Magnetic gear, magnetic gear driver and motor

A technology of magnetic gears and transmissions, applied in transmissions, belts/chains/gears, mechanical equipment, etc., can solve the problems of increasing the iron loss of magnetic gears, low transmission precision, and reducing the transmission efficiency of magnetic gears, so as to prolong the service life. , the effect of improving accuracy, reducing drag and magnetic gear wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Magnetic Gear Embodiment

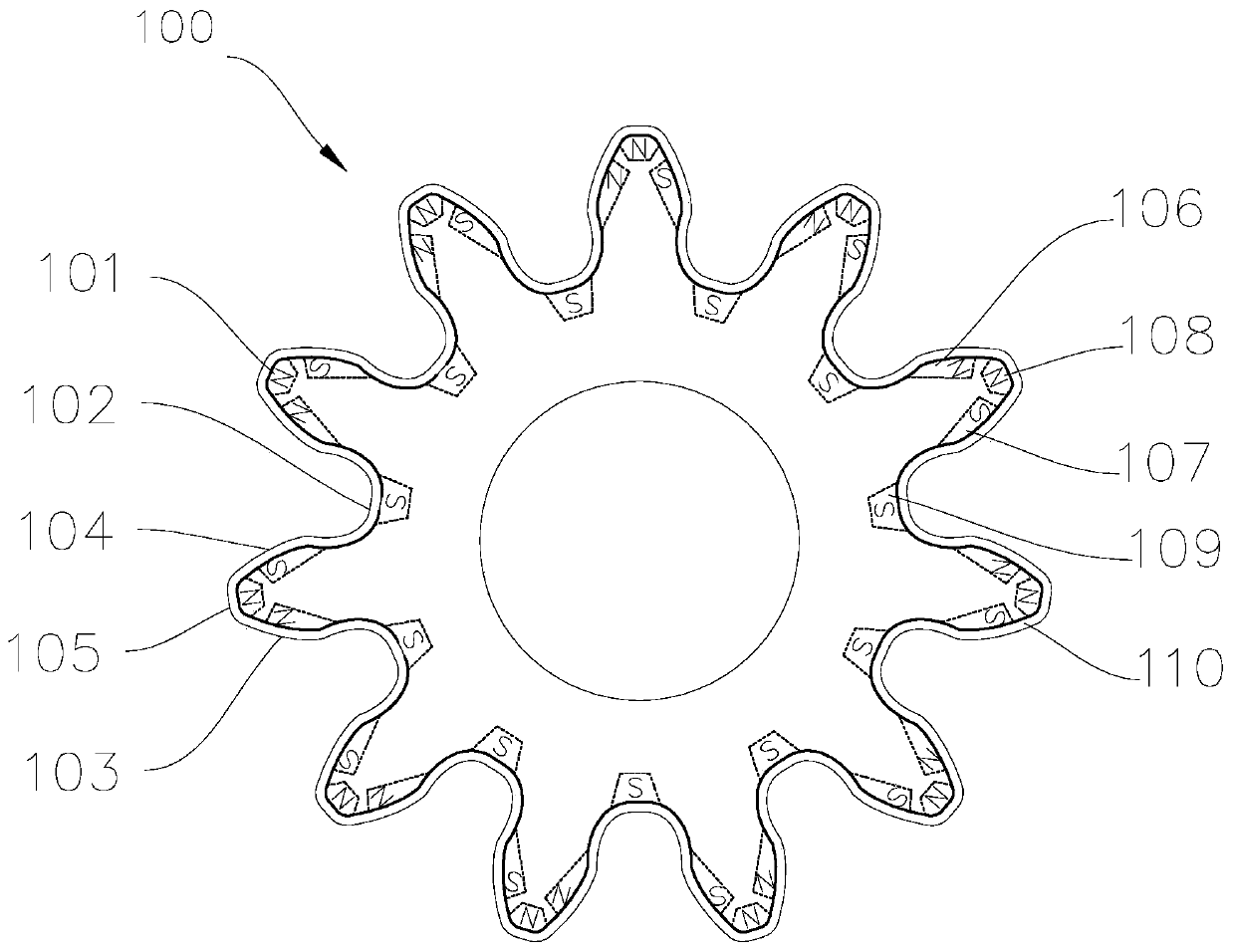

