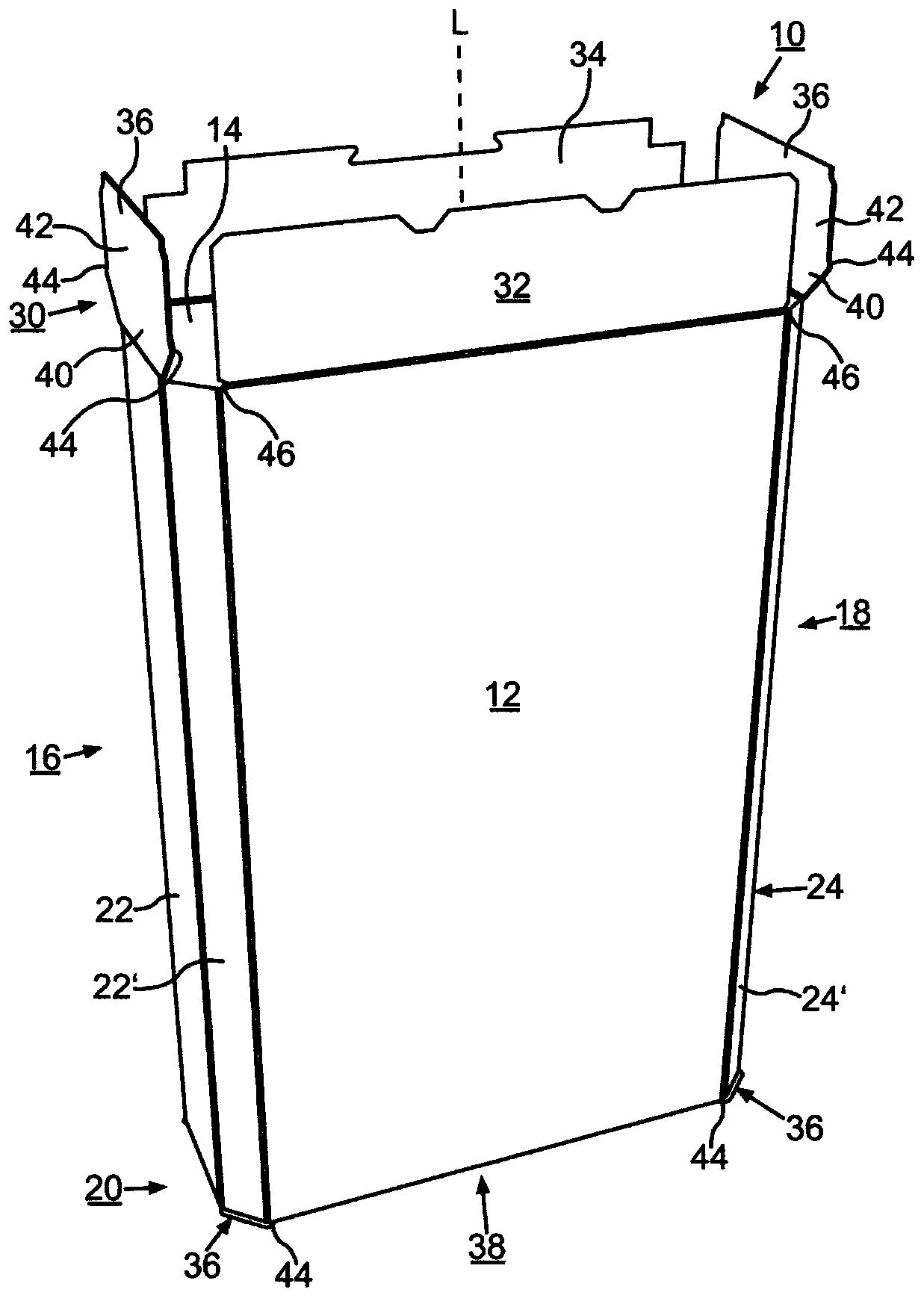

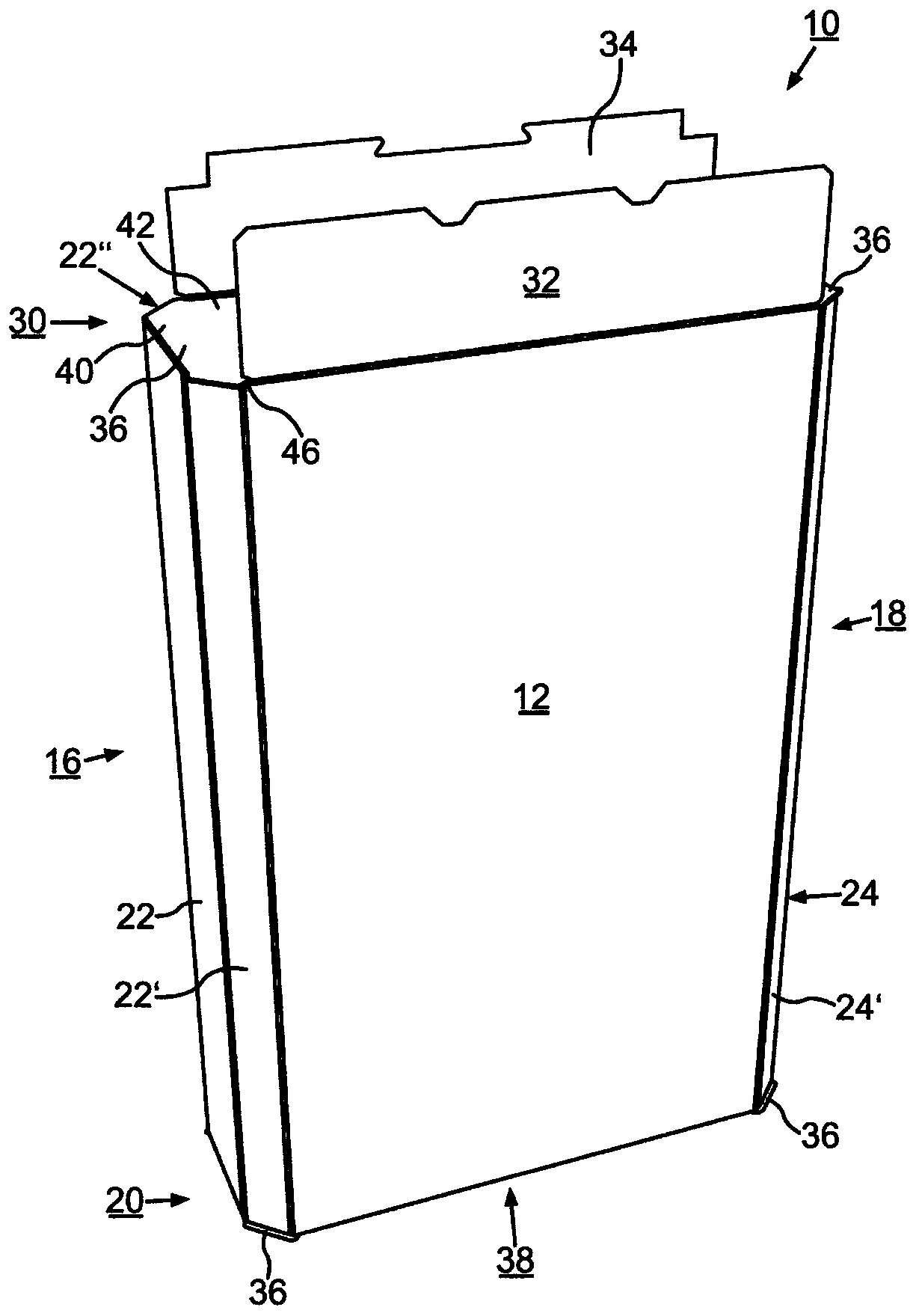

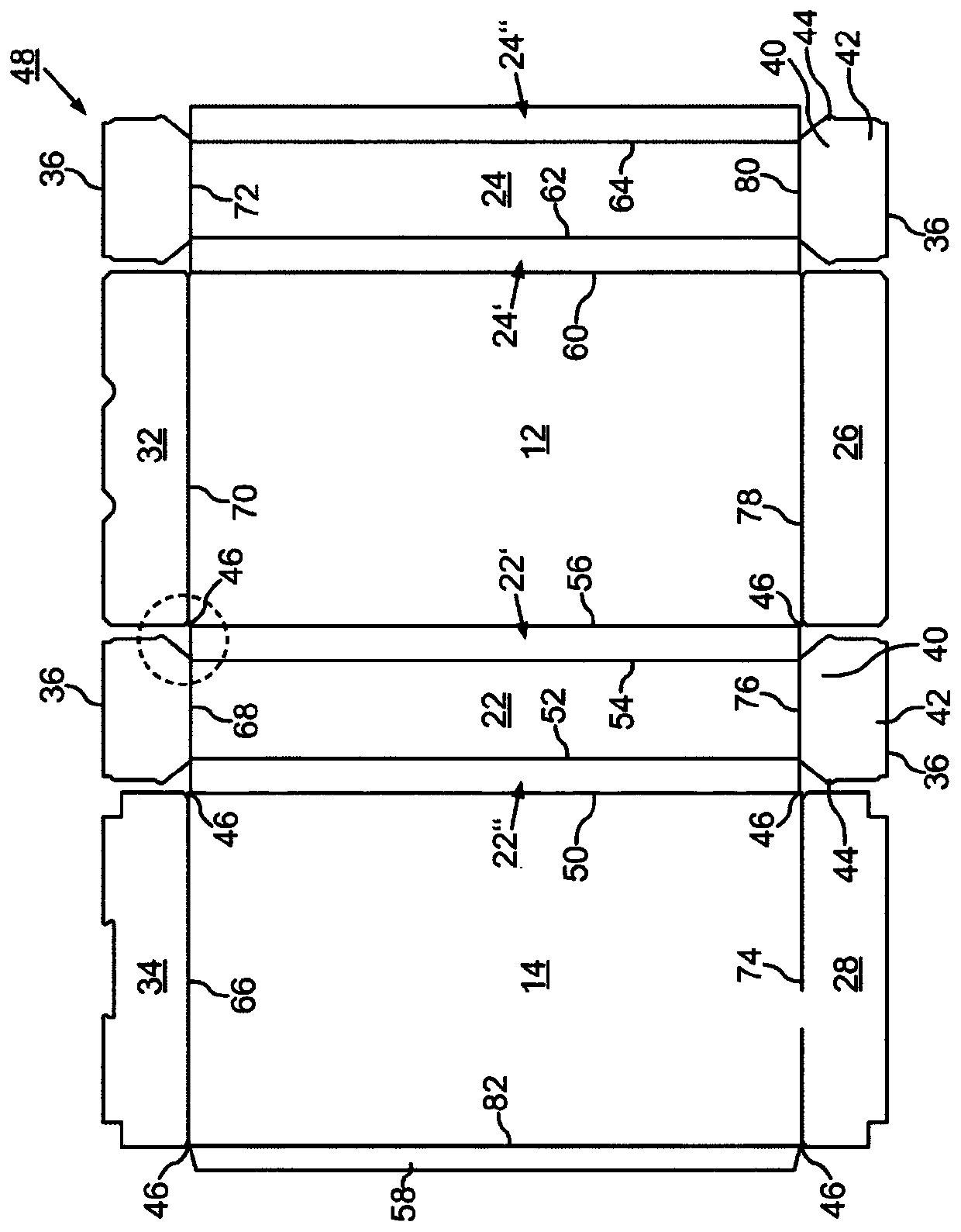

[0034] figure 1 A schematic view is shown of a packaging item 10 according to the invention, particularly for storing and transporting pourable, powdered and free-flowing food products, such as cereals. The packaged article 10 is constructed of cardboard and includes a front wall 12 and a rear wall 14 connected by three side walls 22, 22', 22", 24, 24', 24", respectively (see figure 2 and image 3 ). The side walls 22 , 22 ′, 22 ″, 24 , 24 ′, 24 ″ form the end sides 16 , 18 of the packaged article 10 . It is recognized that the packaging item 10 is formed in the shape of a prism along the longitudinal axis L and has an octagonal base 38 . In addition, the packaged article 10 includes a bottom structure 20 including bottom flaps 26, 28 each hinged to the front wall 12 and rear wall 14 for closing the bottom side of the packaged article 10 (see also image 3 ). Furthermore, packaged item 10 includes a lid structure 30 , wherein lid structure 30 includes each cover flap 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com