BSI image sensor and manufacture thereof

An image sensor and back-illuminated technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems affecting the quantum conversion efficiency of photoreceptors, production process mutual constraints, and device performance cannot be truly optimized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

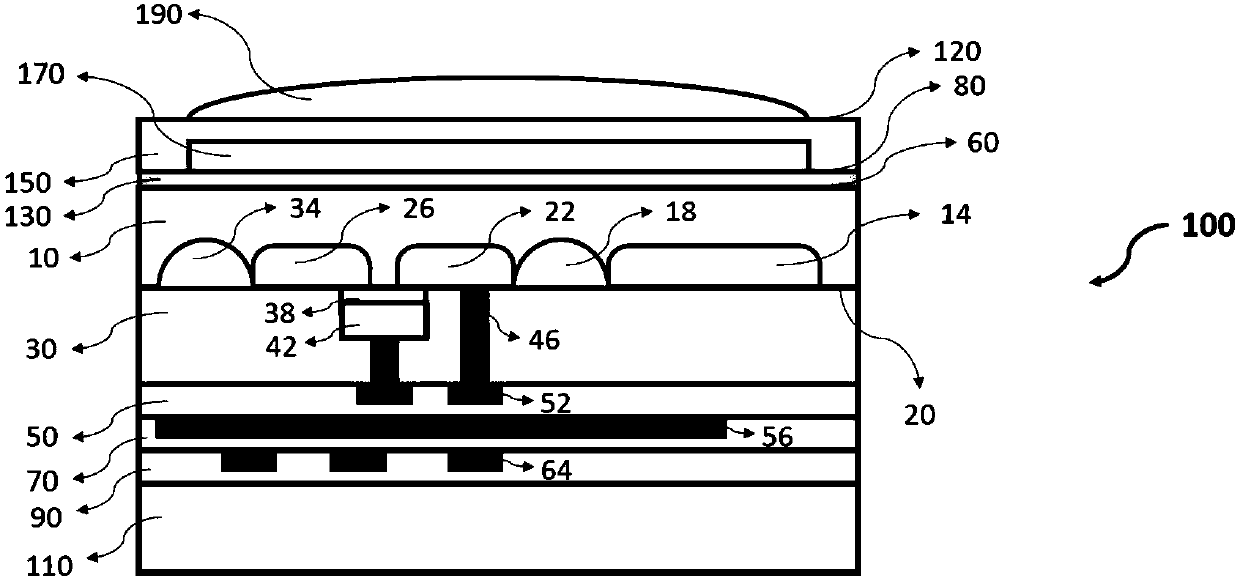

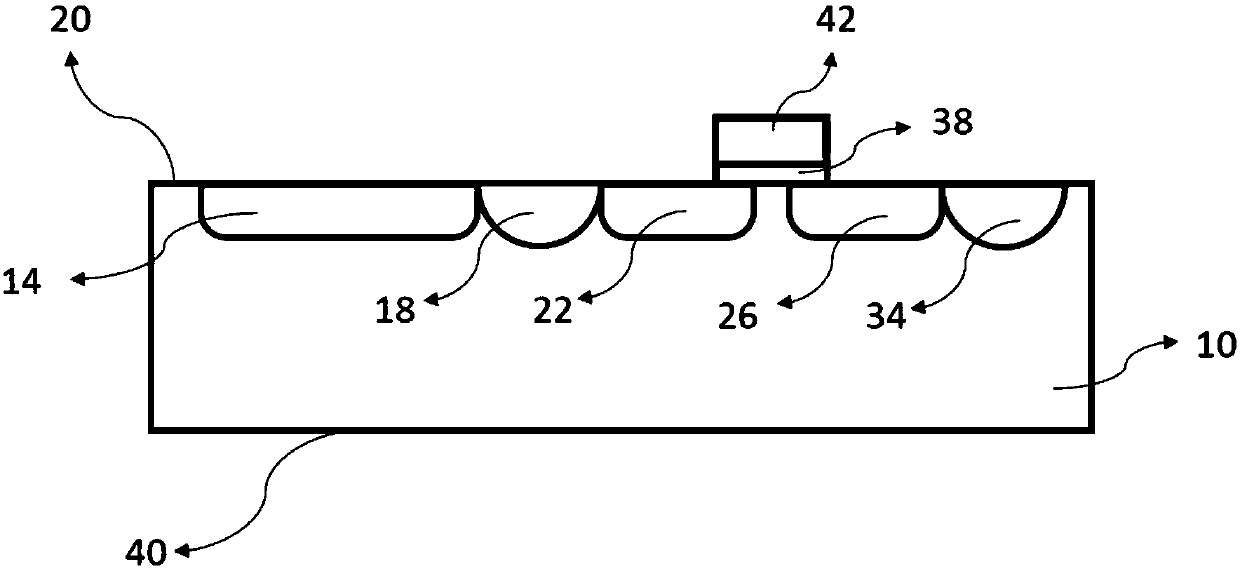

[0062] Embodiments of the present invention relate to a back-illuminated image sensor and a manufacturing method thereof according to an embodiment of the present invention, in particular, to a back-illuminated image sensor based on a heterojunction photoreceptor and a manufacturing method thereof according to an embodiment of the present invention method.

[0063] Referring to the drawings, the same or similar reference numerals are used throughout the various embodiments of the present invention to denote the same and similar elements in different drawings.

[0064]Since the present invention is about a back-illuminated image sensor based on heterojunction photoreceptors, the structure of the circuit part of the back-illuminated image sensor can basically adopt the prior art in the art (for example, U.S. Patent No. US7,875,948B2 ) in the known circuit structure and manufacturing process, in the following embodiments, the present invention only focuses on the differences and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com