Method for determining high-concentration filling slurry self-flowing conveying optimal slurry and application

A technology for filling slurry and determining methods, which is applied in filling, special data processing applications, earthwork drilling and mining, etc., can solve problems such as accuracy limitations, and achieve various performance guarantees, cost savings, blindness and workload reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention is described in detail below in conjunction with embodiment:

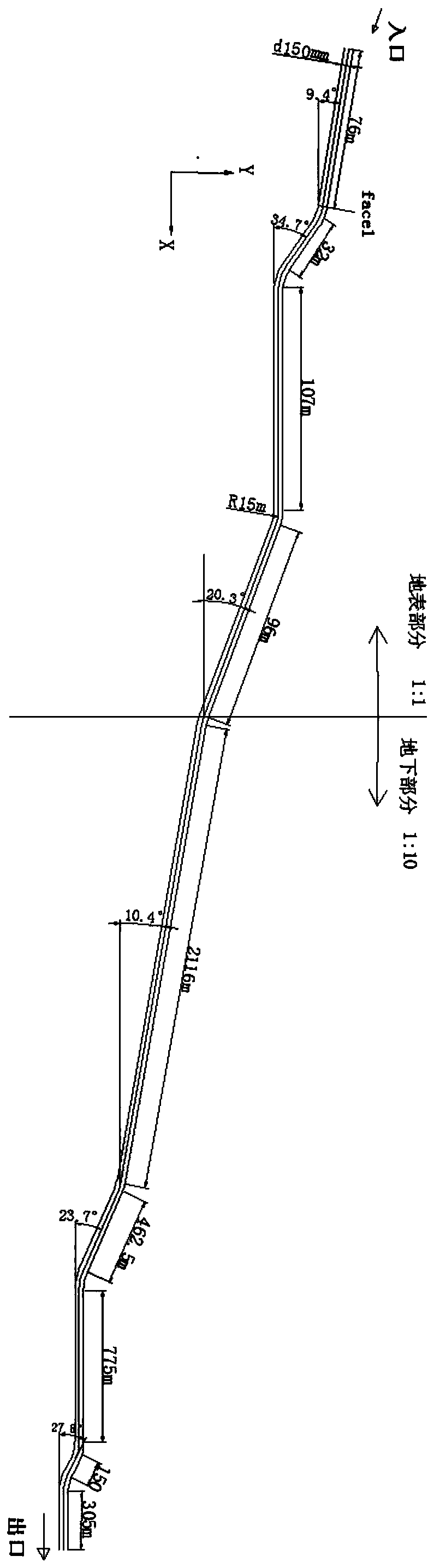

[0055] Step 1: The waste rock and tailings used in the experiment all come from a copper mine, and the density of the waste rock crushed aggregate is determined to be 2815kg / m 3 , the packing density is 0.554, the fine grain material passing through the 0.25mm sieve is 6.4%, and the particle size is mainly concentrated between -15mm and +7mm. Large particles in pipeline transportation are easy to deposit, which is not conducive to pipeline transportation, so waste rock must be mixed with fine materials to improve gradation, increase interstitial effect and aggregate density.

[0056] Step 2: The density of tailings is 2897kg / m 3 , the packing density is 0.506, the weighted average particle size of tailings d 50 =0.149mm, the tailings gradation index n=0.501, the gradation is reasonable and the compactness is good. Generally speaking, the particle size of copper ore tailings is relati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com