Celery processing slicer

A vegetable cutter, celery technology, applied in metal processing and other directions, can solve the problems of cuts, slow cutting speed, troublesome operation, etc., and achieve the effect of preventing movement, avoiding jamming, and avoiding cuts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

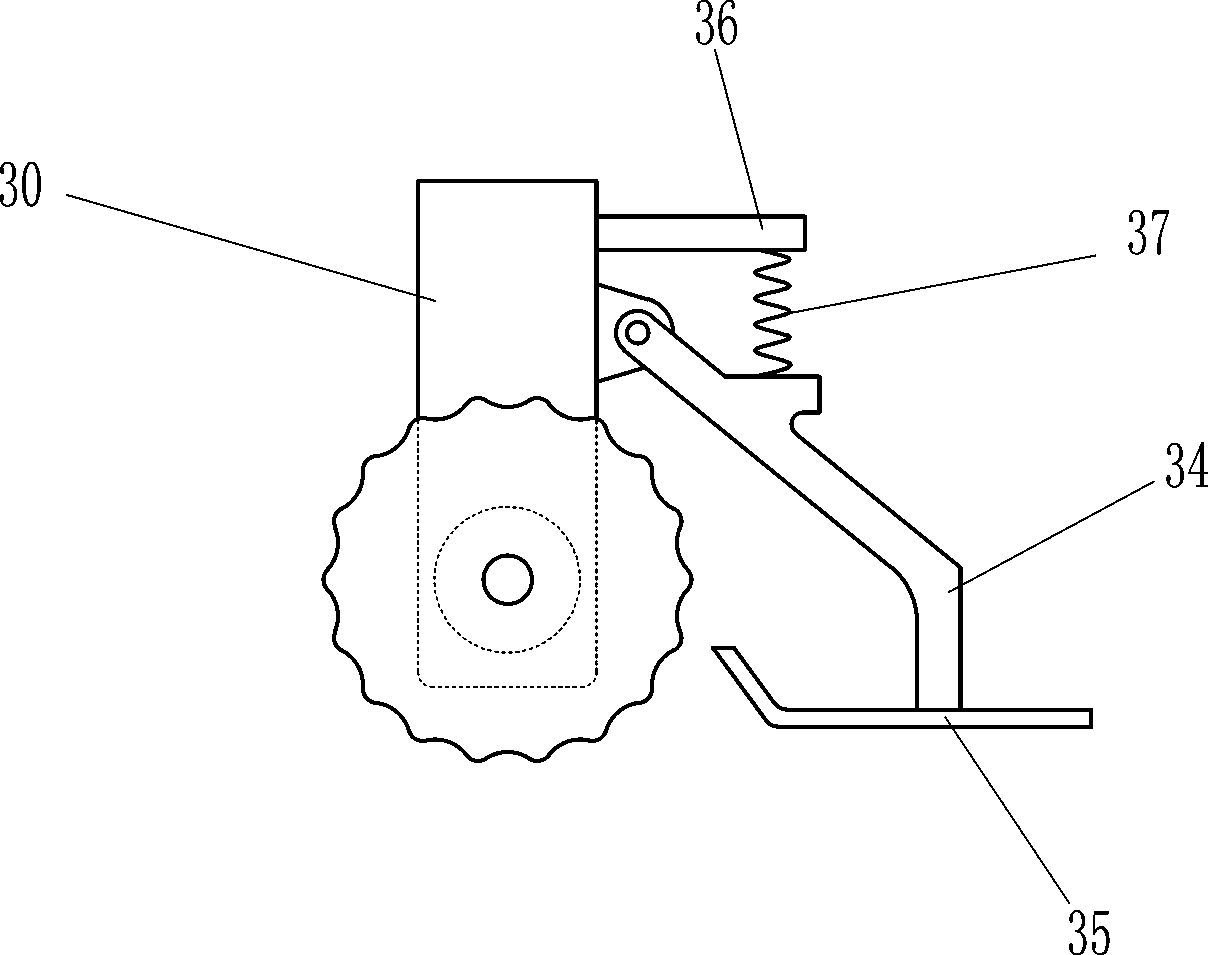

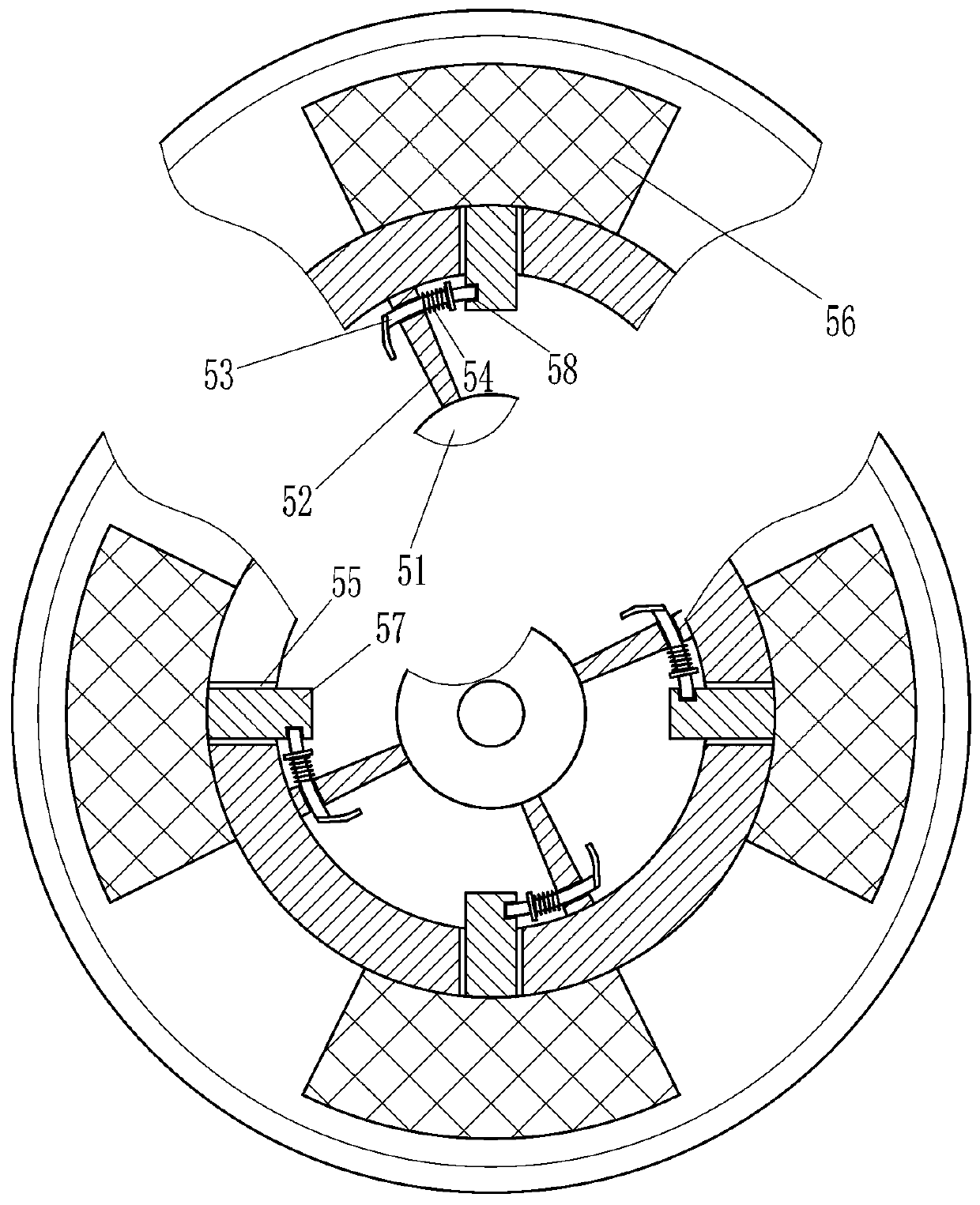

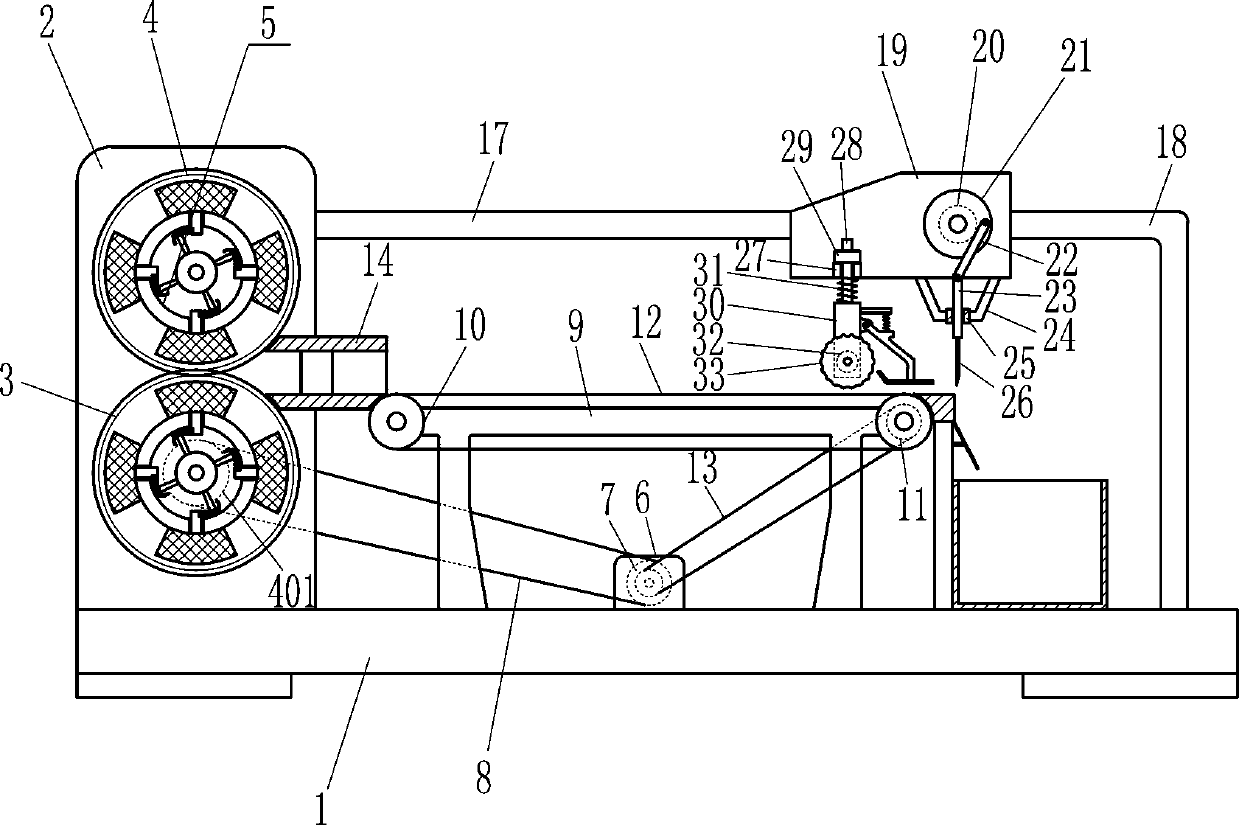

[0023] A celery making vegetable cutter such as Figure 1-5As shown, it includes a base 1, a first mounting plate 2, a first gear 3, a second gear 4, a first pulley 401, a pressing wheel mechanism 5, a first motor 6, a double-groove pulley 7, and a first belt 8. Mounting frame 9, roller 10, second pulley 11, conveyor belt 12, second belt 13, clamping plate 14, mounting block 15, blade 16, straight connecting plate 17, L connecting plate 18, second mounting plate 19 , the second motor 20, the turntable 21, the first connecting rod 22, the second connecting rod 23, the bracket 24, the first sliding sleeve 25 and the cutter 26, the mounting frame 9 is fixedly connected to the top of the base 1, and the two