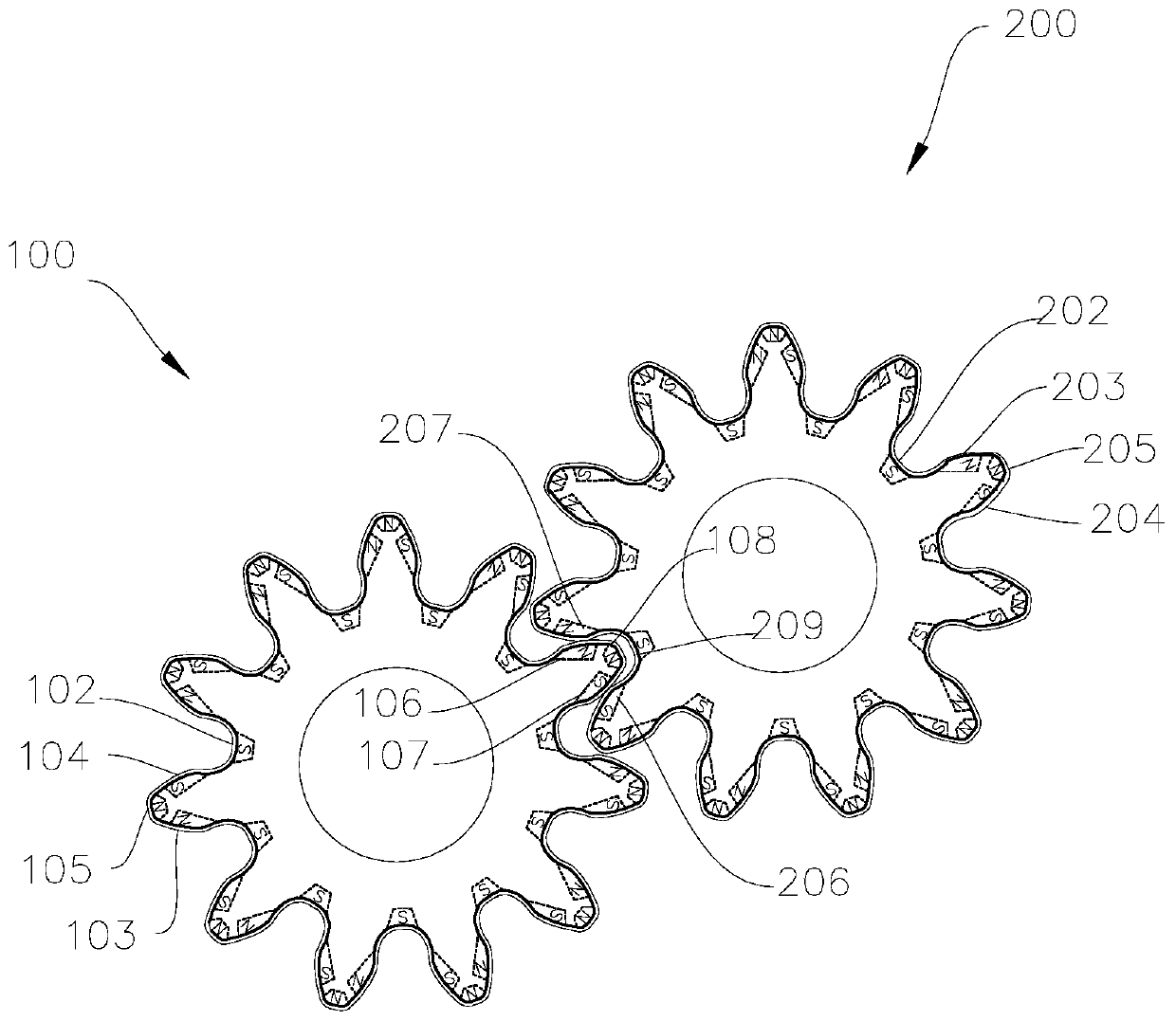

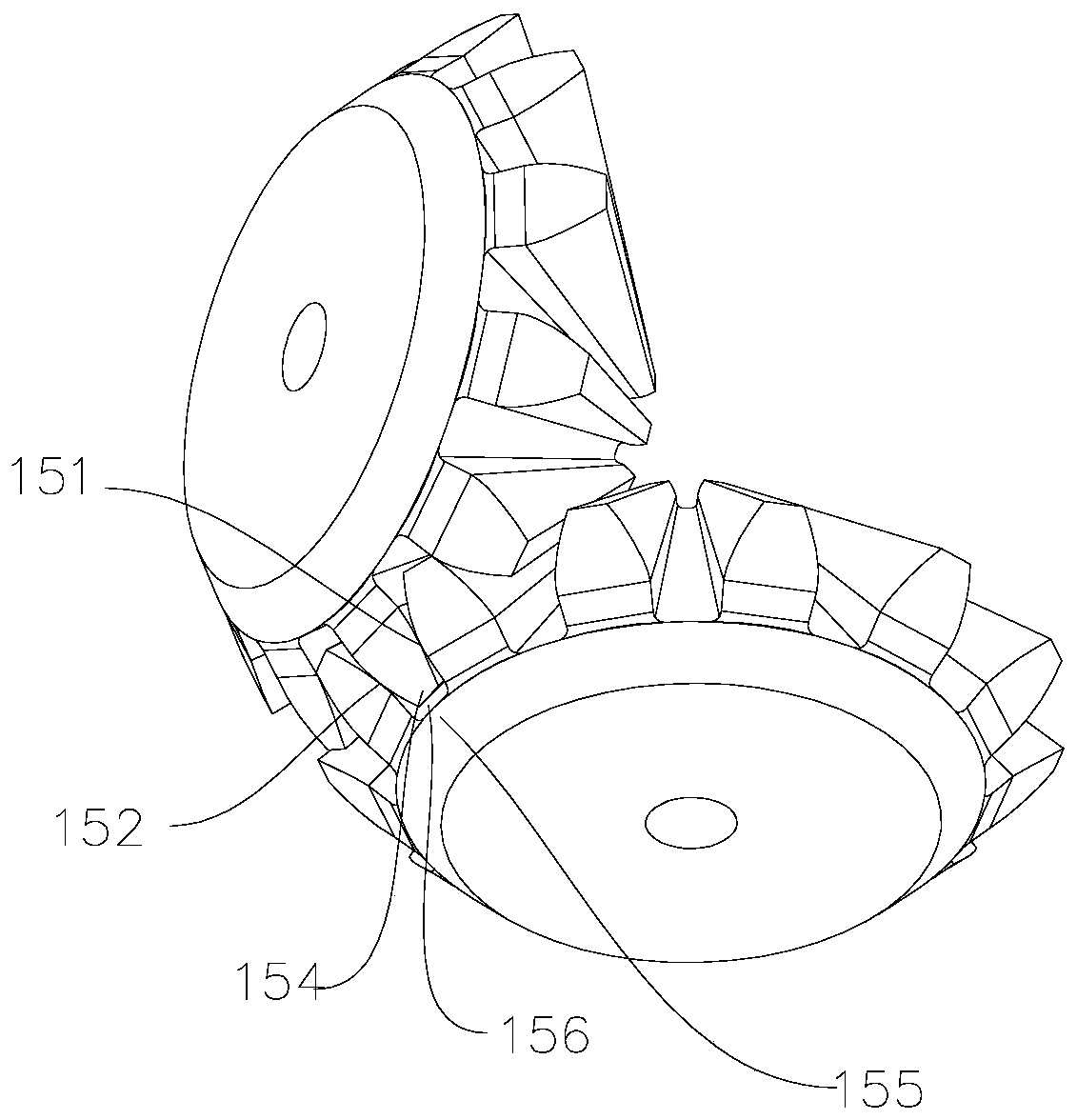

[0030] Such as figure 1 , figure 2 As shown, the magnetic poles N and S marked on the magnetic gear in the figure are the outer magnetic poles of the working surface of the gear teeth. The magnetic gear 100 includes gear teeth 101 and tooth slots 102 . The gear tooth comprises a first contact surface 103 , a second contact 104 and a tooth crest 105 . A first magnetic source 106 is provided at the first contact surface 103; a second magnetic source 107 is provided at the second contact surface 104; a third magnetic source 108 is provided at the crest 105; a fourth magnetic source is provided at the slot 102 109. The magnetic field strength of the first magnetic source 106 and the second magnetic source 107 is greater than the magnetic field strength of the third magnetic source 108 and the fourth magnetic source 109 .

[0031] The magnetic gear 100 is used in mesh with the magnetic gear 200 . The first magnetic source 106N pole of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com