Painting device for camera shell

A paint coating device and camera technology, applied in the direction of the spray device, can solve the problems of easy precipitation and layering of paint, and achieve the effects of avoiding paint layering, saving power, and increasing the stirring area and stirring strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through specific implementations:

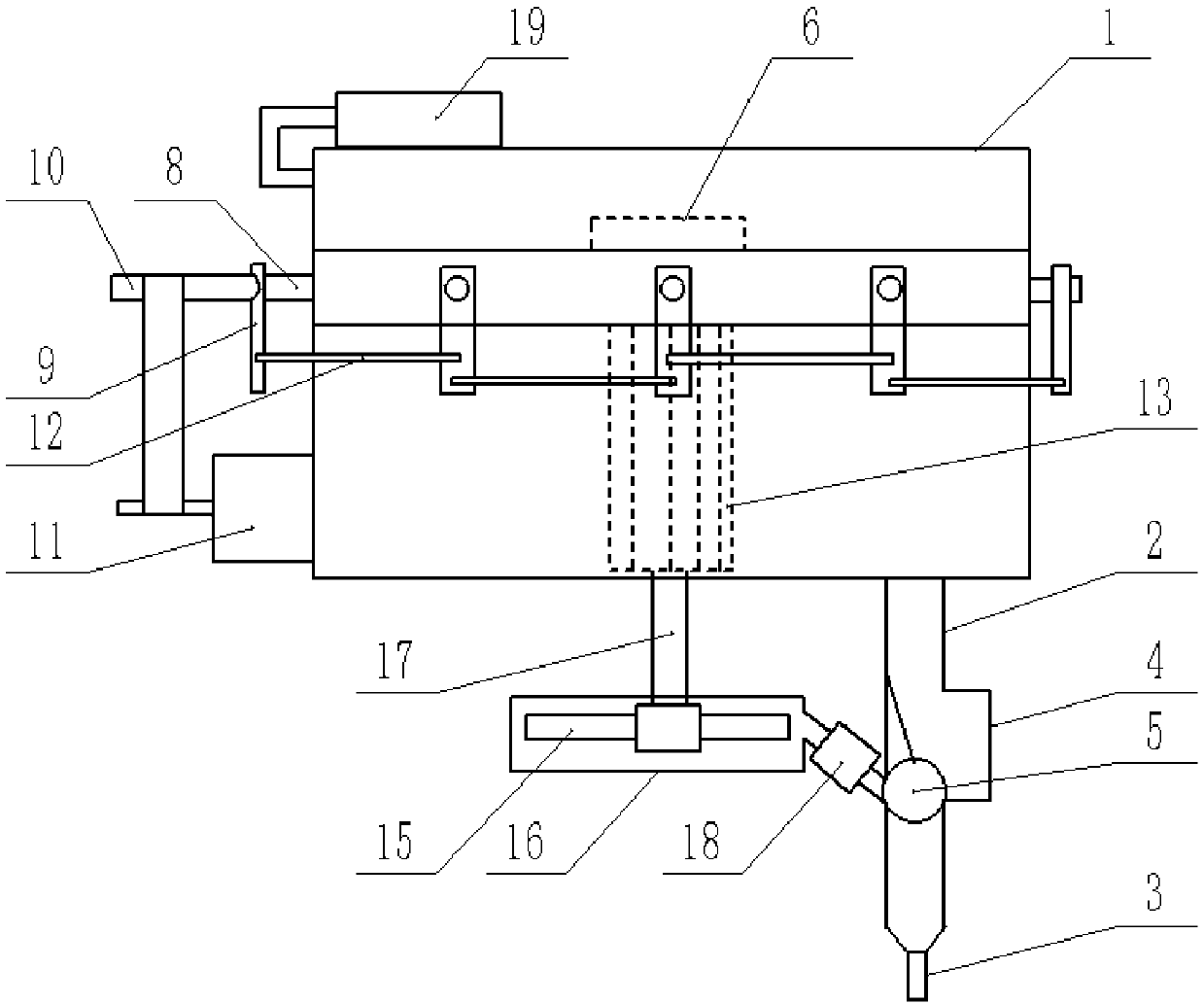

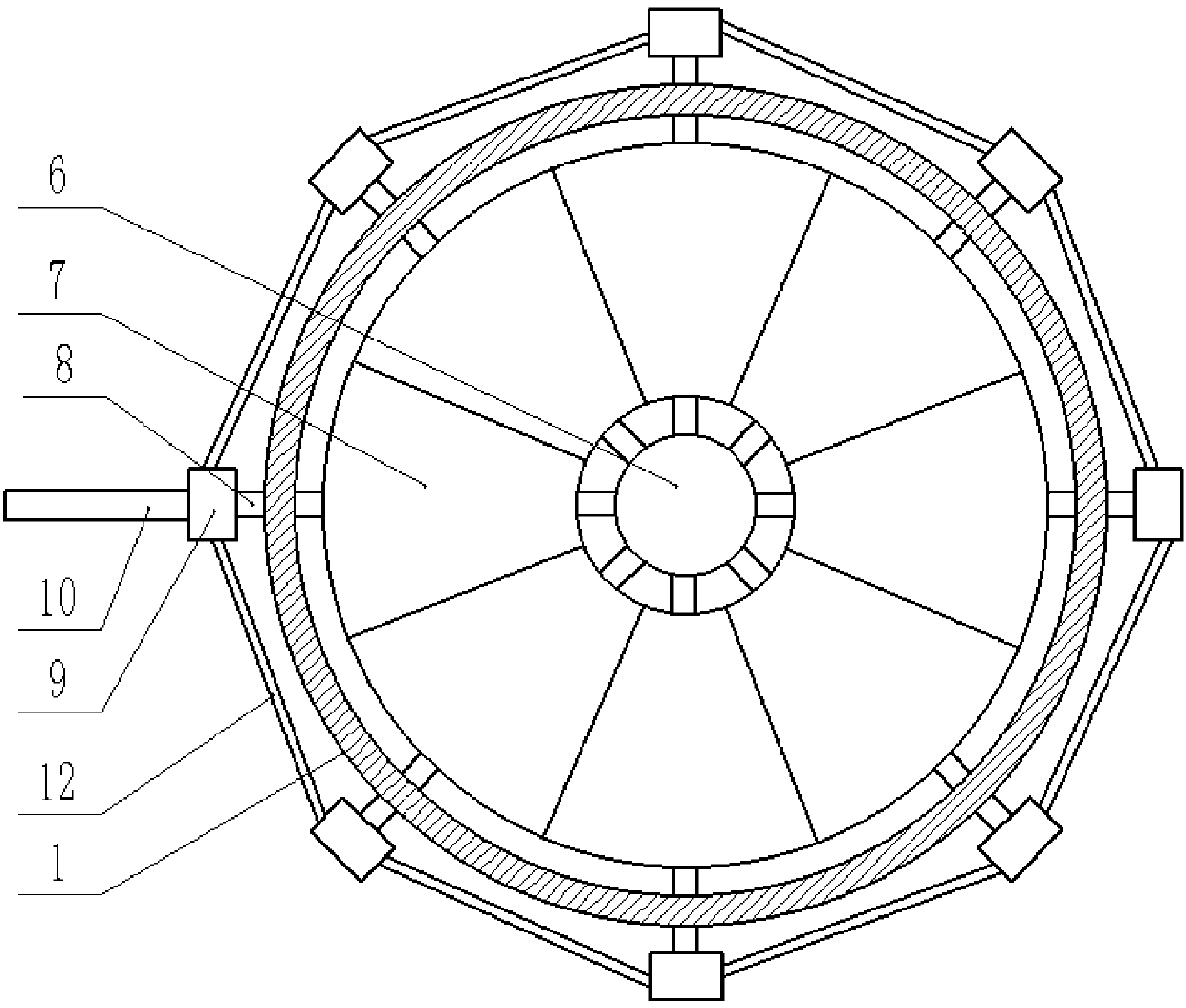

