An auxiliary mold for side positioning

A mold and gear technology, applied in the field of auxiliary molds for side positioning, can solve the problems of difficult batch stamping production, affecting molding quality, and low work efficiency, and achieve the effect of improving utilization rate, simple structure, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

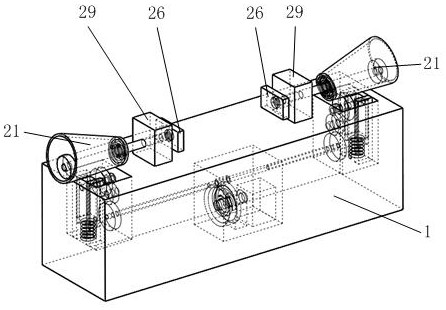

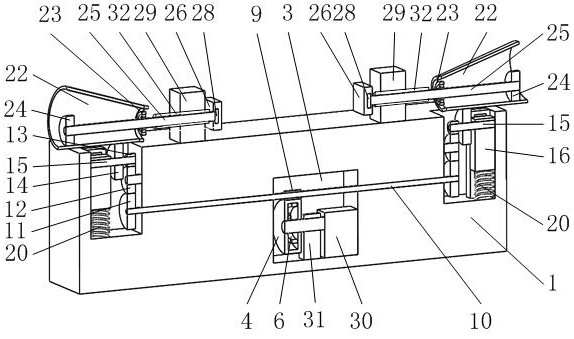

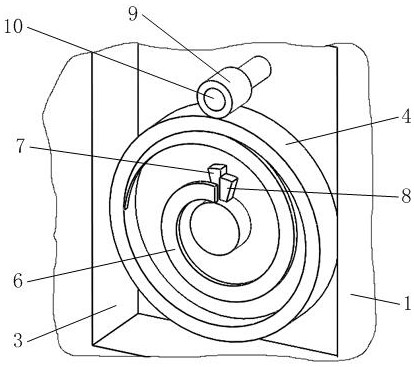

[0033] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0034] Such as figure 1 , 2 As shown, it includes a base 1, a gear A4, a scroll spring 6, a gear E13, a friction wheel 14, a shaft B15, a slider 16, a pressure spring 20, a clamping mechanism 21, and an electric drive module 30. figure 2 , 3 As shown in , 10, an electric drive module 30 is installed in the transmission groove B3 on the base 1, a gear A4 and a scroll spring 6 are installed on the output shaft of the electric drive module 30, and the scroll spring 6 resets the movement of the gear A4; Such as image 3 As shown, the block A7 installed on the side wall of the gear A4 cooperates with the block B8 installed on the output shaft of the electric drive module 30; fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com