Cup type tower

A wine glass and tower head technology, which is applied in the field of wine glass towers, can solve the problems of increased floor area of wine glass towers, easy occurrence of wind deflection flashover, wire swing, etc., and achieves the effects of saving floor space, high mechanical strength, and compressed width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

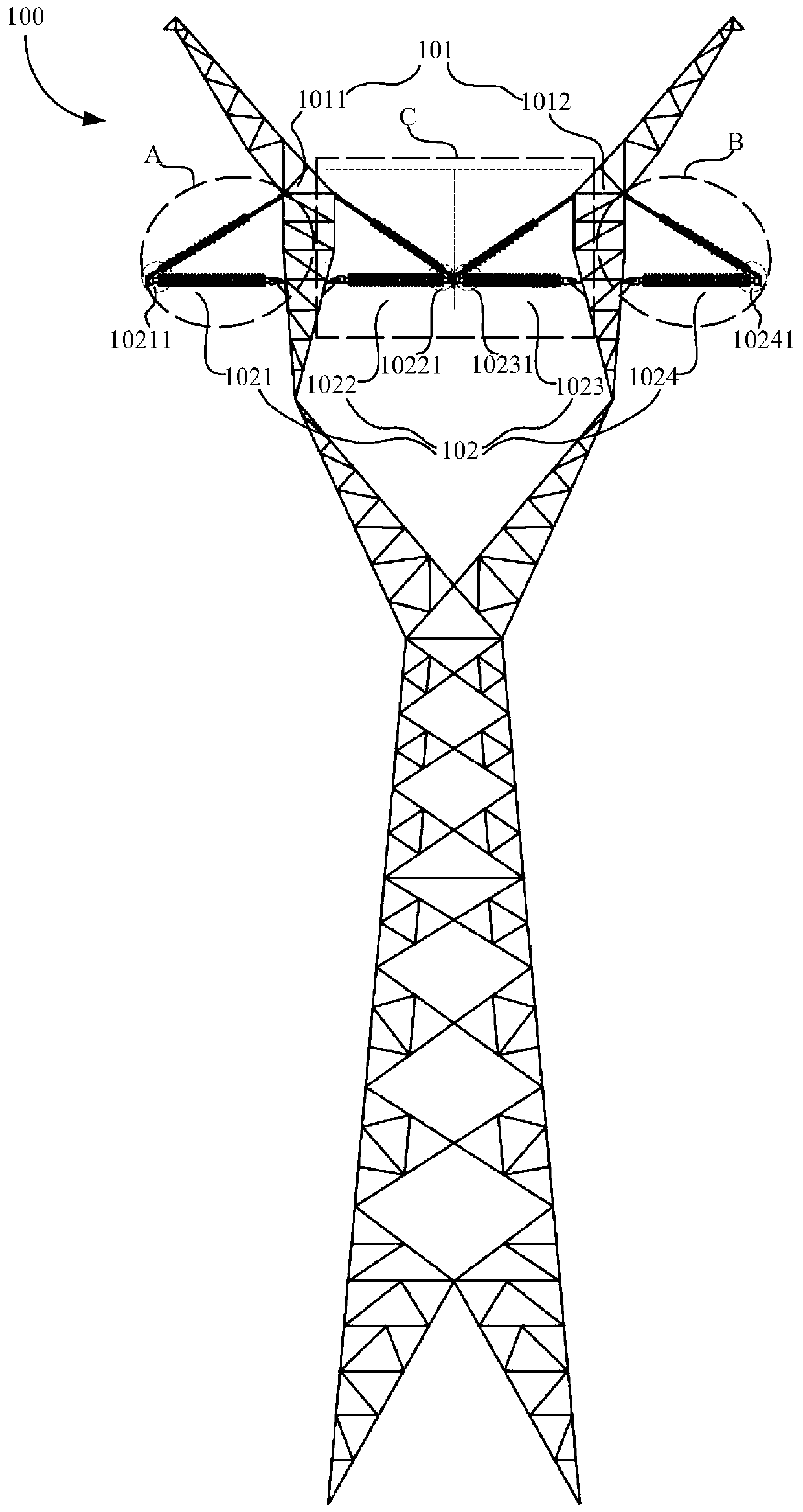

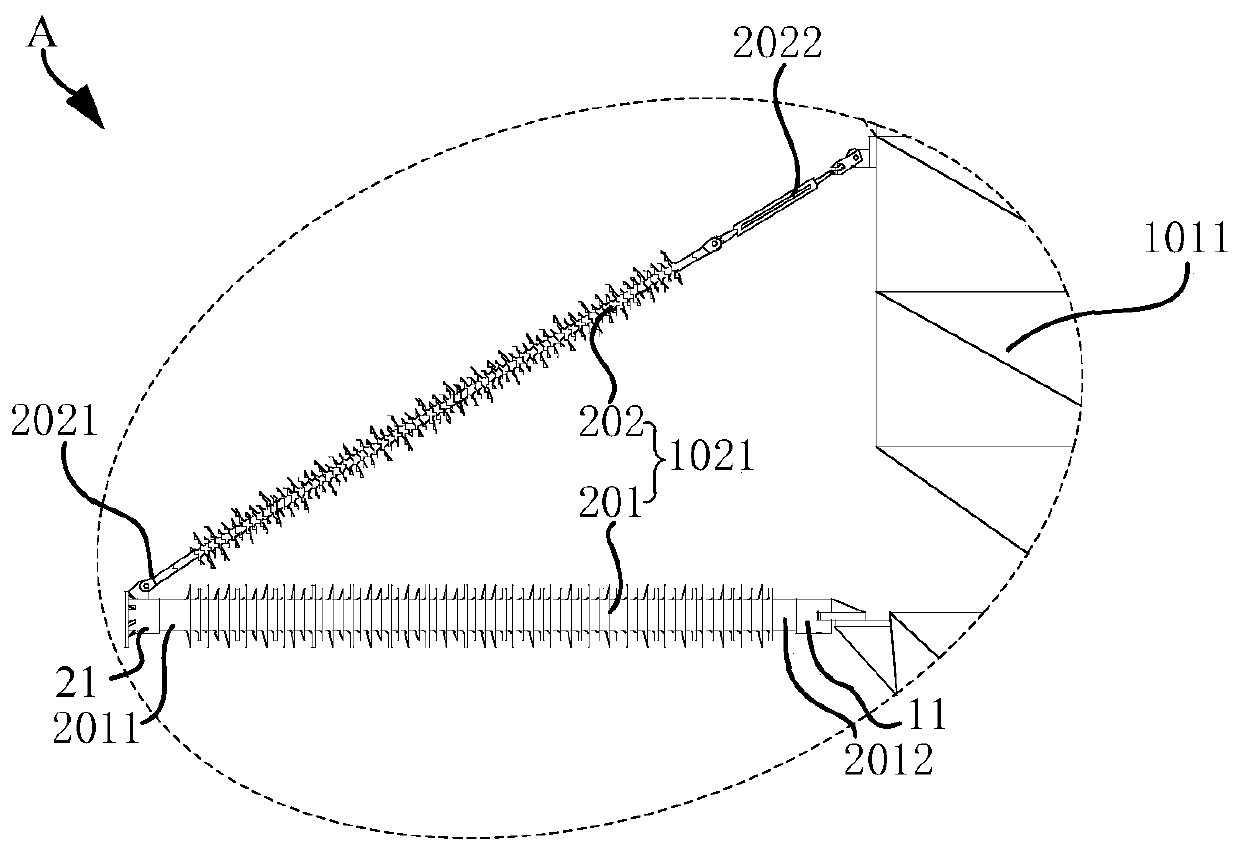

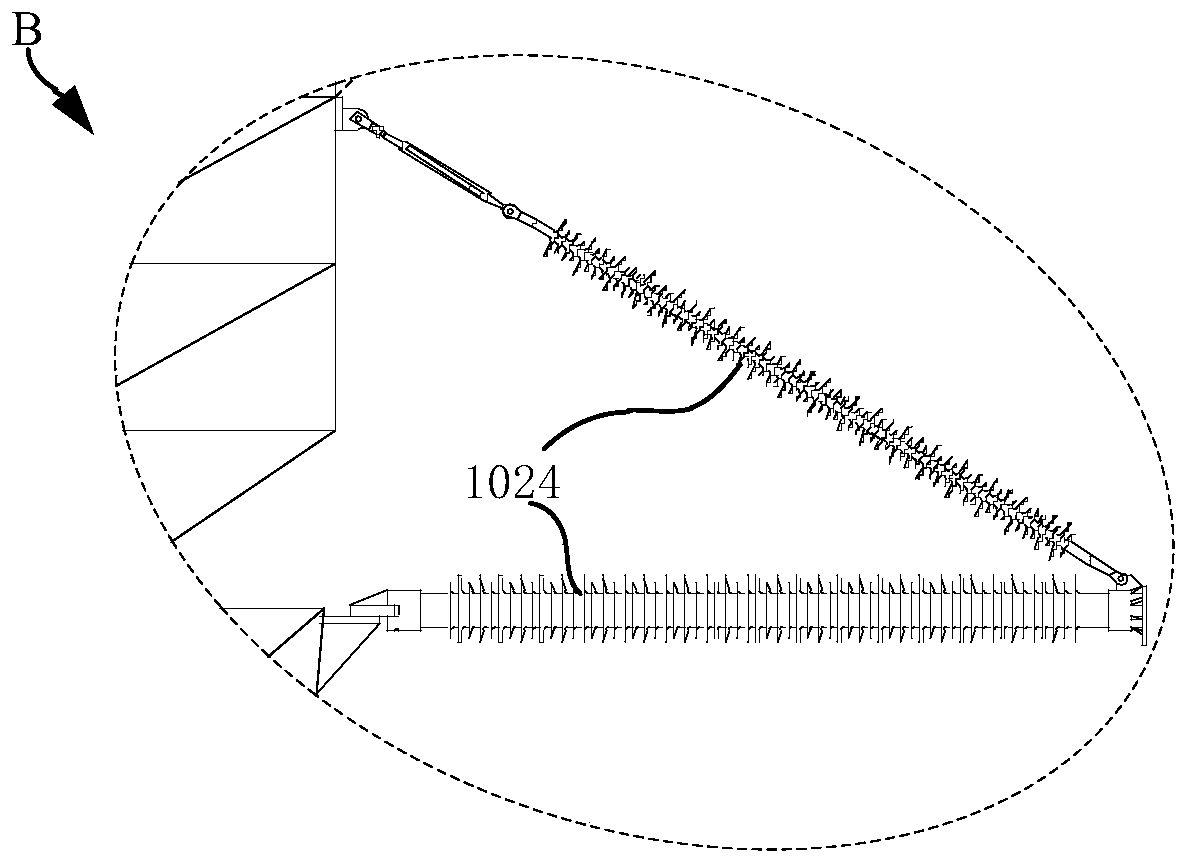

[0031] see figure 1 , figure 1 It is a structural schematic diagram of an embodiment of the wineglass tower 100 of the present application. Specifically, the wineglass tower 100 may include a tower head 101 and several sets of composite cross arms 102. In an implementation scenario, the wineglass tower 100 may be provided with two tower arms for the convenience of connecting three-phase conductors, namely figure 1 The tower arm 1011 and the tower arm 1012 are arranged symmetrically in the center. In several groups of composite cross arms 102, at least one end of each group of composite cross arms 102 is connected to the tower head 101, for example, as figure 1 