Glass plate production method and automotive glass plate

A manufacturing method and technology for glass plates, which are applied to windshields, chemical instruments and methods, glass/slag layered products, etc., can solve the problems of scratches on the anti-fog layer, inability to exert anti-fog properties, and reduced anti-fog functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Hereinafter, an embodiment (hereinafter also referred to as "this embodiment") according to one aspect of the present invention will be described based on the drawings. However, this embodiment described below is an illustration of the present invention in all points. Various improvements and modifications can of course be made without departing from the scope of the present invention. That is, when implementing the present invention, specific configurations corresponding to the embodiments can be appropriately employed. In addition, in the following description, for convenience of description, it demonstrates based on the direction in a drawing.

[0086] §1 Composition example

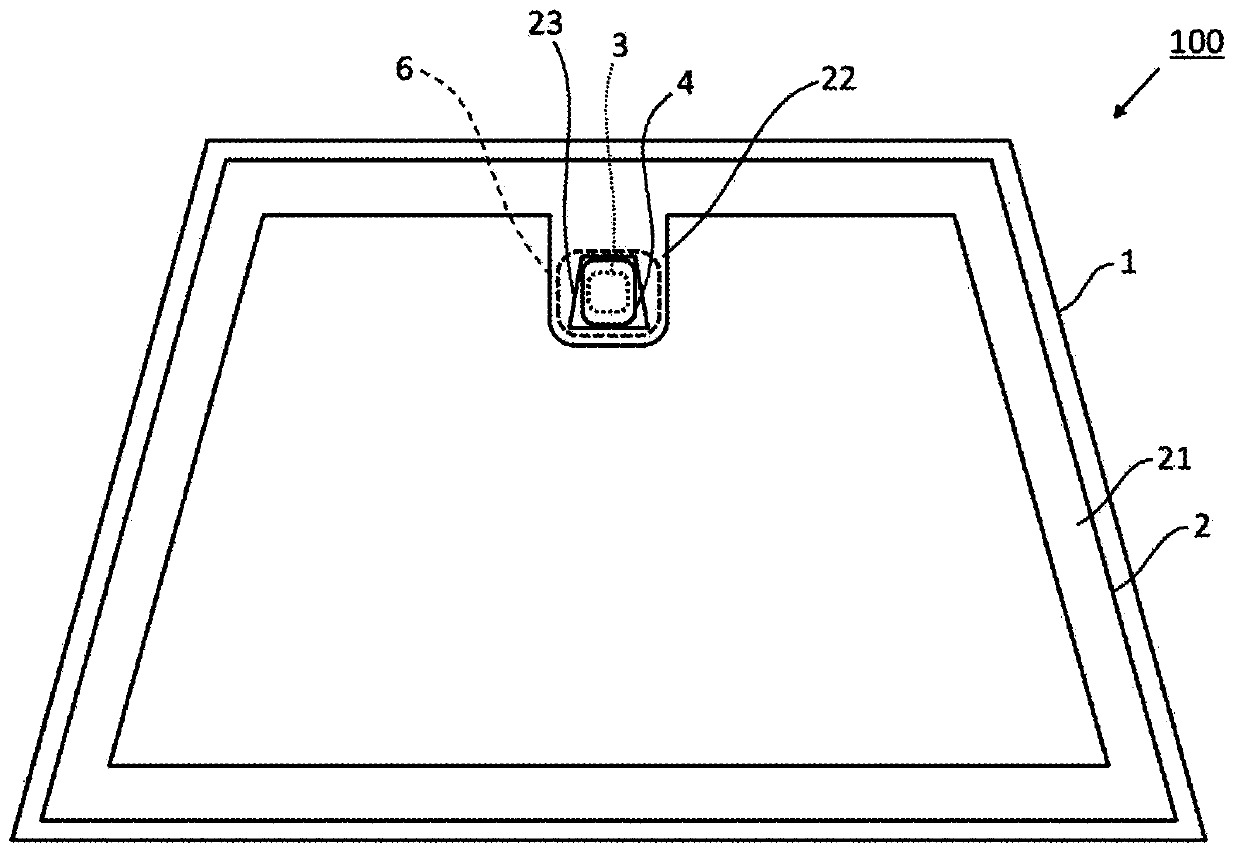

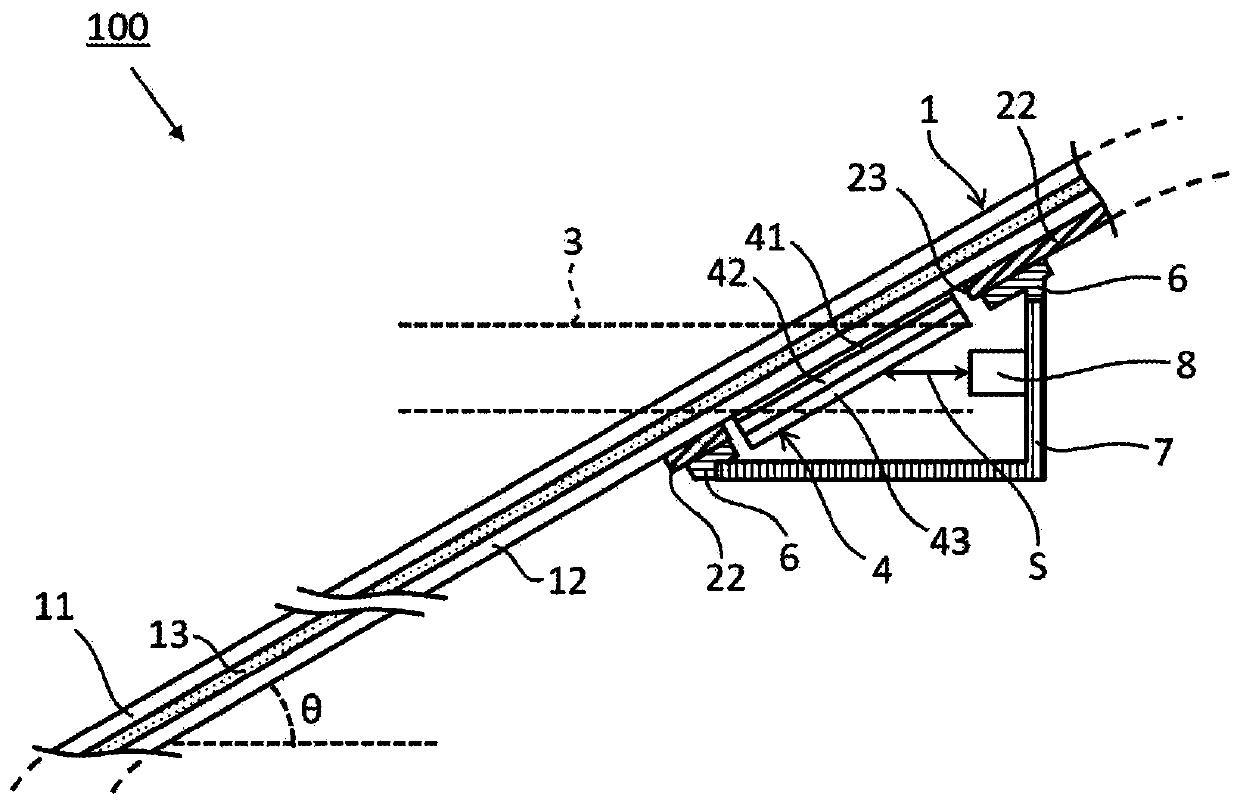

[0087] First, use figure 1 with figure 2 Windshield 100 according to this embodiment will be described. figure 1 with figure 2 It is a front view and a cross-sectional view schematically illustrating an example of the windshield 100 according to the present embodiment.

[0088] Such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com