A kind of reinforced concrete I-beam construction formwork and its operation method

A technology of reinforced concrete and I-beams, applied in the direction of manufacturing tools, mold fixtures, mold auxiliary parts, etc., can solve the problems of wasting time, troublesome installation, etc., and achieve the effect of easy disassembly and installation, and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

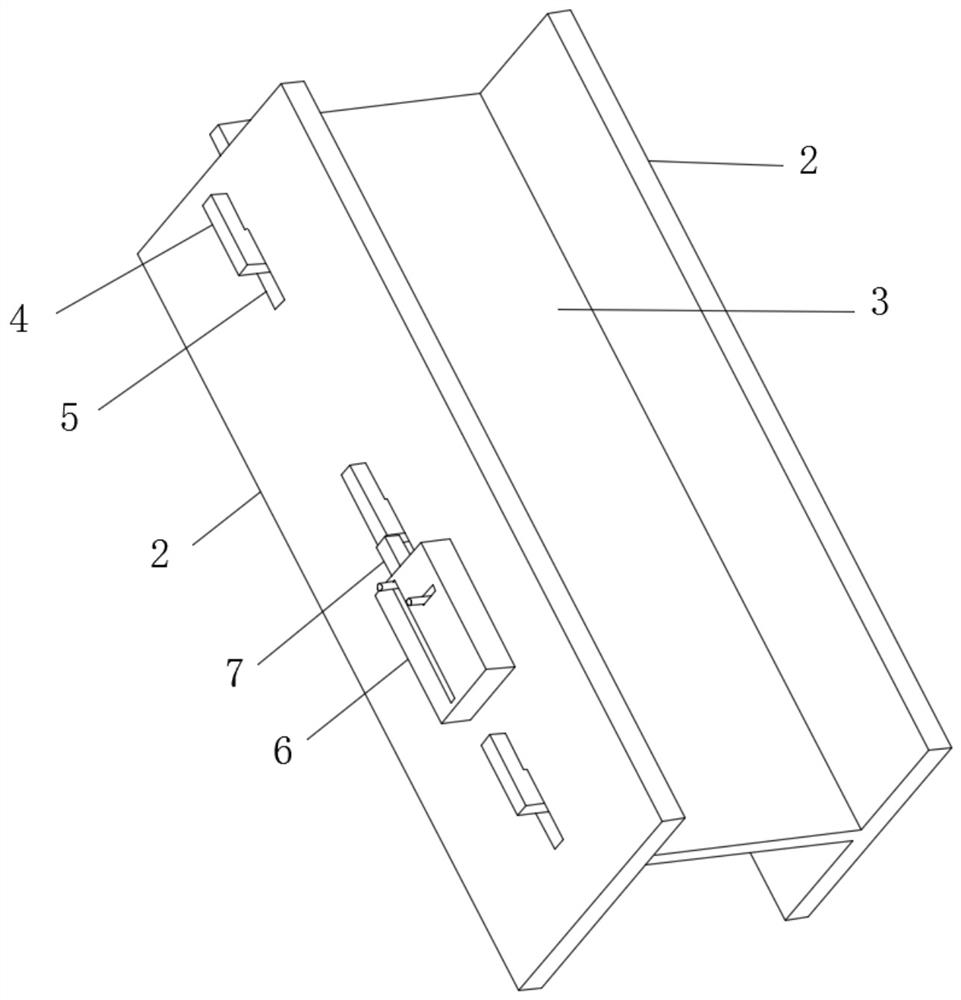

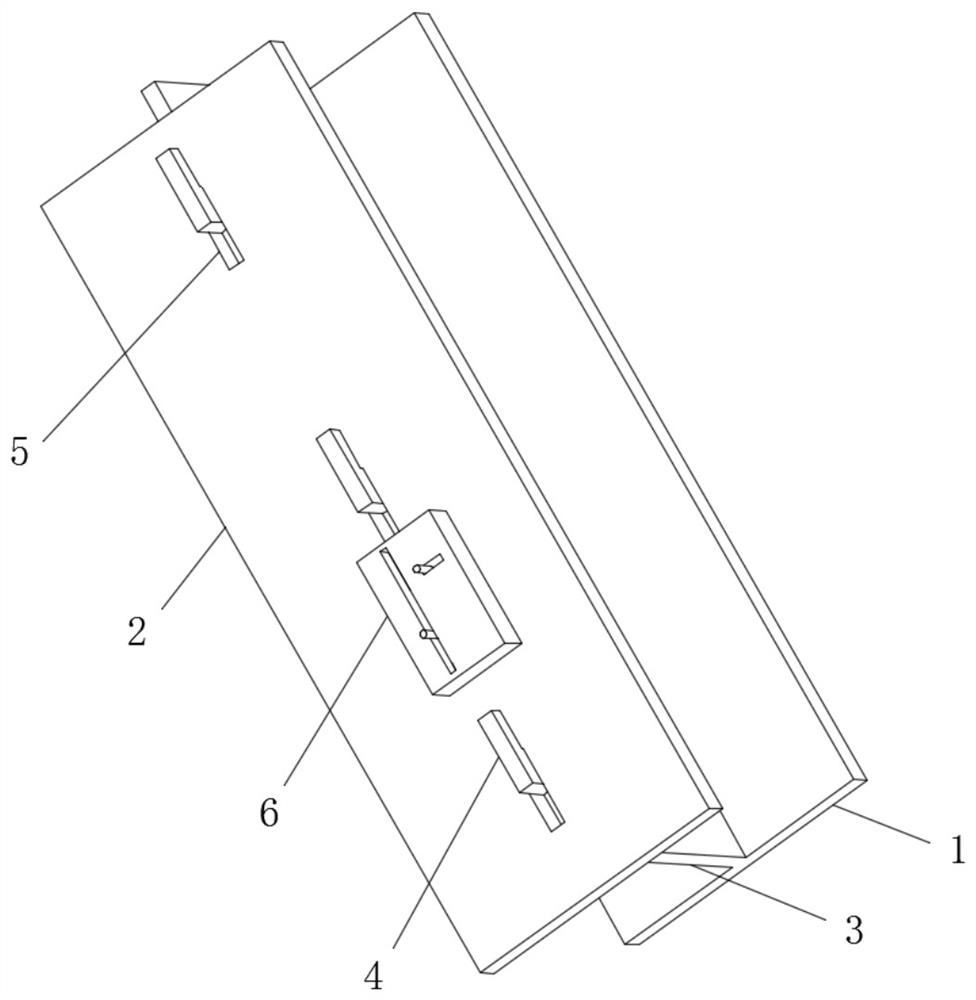

[0029] refer to Figure 1-4 , a reinforced concrete I-beam construction formwork, including an upper baffle 1, a lower baffle 2 and a web 3, the upper baffle 1 and the web 3 are perpendicular to each other and integrally formed, and the end of the web 3 is far away from the upper baffle 1 A block 4 is connected, and a slot 5 matching the block 4 is drilled on the side wall of the lower baffle 2. The web 3 is slidably connected with the lower baffle 2 through the block 4, and the side wall of the lower baffle 2 is connected with Fastening box 6, the inside of fastening box 6 is excavated with the first chute 10 parallel to the card slot 5, the first chute 10 is slidingly connected with locking block 7, and the locking block 7 is placed in the first chute 10 A first spring 11 is connected between one end and the groove wall of the first chute 10, and a limit assembly is also connected inside the fastening box 6. Before pouring concrete, the web 3 is inserted into the lower baffl...

Embodiment 2

[0031] refer to Figure 5 , a reinforced concrete I-beam construction template, which is basically the same as Example 1, the difference is that a second chute 9 perpendicular to the first chute 10 is excavated inside the fastening box 6, and the first chute 10 communicates with the second chute 9.