As shown, several groups of composite cross-arms 102 are specifically four groups, including composite cross-arm 1021 , composite cross-arm 1022 , composite cross-arm 1023 , and composite cross-arm 1024 . One end of the composite cross arm 1021 , the composite cross arm 1022 , the composite cross arm 1023 , and the co...

Embodiment 2

[0038] In the implementation manner mentioned in the first embodiment above, as figure 1 As shown, due to the large distance between the tower arm 1011 and the tower arm 1012, generally, it is necessary to adopt the following figure 1 The middle composite cross-arm 1022 and the composite cross-arm 1023 are connected to each other, so as to realize the connection of the middle-phase conductor. In specific implementation, such as Figure 6 As shown, there may also be a small distance between the two tower arms 1111 and the tower arm 1112 in the tower head 1110, so that the connection with the tower arm 1111 and the tower arm 1112 can be realized by using a group of composite cross arms 1122 in the C area . For details, please refer to Figure 6 A structural schematic diagram of another embodiment of the wineglass tower 110 is shown.

[0039] Besides that, with figure 1 Similar to the wineglass tower 100 shown, Figure 6 The wine glass tower 110 in the above is provided wit...

Embodiment 3

[0046] see Figure 8 , Figure 8 It is a structural schematic diagram of an embodiment of the wineglass tower 130 of the present application. and figure 1 The Blackjack Tower 100 shown differs in that Figure 8 Several groups of composite cross-arms 1320 of the wineglass tower 130 do not include composite cable-stayed cross-arms.

[0047] Besides that, with figure 1 The Blackjack Tower 100 in the similar, Figure 8 The wineglass tower 130 in includes a tower head 1310. In an implementation scenario, in order to facilitate the connection of three-phase wires, the wineglass tower 130 can be provided with two tower arms, namely Figure 8 The tower arm 1311 and the tower arm 1312 are arranged symmetrically in the center. In several groups of composite cross arms 1320, at least one end of each group of composite cross arms 1320 is connected to tower head 1310, for example, as Figure 8 As shown, several sets of composite cross-arms 1320 include four sets of composite cross-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com