Stirring homogenization device for food detection

A food testing and mixing tank technology, which is applied in the direction of measuring devices, testing food, material inspection products, etc., can solve the problems of low stirring efficiency and small stirring range of food samples, and achieve the goal of improving stirring efficiency, improving stirring range and stirring degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

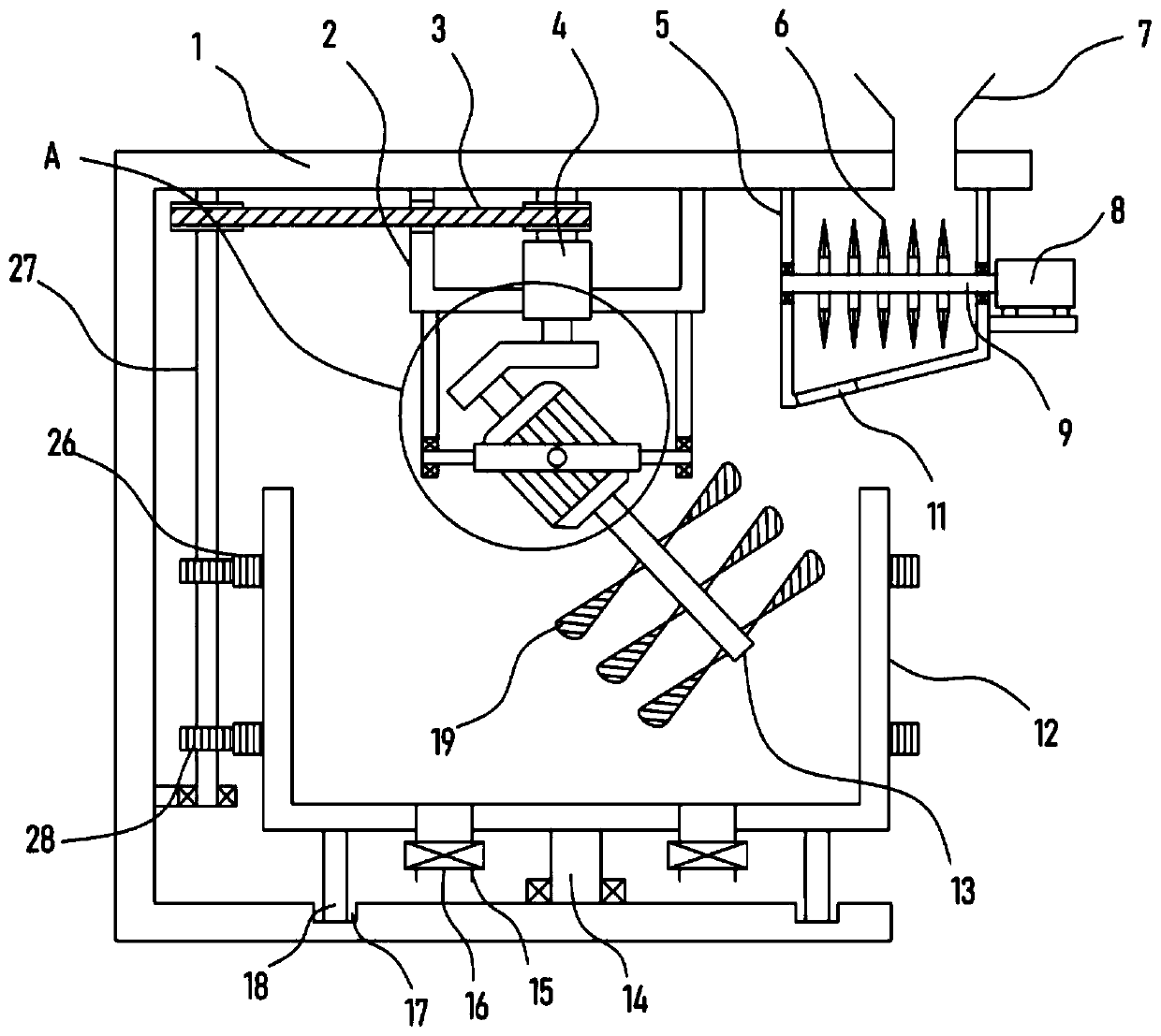

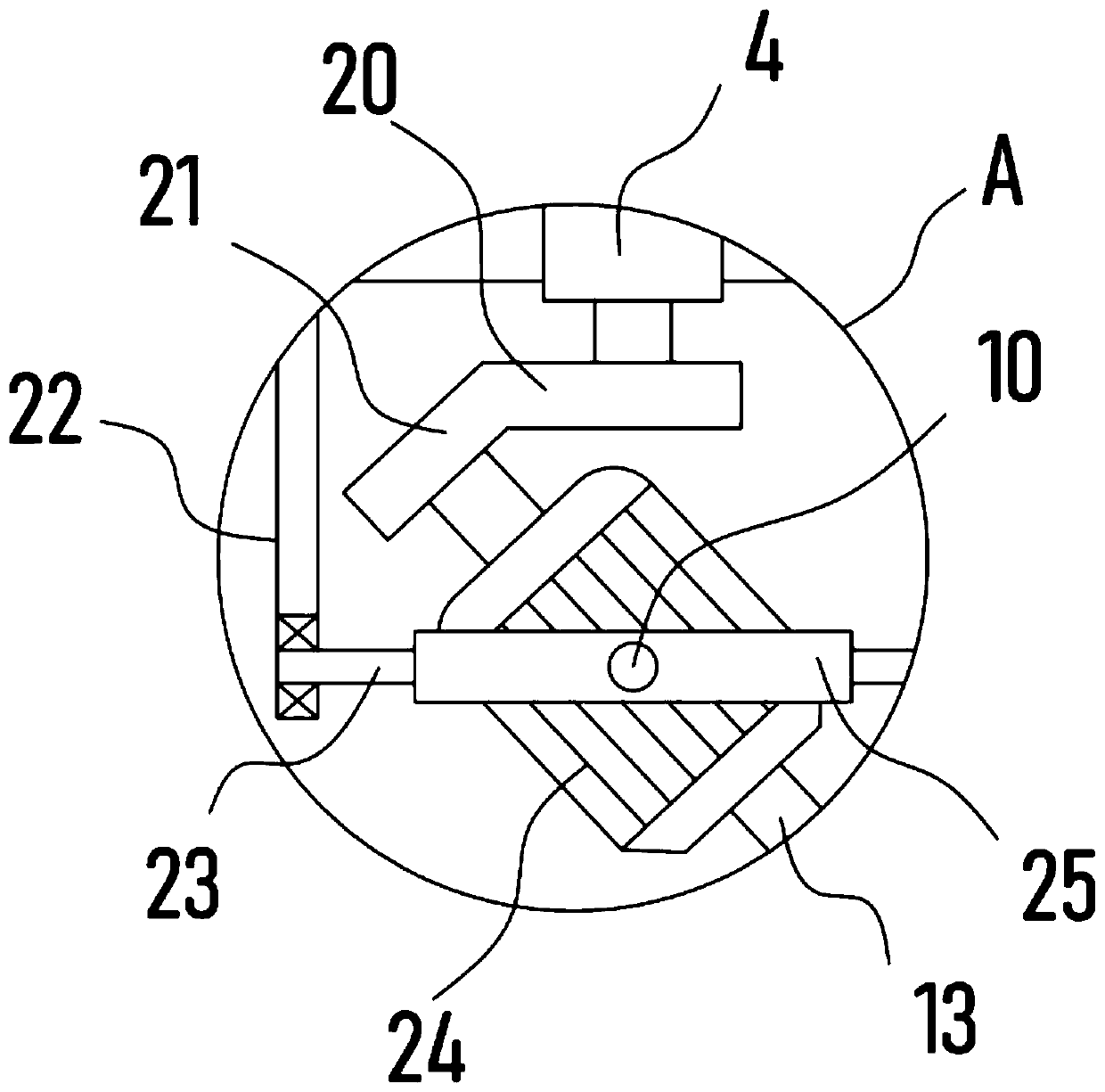

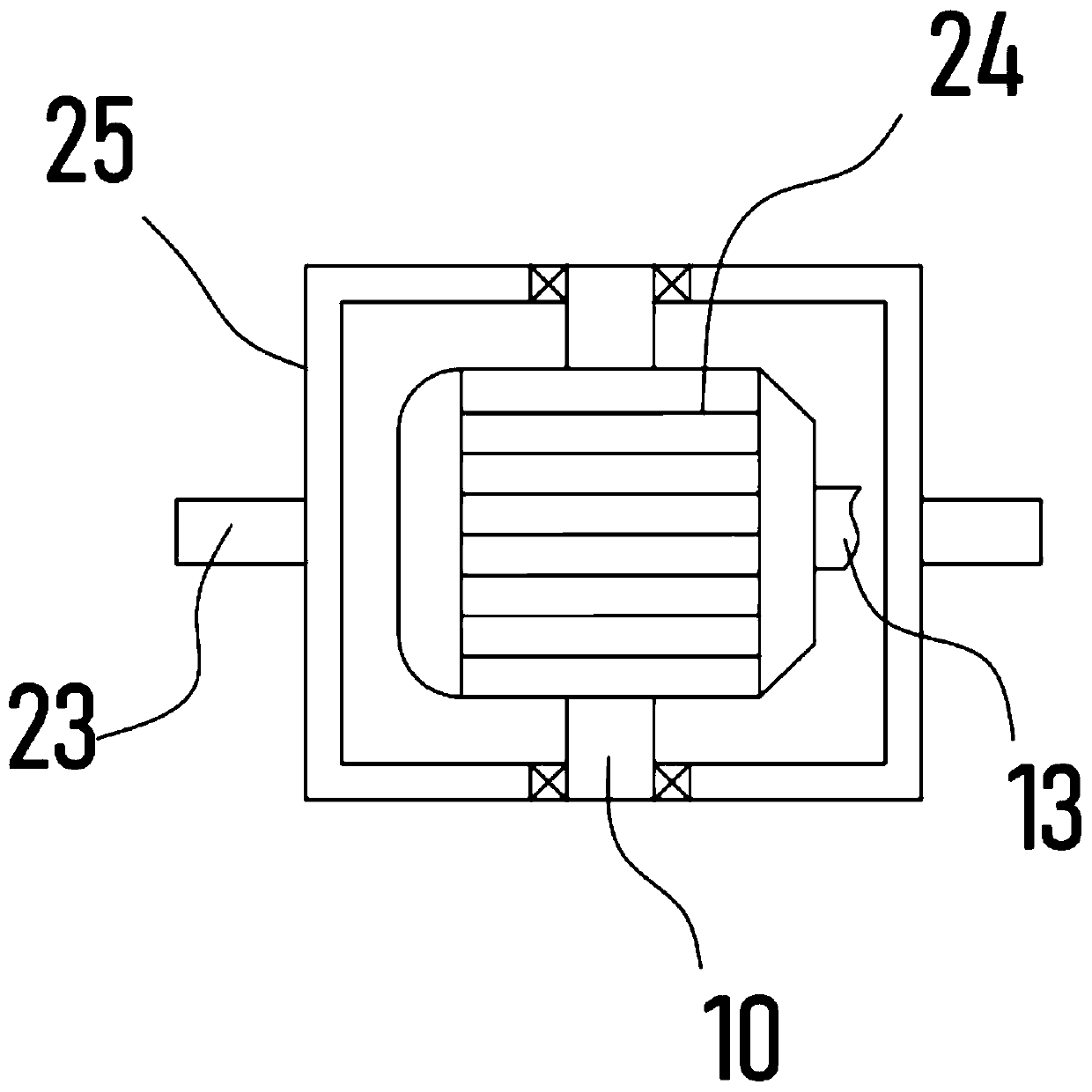

[0021] see Figure 1-3 , a stirring and homogenizing device for food detection, comprising a support frame 1, a mixing tank 12 and a crushing mechanism are installed on the support frame 1, a discharge pipe 15 is installed at the bottom of the mixing tank 12, and a discharge valve is installed on the