supporting rollers 10 Respectively rotatably installed on the left and right ends of the mounting bracket 9, a conveyor belt 12 that can transport celery is wound around the left and right side rollers 10, and the second belt pulley 11 is installed at the center of the circle o...

Embodiment 2

[0025] A celery making vegetable cutter such as Figure 1-5 As shown, it includes a base 1, a first mounting plate 2, a first gear 3, a second gear 4, a first pulley 401, a pressing wheel mechanism 5, a first motor 6, a double-groove pulley 7, and a first belt 8. Mounting frame 9, roller 10, second pulley 11, conveyor belt 12, second belt 13, clamping plate 14, mounting block 15, blade 16, straight connecting plate 17, L connecting plate 18, second mounting plate 19 , the second motor 20, the turntable 21, the first connecting rod 22, the second connecting rod 23, the bracket 24, the first sliding sleeve 25 and the cutter 26, the mounting frame 9 is fixedly connected to the top of the base 1, and the two supporting rollers 10 Respectively rotatably installed on the left and right ends of the mounting bracket 9, a conveyor belt 12 that can transport celery is wound around the left and right side rollers 10, and the second belt pulley 11 is installed at the center of the circle ...

Embodiment 3

[0028] A celery making vegetable cutter such as Figure 1-5 As shown, it includes a base 1, a first mounting plate 2, a first gear 3, a second gear 4, a first pulley 401, a pressing wheel mechanism 5, a first motor 6, a double-groove pulley 7, and a first belt 8. Mounting frame 9, roller 10, second pulley 11, conveyor belt 12, second belt 13, clamping plate 14, mounting block 15, blade 16, straight connecting plate 17, L connecting plate 18, second mounting plate 19 , the second motor 20, the turntable 21, the first connecting rod 22, the second connecting rod 23, the bracket 24, the first sliding sleeve 25 and the cutter 26, the mounting frame 9 is fixedly connected to the top of the base 1, and the two supporting rollers 10 Respectively rotatably installed on the left and right ends of the mounting bracket 9, a conveyor belt 12 that can transport celery is wound around the left and right side rollers 10, and the second belt pulley 11 is installed at the center of the circle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com