Split type static pressure gas bearing device with adjustable swing angle and for rotor static balance

A static pressure gas bearing and static balance technology, which is applied in the field of bearing devices and static pressure gas bearing devices, can solve the problems of large friction resistance, ball wear, and the inability to apply rotor static balance device, and achieve the effect of avoiding the wear of the shaft seat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

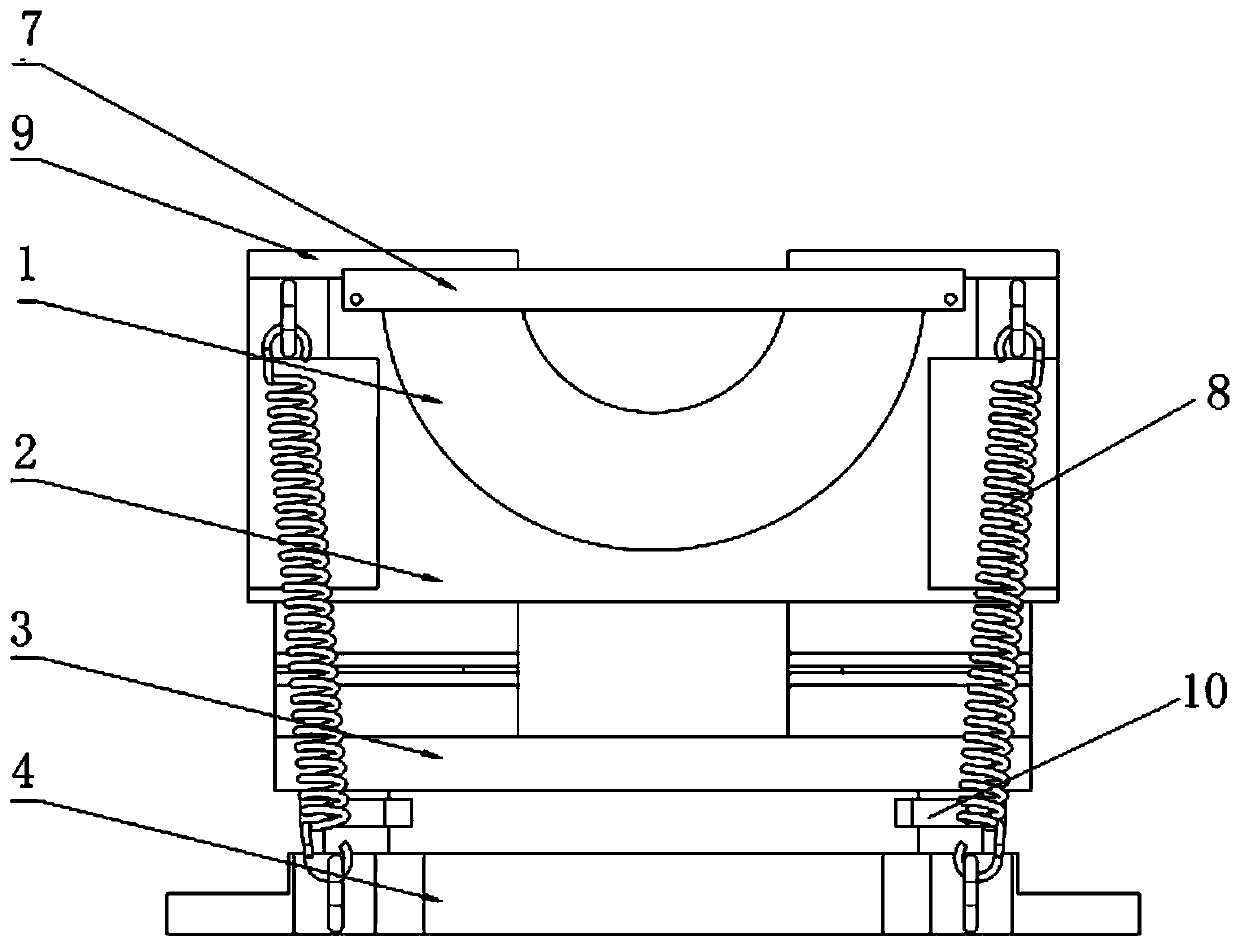

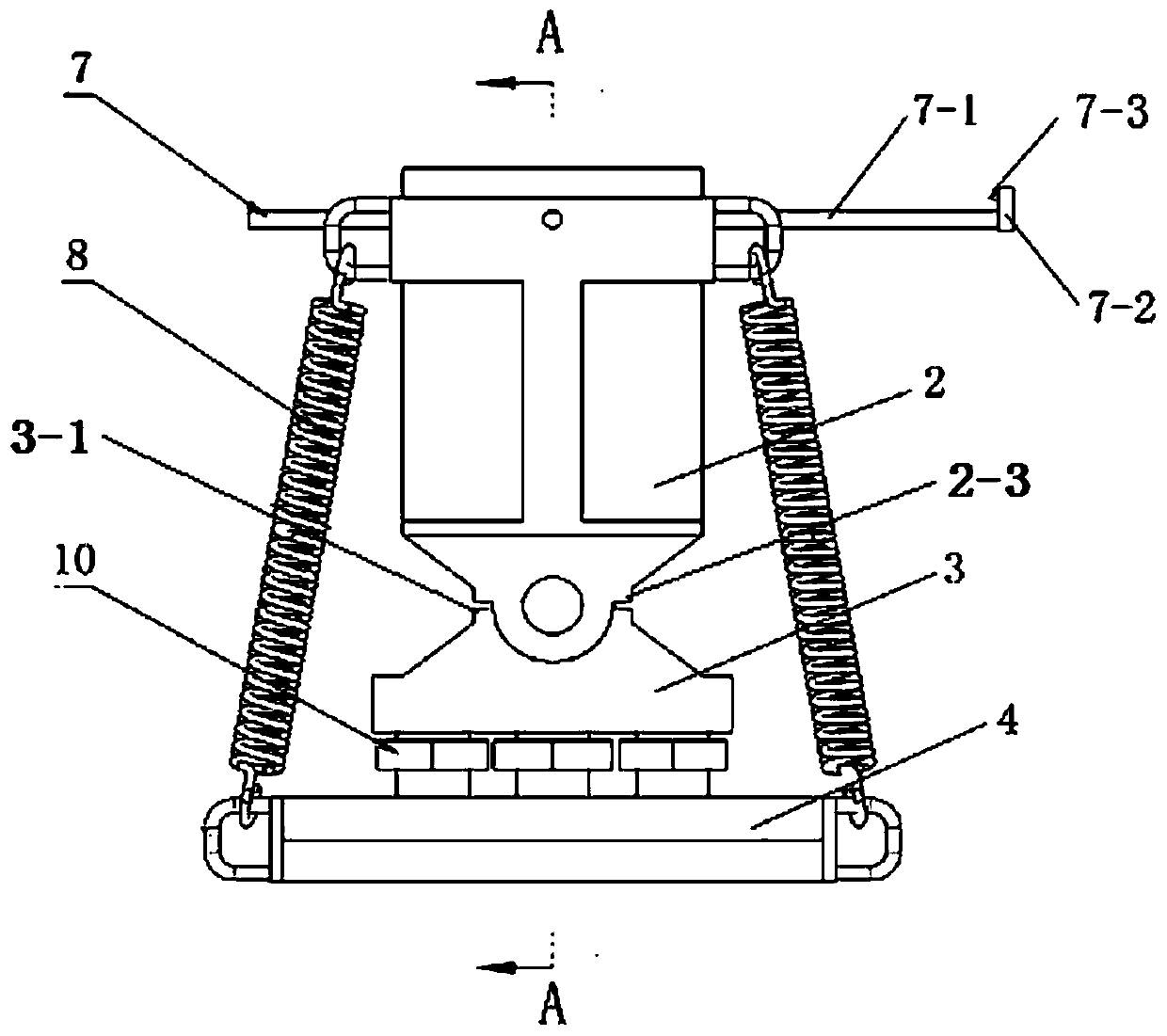

[0022] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 10 To illustrate this embodiment, this embodiment includes a shaft seat 1, an upper support 2, a lower support 3, a base 4 and an air intake passage 5;

[0023] A concave first semi-cylindrical surface is processed on the shaft seat 1, and the first semi-cylindrical surface faces upwards, and a plurality of air holes 1-1 are processed on the first semi-cylindrical surface, and the shaft seat 1 is fixed on the upper support On the base 2, a sealed air chamber 6 is provided between the shaft seat 1 and the upper support 2, and a plurality of air holes 1-1 communicate with the sealed air chamber 6, and the sealed air chamber 6 is connected to the external air supply device through the air intake channel 5 , the upper support 2 and the lower support 3 are hinged so that the axis of the semi-cylindrical surface can swing a certain angle along the vertical direction, and the ...

