A cashmere scrap recovery compressor

A technology of leftover materials and compressors, applied in the field of compressors, which can solve the problems of easy warping of the edge of the pressure plate, troublesome binding, loose leftover materials, etc., and achieve the effects of stable air pressure, stable and uniform compression, and small pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

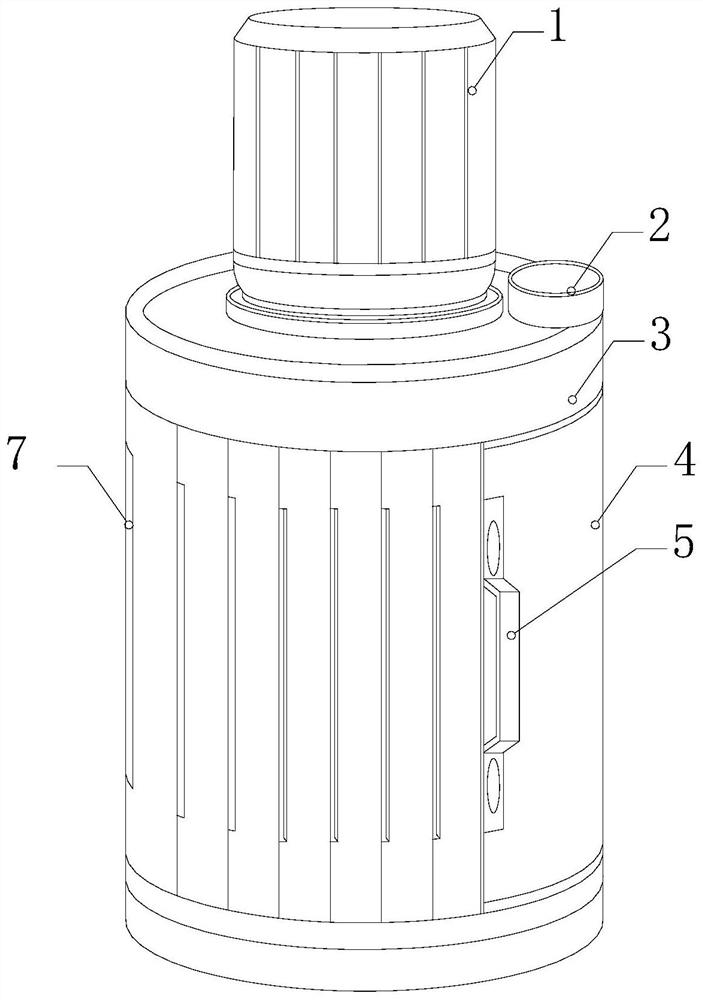

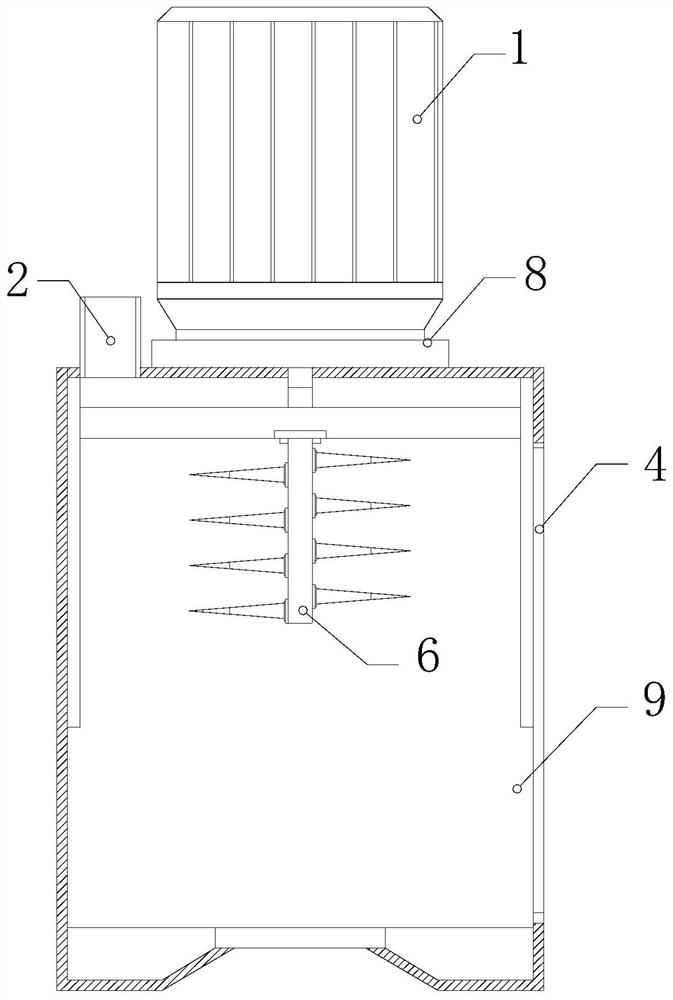

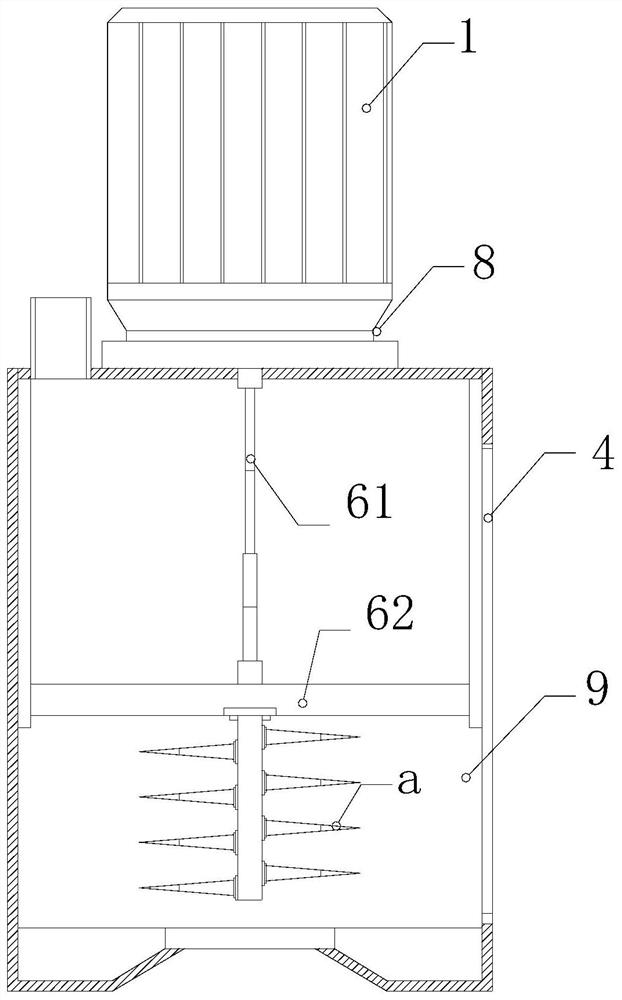

[0023] see Figure 1-Figure 5 , the present invention provides a cashmere leftover recycling compressor, the structure of which includes a motor 1, an air outlet 2, a cylinder body 3, an opening and closing door 4, a handle 5, a down-rotating compression structure 6, an exhaust port 7, a motor base 8, an inner Cavity 9, a motor base 8 is provided in the middle of the top surface of the cylinder body 3, a motor base 8 is vertically welded in the middle of the top surface of the cylinder body 3, a motor 1 is placed on the motor base 8, and the motor 1 outputs After the axis vertically penetrates the cylinder 3, it engages with the down-rotating compression structure 6 inside the cylinder 3. The outer surface of the cylinder 3 is provided with an opening and closing door 4, and a handle 5 is installed on the opening and closing door 4. The opening and closing The outer surface of the cylinder body 3 on both sides of the door 4 is provided with more than two exhaust ports 7 on ave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com