discharge pipe 15 16. A fixed frame 2 is fixed on the top of the support frame 1, and a hanger 22 is fixed on the bottom of the fixed frame 2. The limit frame 25 is pivoted on the hanger 22, and the stirring motor 24 is installed on the limit frame 25. The output of the stirring motor 24 A stirring shaft 13 extending into the mixing barrel 12 is fixed coaxially, and several pairs of stirring blades 19 are fixedly mounted on the surface of the stirring shaft 13 at equal intervals.

[0022] Before food detection, the sample to be stirred is placed in the mixing tank 12, the stirring motor 24 is set to drive the stirring shaft 13 to rotate, and the stirring shaft 13 drives the stirri...

Embodiment 2

[0026] In order to further enhance the degree of agitation of the food samples in the mixing tank 12 and improve the mixing efficiency, on the basis of Embodiment 1, in addition, the mixing tank 12 is rotatably installed on the support frame 1, and the outer surface of the support frame 1 is sleeved and fixed with an outer The ring gear 26 is rotated vertically on the support frame 1 and is provided with a driven shaft 27. The driven shaft 27 is sleeved and fixed with a transmission gear 28 meshing with the outer ring gear 26. The shaft is in drive connection with the driven shaft 27 through the pulley mechanism 3 .

[0027] While the double-axis motor 4 drives the turntable 20 to rotate, the pulley mechanism 3 drives the driven shaft 27 to rotate, and the driven shaft 27 drives the transmission gear 28 on it to rotate, and the transmission gear 28 meshes with the outer ring gear 26 to realize the mixing tank 12 The rotation of the food sample makes the food sample rotate sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com