Communication pipe processing die and processing technology thereof

A technology for processing molds and communication pipes, which is applied in the field of communication pipe processing molds and its processing technology, can solve the problems of uneven thickness of pipes, difficult and stable mold assembly and fixation, and achieve good firmness and stability, good heating range and effect , producing viable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

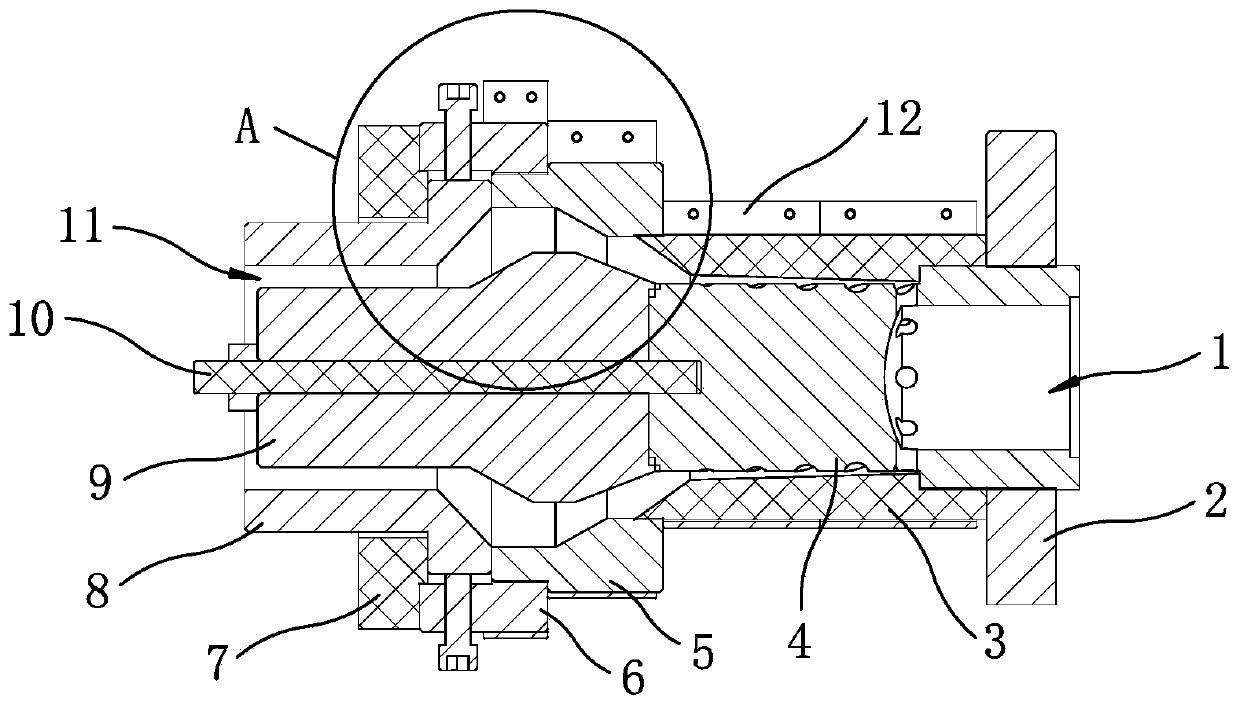

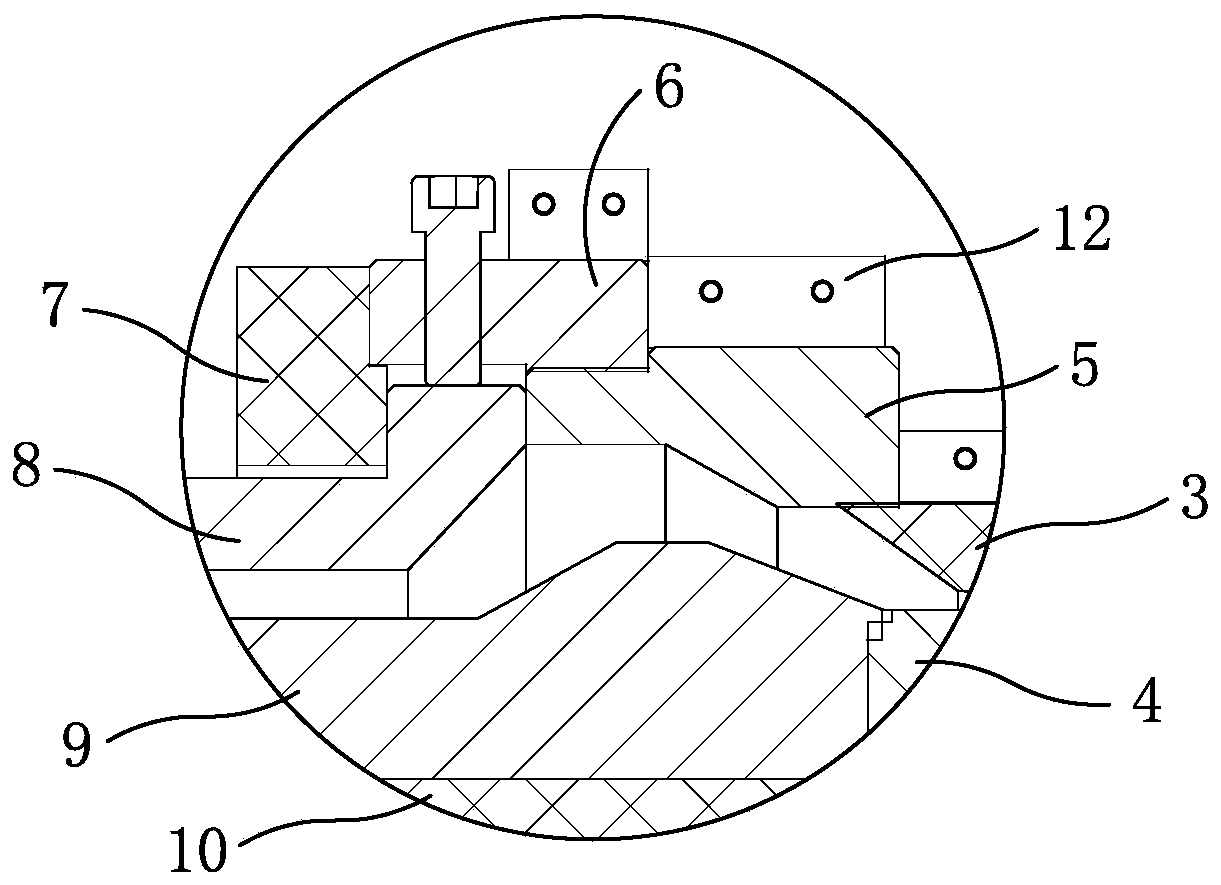

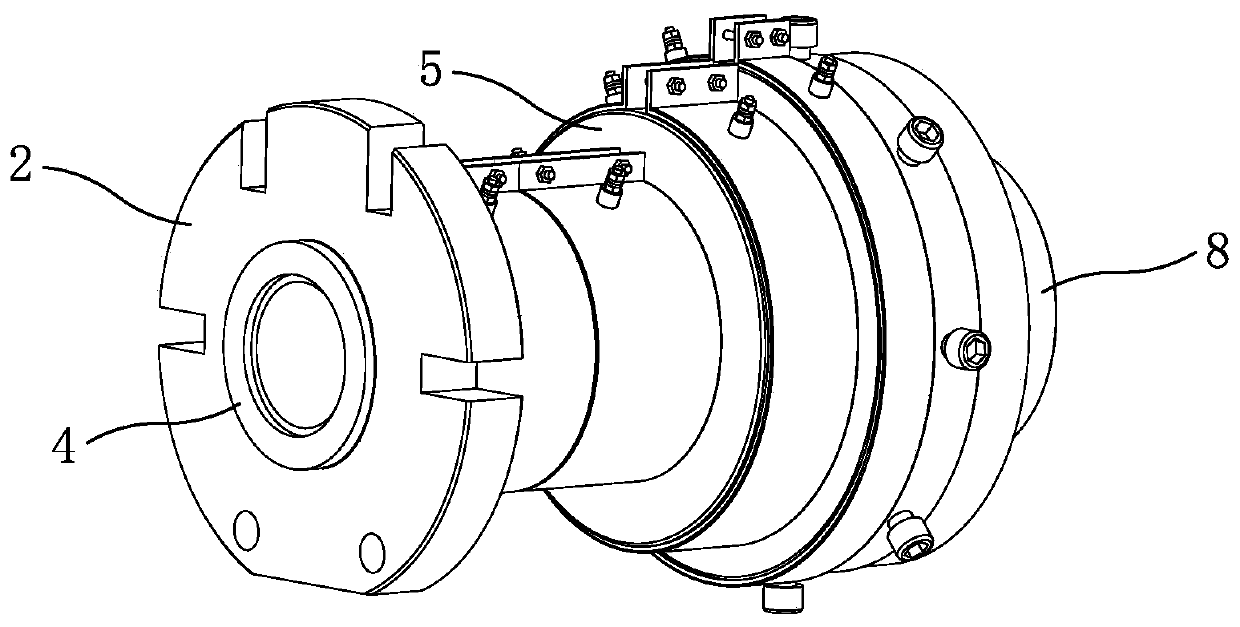

[0021] Now in conjunction with the accompanying drawings, the structure and use of the present invention will be further described. Such as Figure 1-Figure 7 As shown, the tube body of the mold includes a mounting ring 2, a screw outer cavity 3, an adjustment core rear end seal ring 5, an adjustment ring 6, an adjustment core front end seal ring 7, a floating discharge ring 8, and the outer diameter of the tube corresponding to The heating ring 12 and the extruding screw provided with the inner diameter of the pipe, the installation ring, the outer cavity of the screw, the sealing ring at the rear end of the adjusting core, the adjusting ring, the sealing ring at the front end of the adjusting core, and the floating discharge ring are sequentially fitted together to form the pipe body. The installation ring of the pipe body is fixedly set on the outer diameter of the ring opening of the feed and diversion screw at the joint between the feed and diversion screw 4 and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com