Safety cap spout providing accuracy of opening and easiness of check

A convenient and safe cover technology, applied in the direction of capping, safety devices, closures, etc., can solve the problems of decreased support force, poor assembly line of injection molding products, and high defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

[0050] first Figure 1 to Figure 9 is the shape of the spout of the safety cap according to the first embodiment of the present invention.

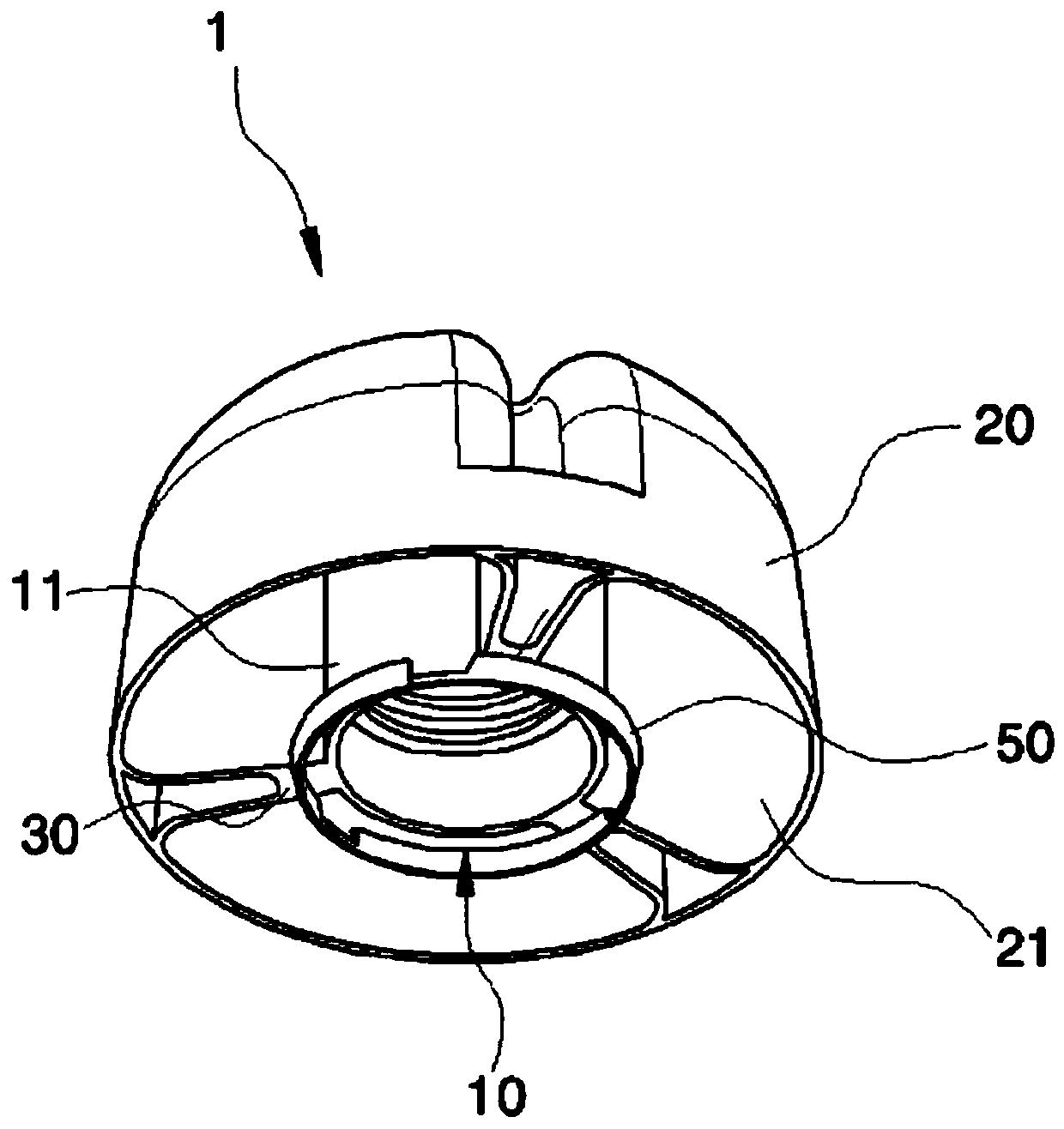

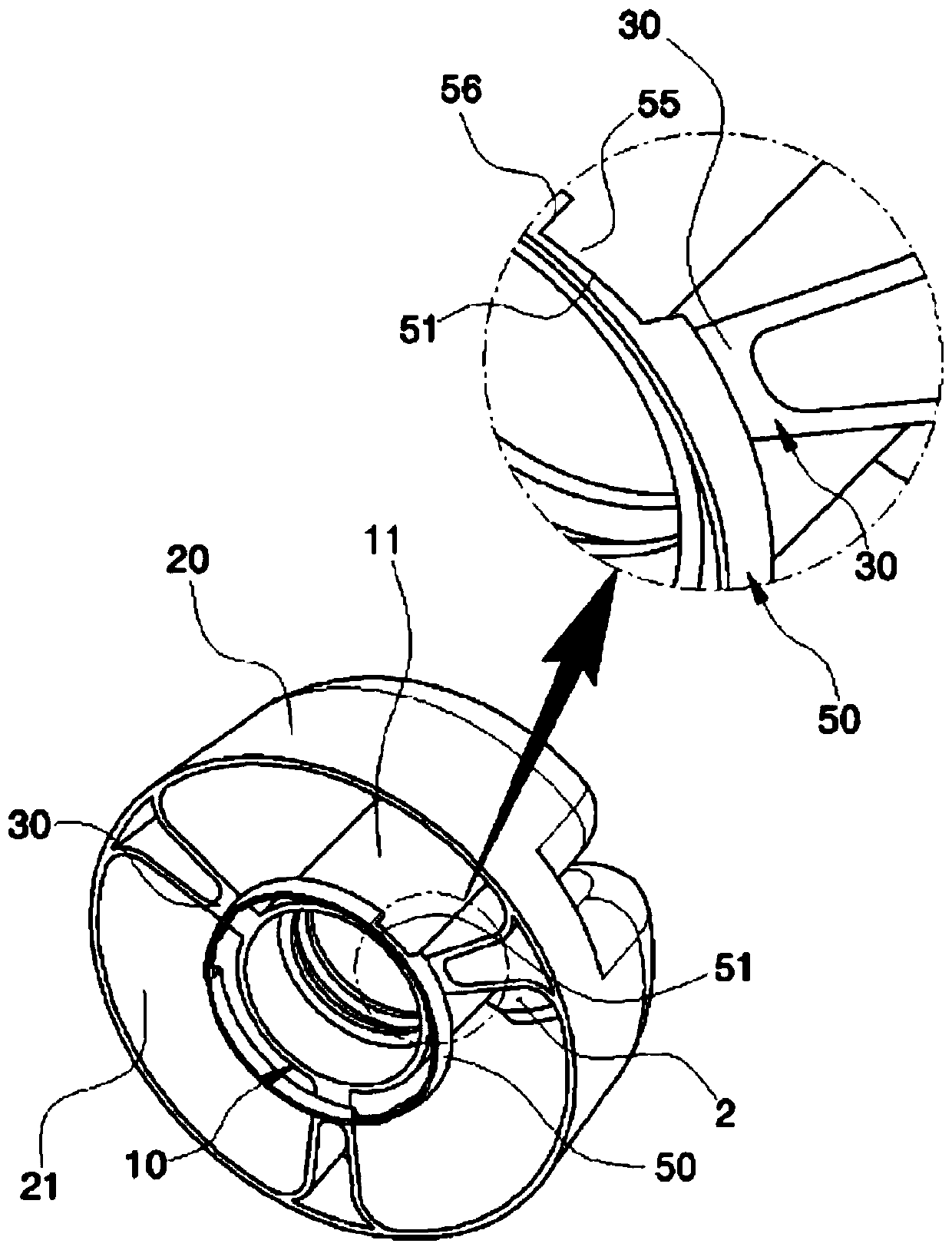

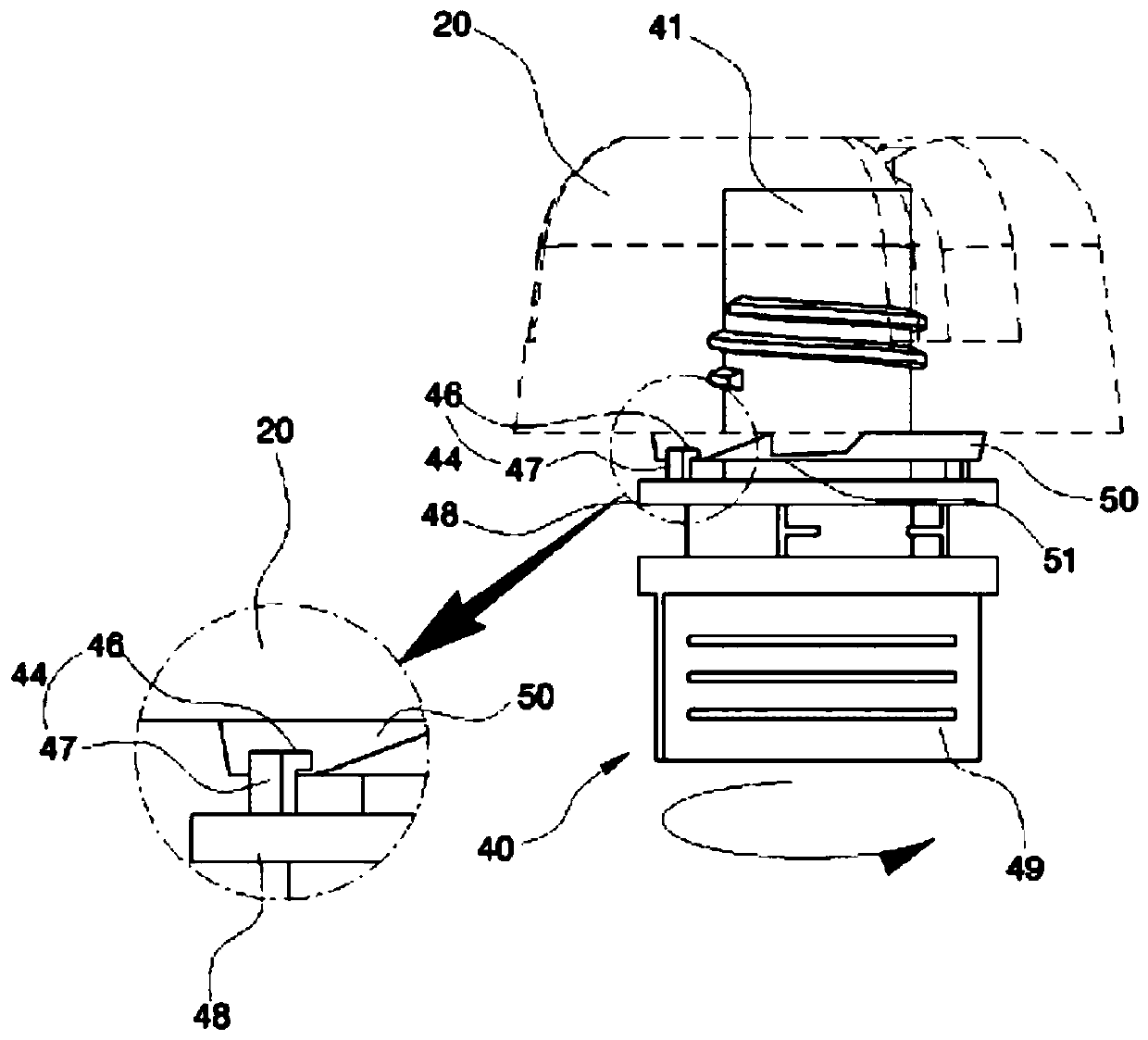

[0051] attached figure 1 It is a closure 1 of a fruit juice, various beverages, etc., especially a liquid bag container 100 for children, which is preferably a plastic injection-molded closure that is welded on the mouth 41 of the main body 40 of the bag container 100 through threads Way to tighten and unscrew.

[0052] The cover 1 comprises, an inner cover 10 arranged along the central axis X and configured as a tubular body; an outer cover 20 connected with the outer wall of the inner cover 10 to the inner wall of the annular wall portion 21 through a cock 30; a vent hole 2. Since there are more than two cocks 30, a vent hole 2 is formed between the cocks.

[0053] That is to say, the annular wall portion 21 is spaced a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com