Disc motor winding

A disc motor and winding technology, which is applied to the shape/style/structure of the winding conductor to achieve the effects of high tensile strength, large winding cross-sectional area, and easy insulation gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

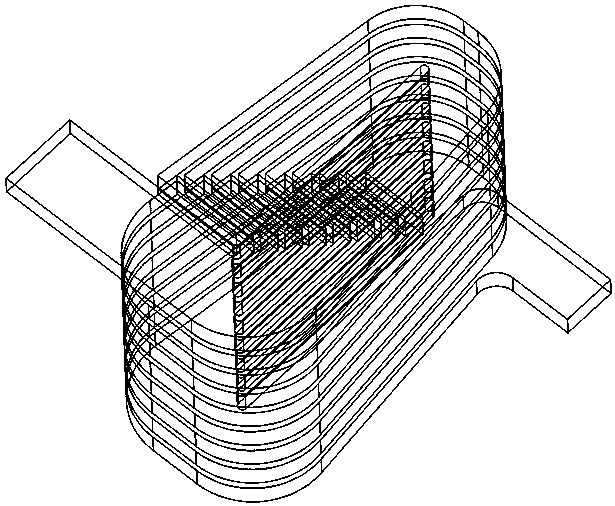

[0038] see Figure 1 to Figure 6 , the disc motor winding is characterized in that: each phase winding adopts a variable cross-section structure, and the radial cross-section gradually increases from the inside to the outside; the windings of the variable cross-section units are connected through progressive connections to achieve layered arrangement to form a winding Basic parts; the winding basic parts are covered with insulating materials or high-strength supporting materials to improve the insulation level and structural strength; the winding basic parts in different helical directions are connected according to the actual winding arrangement principle to form the stator windings of each phase, providing the time required for the direction. Variable magnetic field; the winding structure of the disc motor has strong adaptability and is suitable for slotted and slotless disc motors. The winding of the disk motor described in the invention has simple structure, high strength,...

Embodiment 2

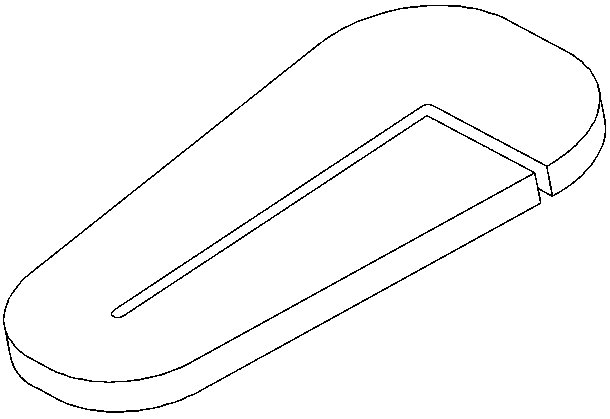

[0039] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows: the unit winding of the disc motor winding ( figure 1 ) is a winding with variable cross-section, that is, the cross-section near the inner circle of the winding is smaller, and the cross-section near the outer circle of the winding is larger.

[0040] Sections of the unit windings include, but are not limited to, rectangular windings, circular windings, and the like.

[0041] The unit winding includes, but is not limited to, it is made of a whole piece of conductive material by wire cutting, or it is made of multiple pieces of conductor material welded, or it is made of a whole piece of conductor bent. The center gap of the unit winding can be determined by the actual required creepage distance Depends on the level of insulation.

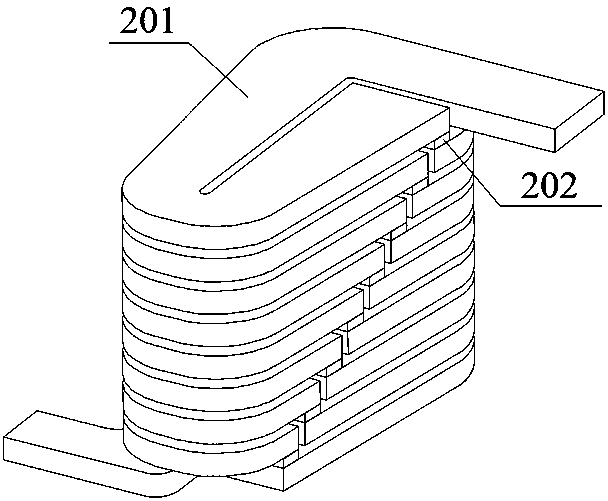

[0042] In particular, the unit windings can be formed by progressive connections ( figure 2 ).

[0043] The progressive connect...

Embodiment 3

[0050] Embodiment three, this embodiment is basically the same as embodiment two, and the special features are as follows:

[0051] The disk motor winding structure and its manufacturing method are suitable for slotted disk motors. The size of the central gap of the unit winding is determined by the structure of the stator slot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com