specific Embodiment approach 2

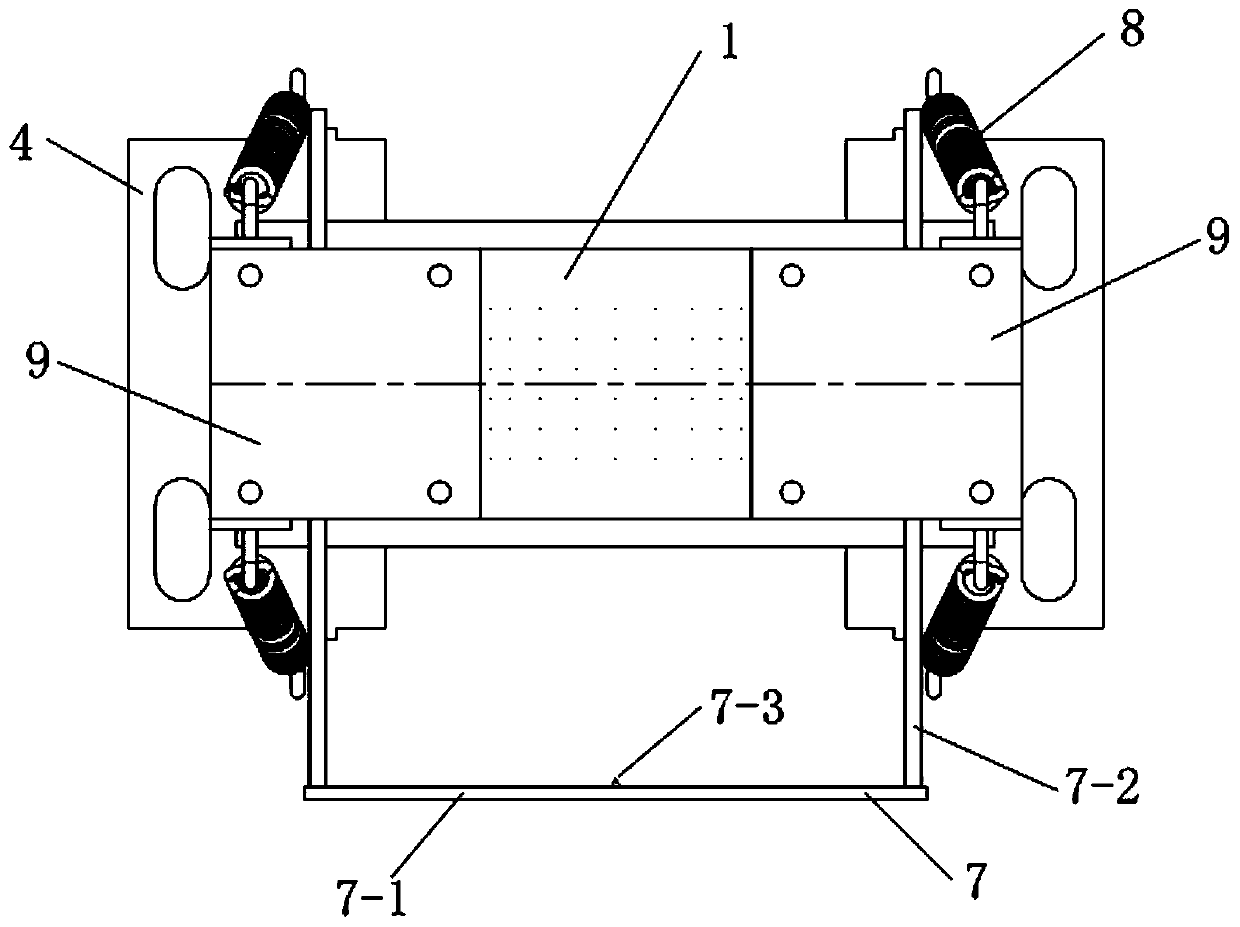

[0025] Specific implementation mode two: combination figure 2 and image 3 To illustrate this embodiment, this embodiment also includes an axial positioning device 7, the axial positioning device includes a baffle 7-1, two guide rods 7-2 and an axial limit shaft 7-3;

[0026] The two guide rods 7-2 are slidably arranged on the shaft seat 1, the baffle plate 7-1 is fixed on the two guide rods 7-2, the side of the baffle plate 7-1 facing the shaft seat 1 is processed with a bearing hole, and the bearing An axial limit shaft 7-3 is arranged in the hole, and a conical surface is processed on the axial limit shaft 7-3. The axis of the surface and the axes of the two guide rods 7-2 are parallel to each other, and the conical surface on the axial limit shaft 7-3 is concentric with the semi-cylindrical surface on the shaft seat 1. On the shaft seat 1 Two threaded holes are also processed on the top, and each threaded hole is provided with a top wire, and each top wire is pushed on ...

specific Embodiment approach 3

[0029] Specific implementation mode three: combination figure 2 and Figure 4 To illustrate this embodiment, the bottom of the lower support 3 in this embodiment is provided with three concave hemispherical surfaces, and the base 4 is processed with three threaded holes corresponding to the positions of the three concave hemispherical surfaces. Supporting screws 10 are provided in the holes, and the nuts of each supporting screw 10 are processed with outwardly convex hemispherical surfaces. The hemispherical surfaces on each supporting screw 10 match the hemispherical surfaces of each lower support 3, and the three The connecting line of any point on the respective axes of the two supporting screws 10 is a triangle.

[0030] With such arrangement, the supporting height of the axle seat 1 can be adjusted, and the axis of the axle seat 1 can be kept horizontal, which is convenient for installation.

[0031] Other compositions and connections are the same as in the first embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com