Differential pressure mine automatic fire extinguisher based on novel extinguishant

A fire extinguishing agent, differential pressure technology, applied in mining equipment, fire prevention, safety devices, etc., can solve the problems of workers' life danger, high delay, serious and other problems, and achieve the effect of good fire extinguishing effect, good effect and wide area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

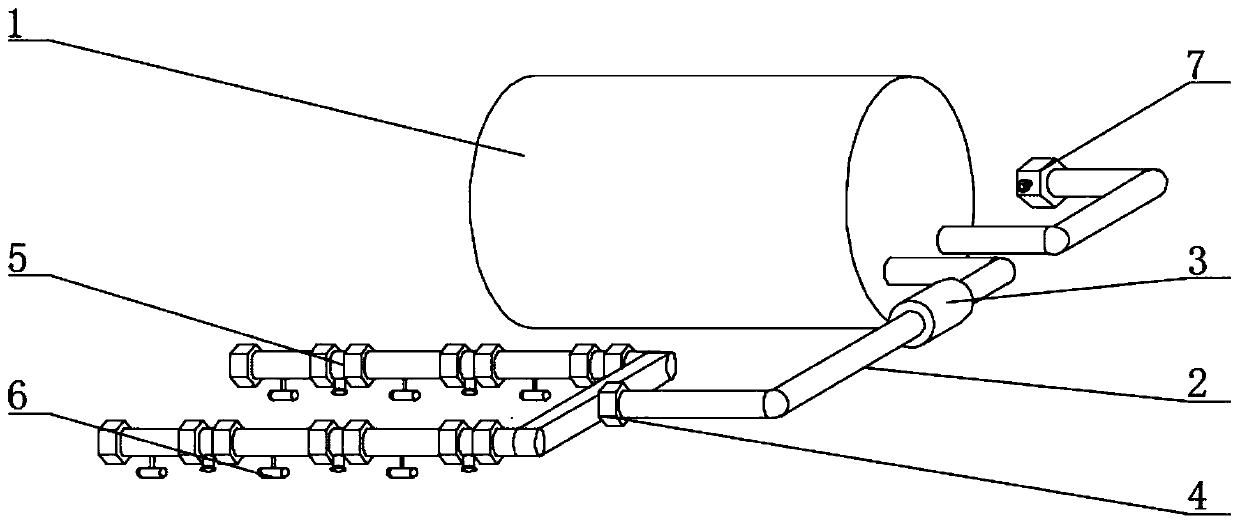

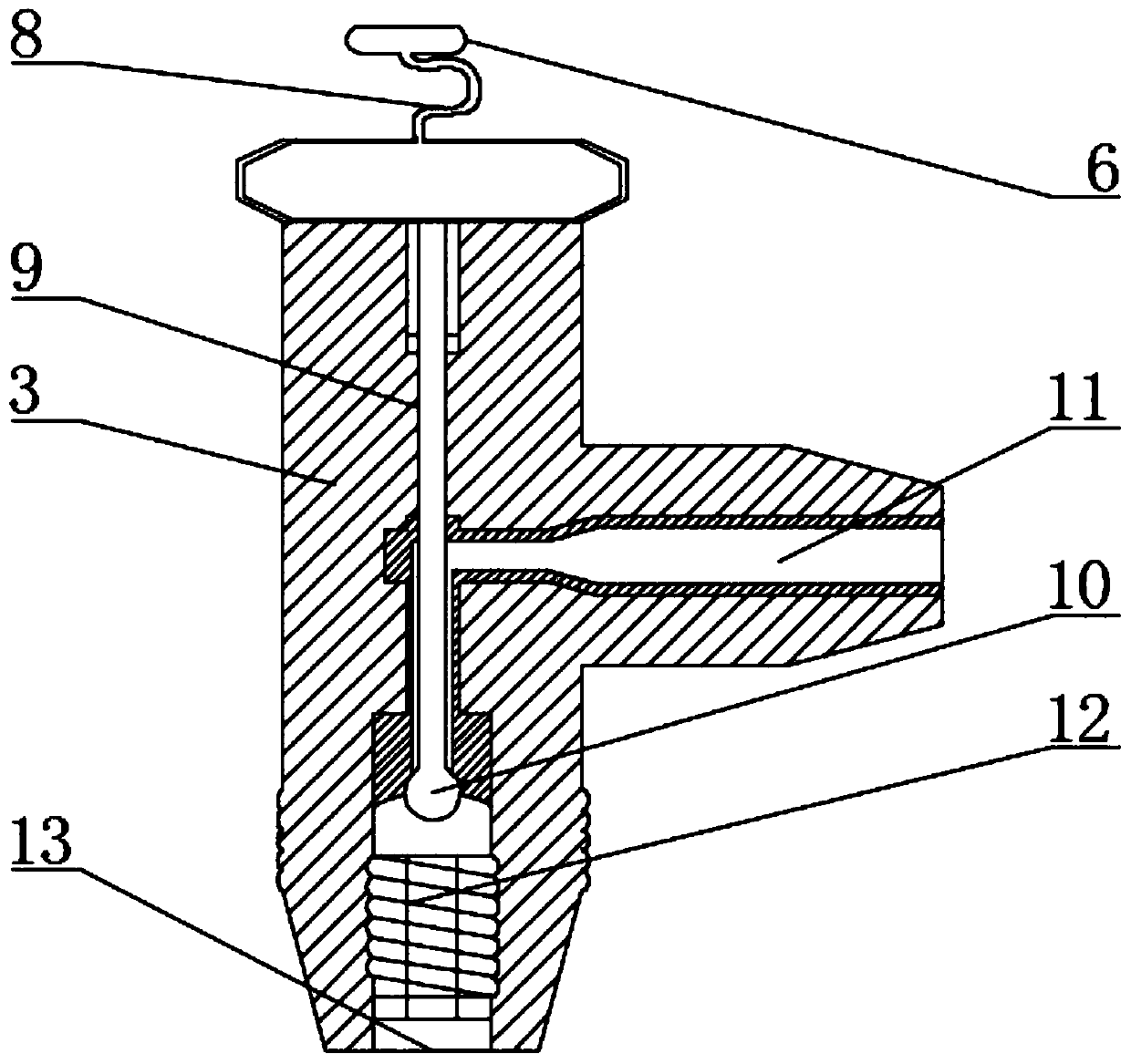

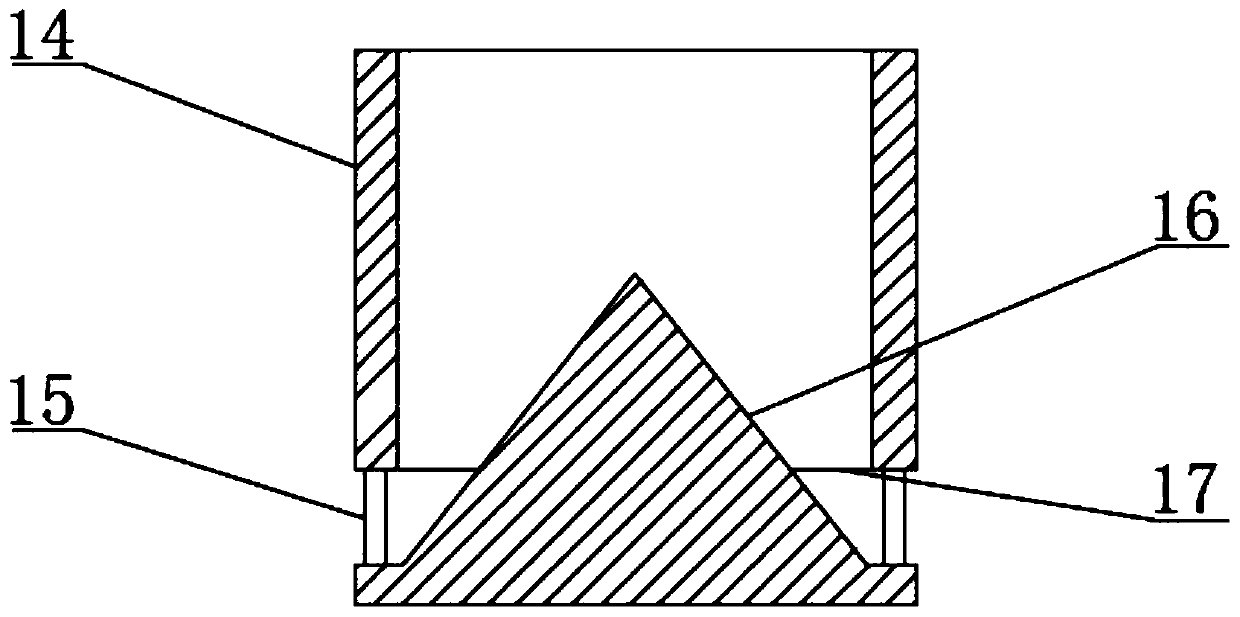

[0020] Such as Figure 1-4 As shown, a differential pressure mine automatic fire extinguisher based on a new type of fire extinguishing agent includes a high-pressure fire extinguishing tank 1, a delivery pipeline 2 is connected to the outer surface of one end of the high-pressure fire extinguishing tank 1, an expansion valve 3 is arranged on the inside of the delivery pipeline 2, and the delivery pipeline The other end of 2 is provided with a connector 4, one side of the connector 4 is provided with multiple groups of atomizing nozzles 5, the outer surface of the lower end of the delivery pipe 2 is provided with a fire source detector 6, and the outer surface of one end of the high-pressure fire extinguishing tank 1 is close to the expansion The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com