Blade spray protection fixture, blade spray protection method

A technology of protective clips and blades, which is applied in the direction of coatings, spraying devices, and devices for coating liquid on the surface, can solve the problems of no effective protection means, achieve effective spray protection, high pass rate, and reduce the cost of spray protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

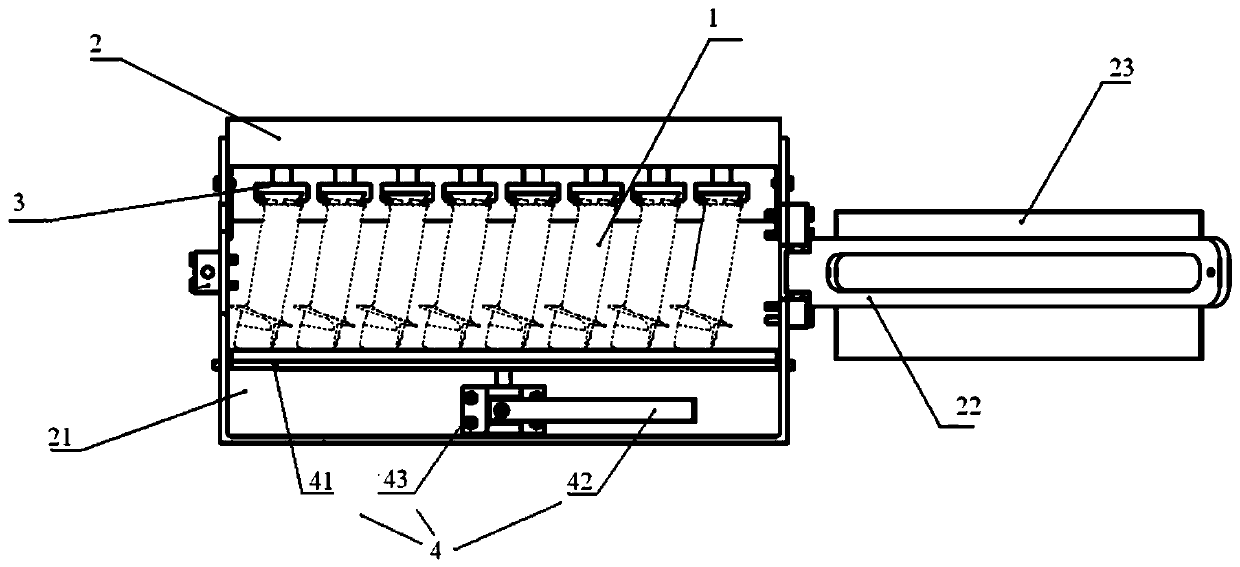

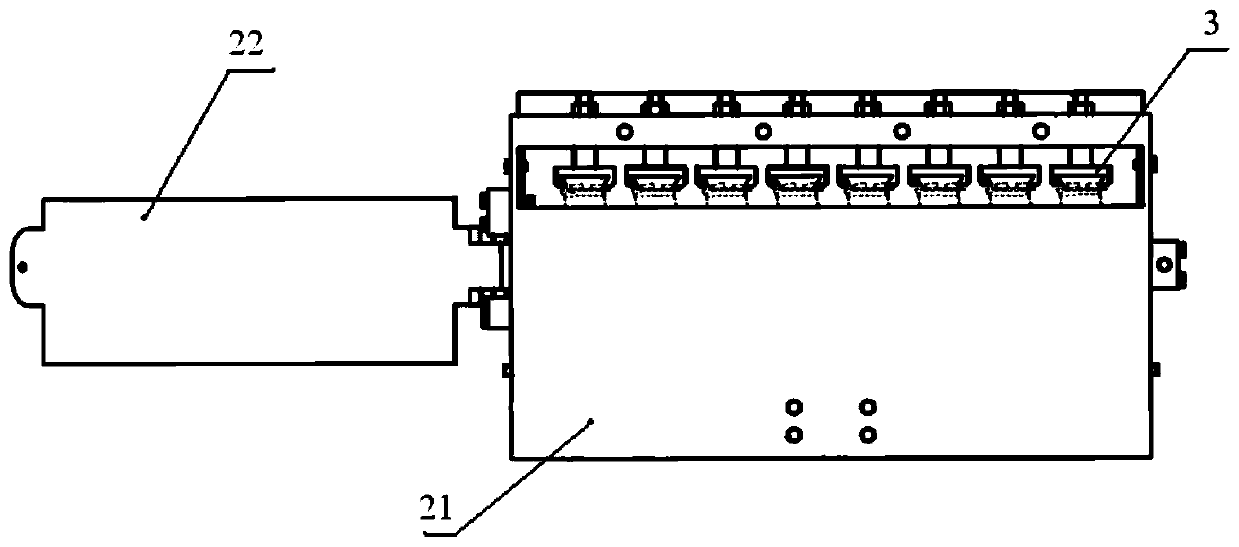

[0043] Blade spray protection fixture, including frame body 2, glue, slider 3, and pusher 4, the glue is located in the slot of slider 3, the slot of slider 3 faces the pusher 4, there are 8 pieces of glue and slider 3 respectively; the frame body 2. It includes a main frame 21 and a pressure plate 22. The main frame 21 and the pressure plate 22 are connected by shafts and positioned by screws. The pressure plate 22 is provided with a stopper 23, and the main frame 21 is provided with an upper stopper on which the slider 3 is installed and fixed. The upper stopper is threadedly connected with the slide block 3, and the main frame 21 is provided with a chute; the pusher 4 includes a push plate 41, which is connected to one end of the screw rod, and the other end of the screw rod is connected to a nut sleeve, and the nut sleeve is fixed on the main frame through the support. On the frame 21 , the nut cover is connected with the torsion bar by screws, and the torsion bar is rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com