Household garbage recycling device

A technology for recycling device and domestic waste, applied in the direction of press, grain processing, manufacturing tools, etc., can solve the problem of unsatisfactory solid-liquid separation effect, and achieve the effect of convenient incineration operation, good effect and improved cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

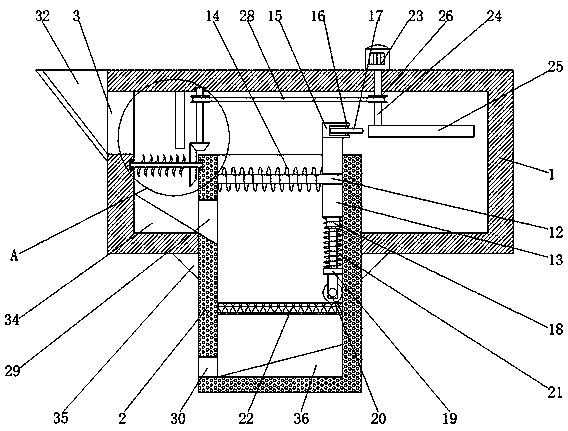

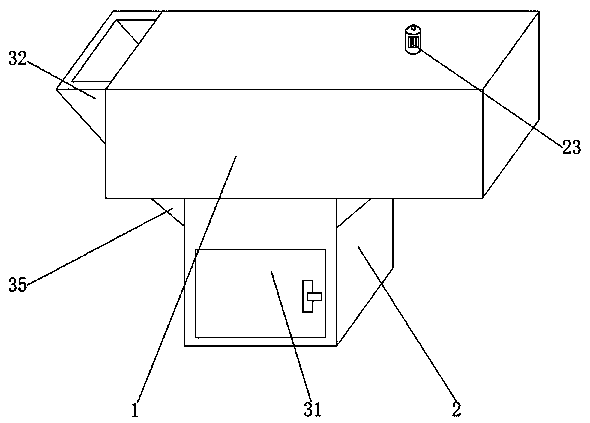

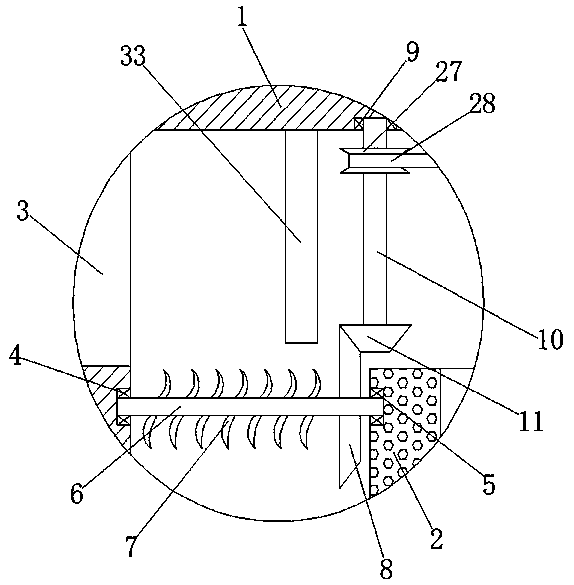

[0022] First implementation: see Figure 1-4, a domestic waste recovery device, comprising a first housing 1, the left side of the top of the inner wall of the first housing 1 is fixedly connected with a baffle 33, by setting the baffle 33, garbage is prevented from splashing everywhere, and the bottom of the inner wall of the first housing 1 The left side of the first guide block 34 is fixedly connected with the first lead block 34, and the left side of the first lead block 34 is fixedly connected with the left side of the inner wall of the first housing 1. By arranging the first lead block 34, it is convenient for the garbage to move and prevent the garbage from staying. Inside the first casing 1, the bottom of the first casing 1 is fixedly connected with the second casing 2, the top of the second casing 2 penetrates the first casing 1 and extends to its interior, and the left and right sides of the second casing 2 The side and the position at the bottom of the first housing...

no. 2 approach

[0025] The second embodiment: a domestic waste recovery device, including a first shell 1, the bottom of the first shell 1 is fixedly connected with a second shell 2, and the top of the second shell 2 passes through the first shell body 1 and extends to its interior, the top of the left side of the first housing 1 is provided with a feeding port 3, the left side of the top of the inner wall of the first housing 1 is fixedly connected with a baffle 33, and the first housing 1 1 The first rolling bearing 4 is fixedly connected in the groove on the left side of the inner wall and below the feeding port 3, and the second rolling bearing 5 is fixedly connected in the groove on the left side of the second housing 2 corresponding to the first rolling bearing 4, so The first rolling bearing 4 and the second rolling bearing 5 are flexibly connected by a crushing shaft 6, the surface of the crushing shaft 6 is fixedly connected with a plurality of crushing blades 7, and the size of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com