[0032] The limit assembly includes a limit block 8 and a second spring 12, the limit block 8 is slidably connected in the second chute 9, and the second spring 12 is connected to one end of the limit block 8 placed in the second chute 9 and the second Between the 9 groove walls of the chute.

[0033] When the locking block 7 is pulled, the locking block 7 pushes up the limiting block 8 and slides upward in the second chute 9, and when the locking block 7 and the clamping block 4 are in contact, the limiting block 8 is under the force of the second spring 12 Reset blocks the locking block 7 to prevent it from slipping back. When the module needs to be disassembled, pull the limit...

Embodiment 3

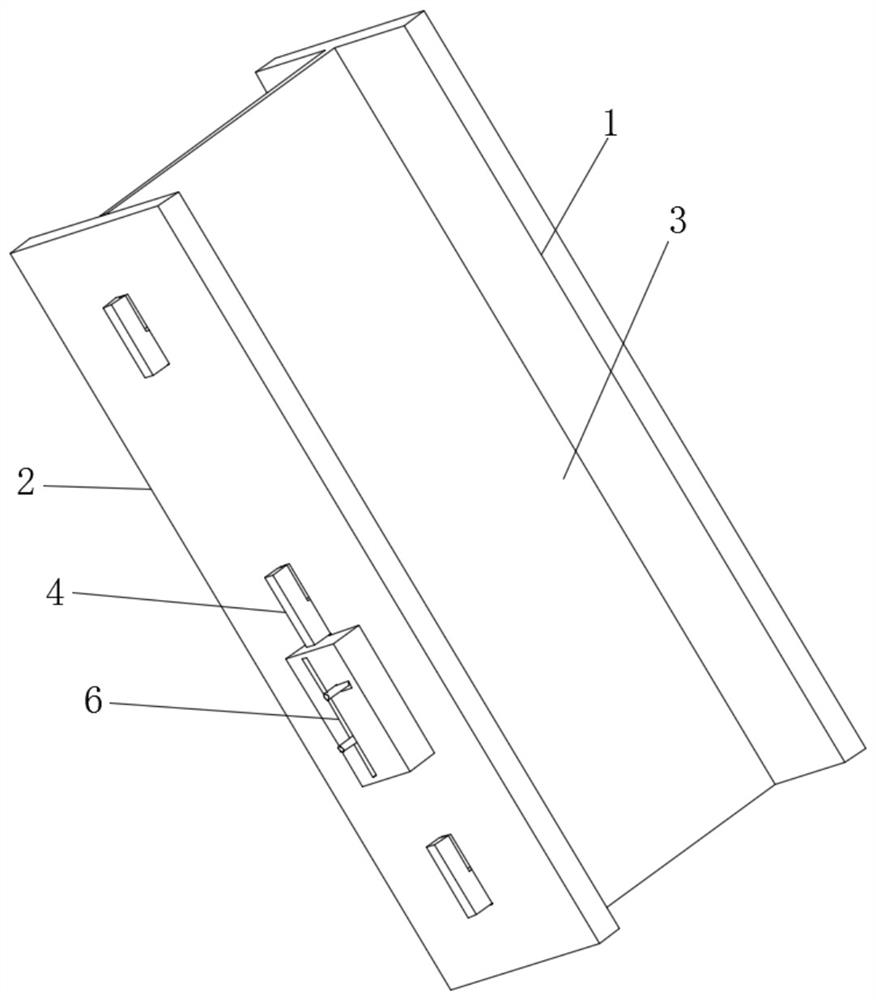

[0035] refer to Figure 4 , a reinforced concrete I-beam construction template, which is basically the same as Embodiment 2, and furthermore, the clamping block 4 is L-shaped, and the L-shaped clamping block 4 is convenient for the clamping block 4 and the clamping groove 5 to be able to slide and displace and clamp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com