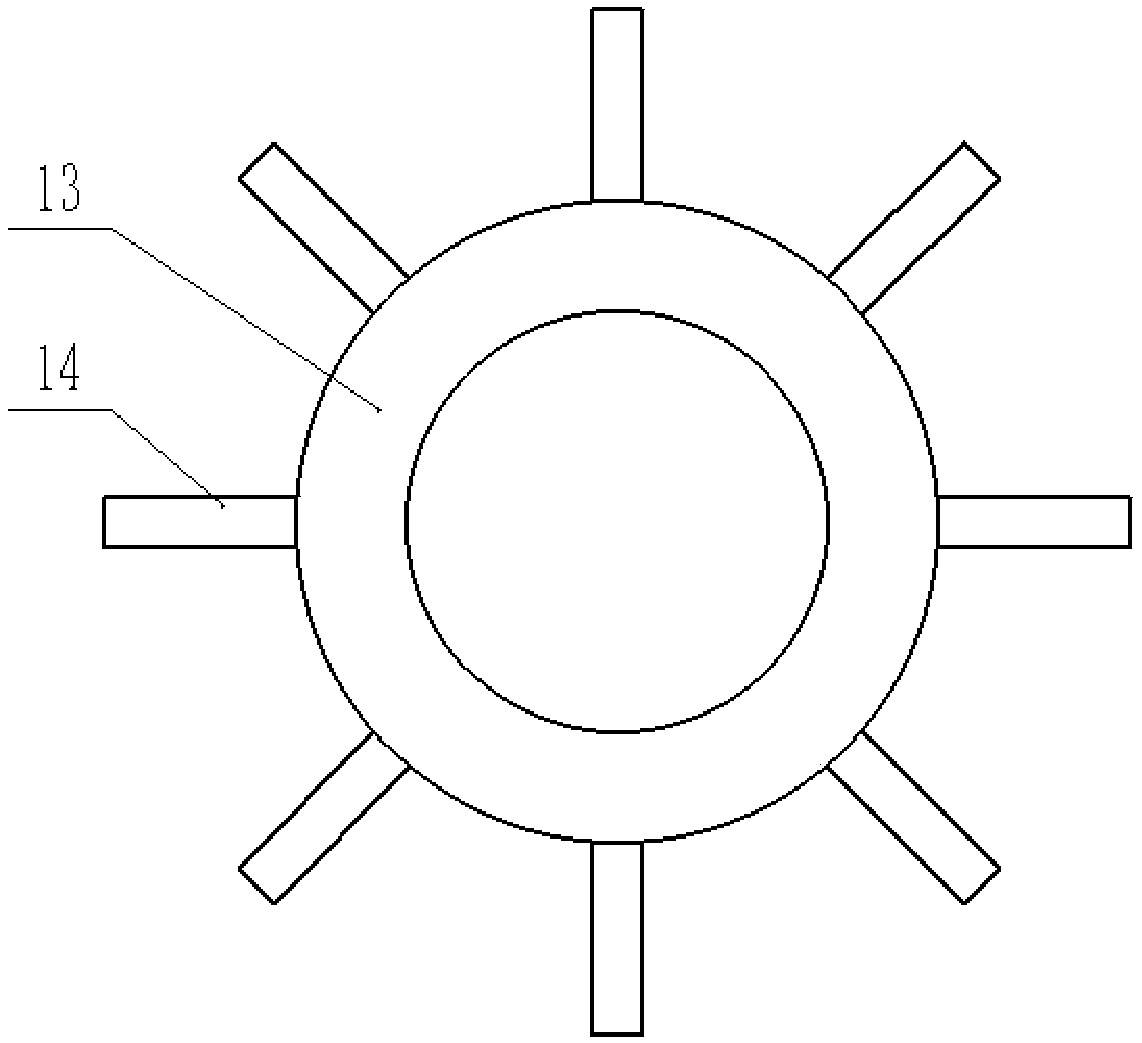

[0017] The reference signs in the drawings of the specification include: paint box 1, paint spray tube 2, spray head 3, convex part 4, plugging ball 5, central shaft 6, stirring paddle 7, connecting shaft 8, swing arm 9, transmission shaft 10 , Motor 11, connecting rod 12, rotating drum 13, vertical blade 14, fan blade 15, housing 16, rotating shaft 17, one-way valve 18, hot air blower 19.

[0018] The embodiment is basically like figure 1 Shown: a painting device for a camera housing, including a paint box 1, a paint spray tube 2 welded to the bottom of the paint box 1, and a spray nozzle 3 threaded on the lower end of the paint tube 2. The middle of the spray pipe 2 is provided with a convex part 4, the spray pipe 2 is provided with a plugging ball 5, and the plugging ball 5 is located at the junction of the convex part 4 and the spray pipe 2. The diameter of the plugging ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com