Ultrasonic assisted indexable end mill blade one-way pressing device

An ultrasonic-assisted, one-way pressing technology, applied in presses, manufacturing tools, material forming presses, etc., can solve the complex shape of indexable end mill blades, aggravate the uneven density distribution of green parts, and make green parts Problems such as uneven density distribution, to achieve the effect of uniform force, easy removal, and uniform ultrasonic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

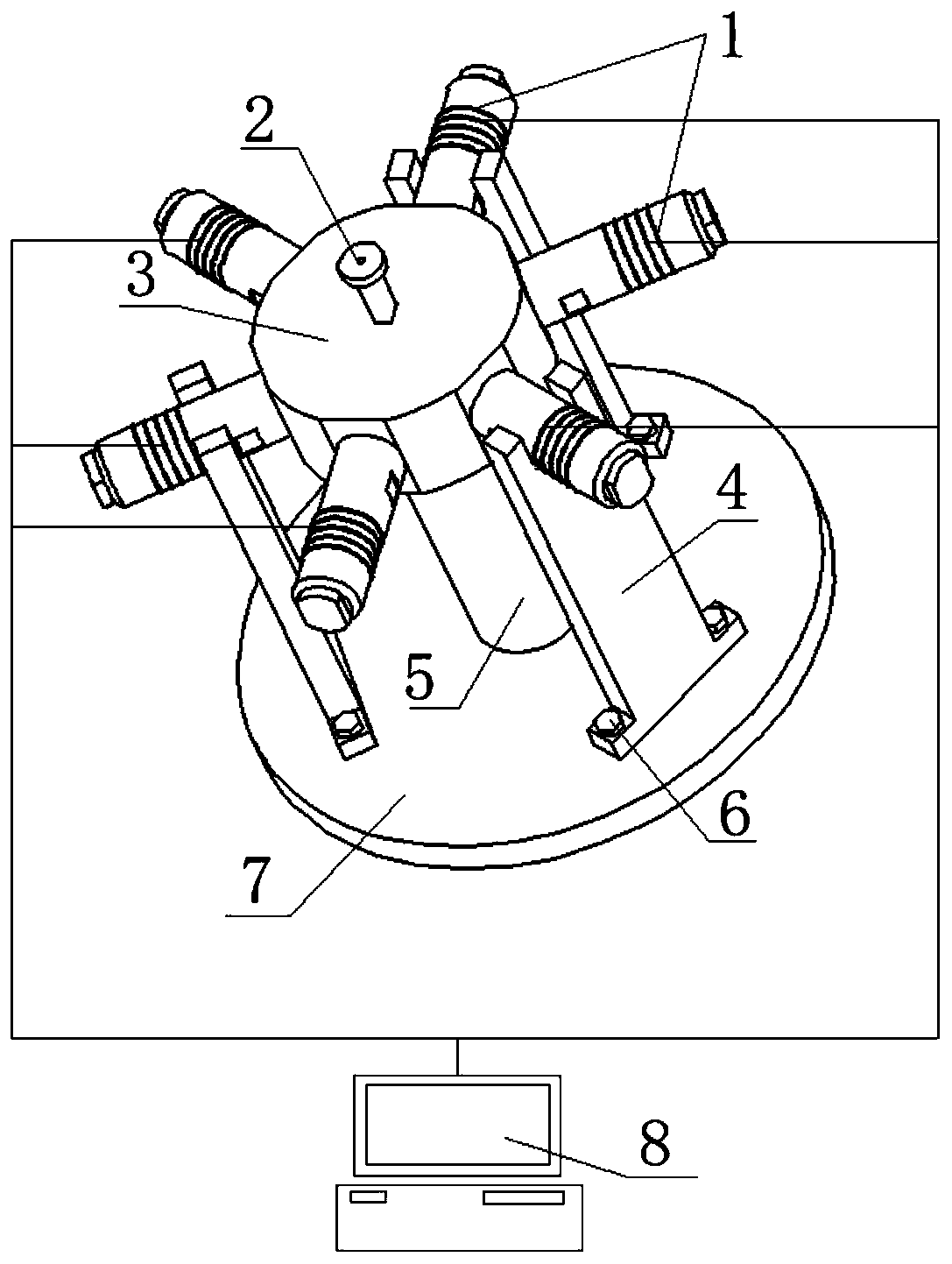

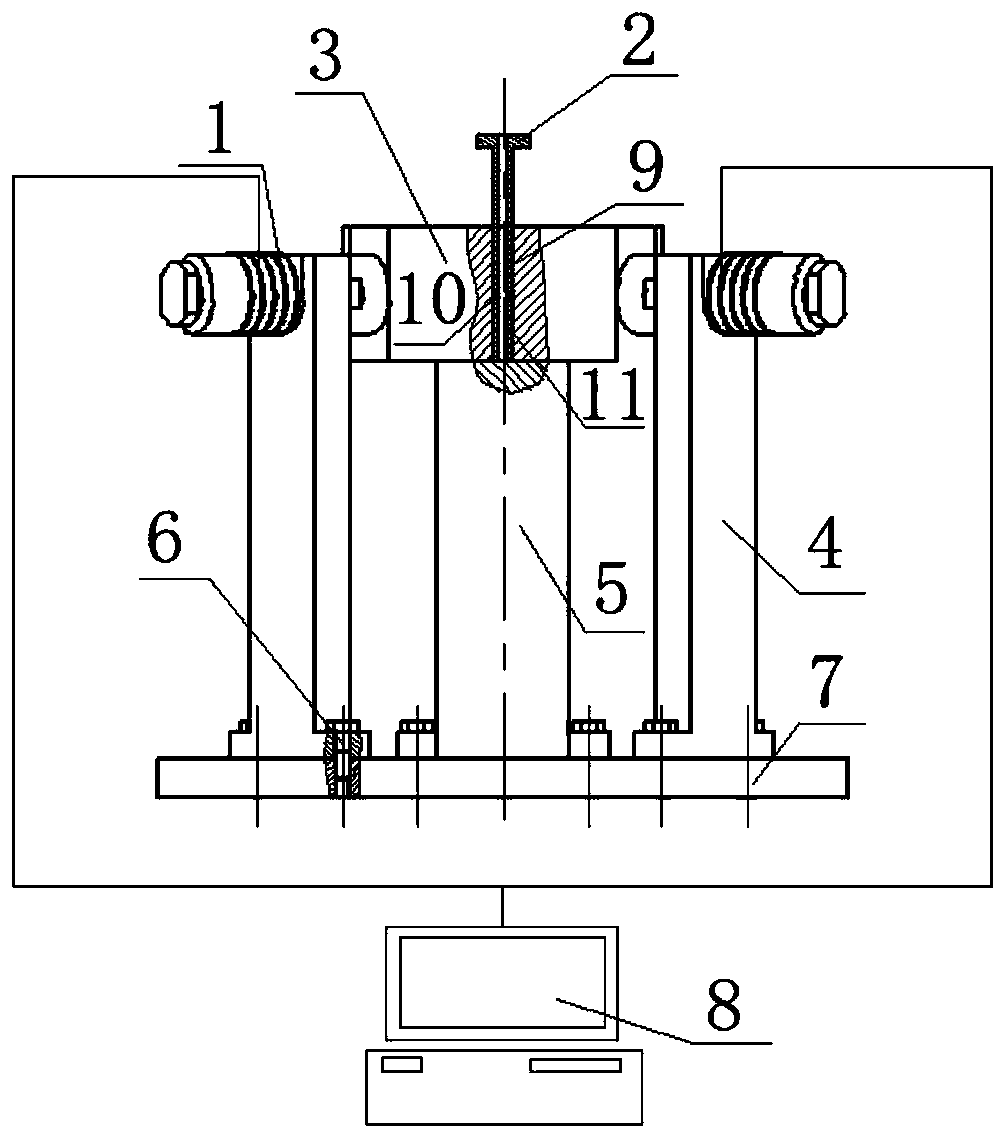

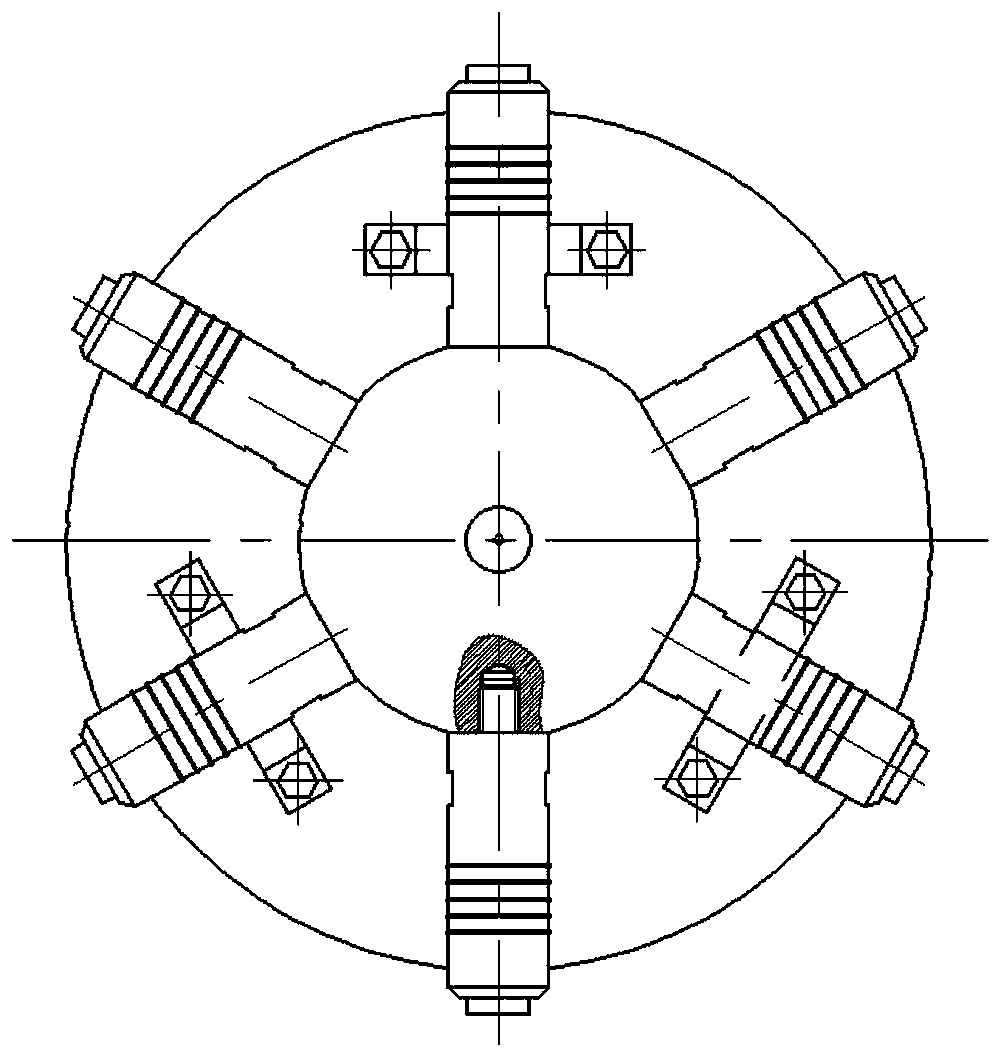

[0043] Such as Figure 1-8 As shown, an ultrasonic assisted indexable milling cutter blade unidirectional pressing device includes an ultrasonic assisted unidirectional pressing mold and an ultrasonic generator 8; the ultrasonic unidirectional pressing mold includes an ultrasonic transducer 1, an upper pressing head 2, Mold 3, transducer fixing frame 4, mold support block 5, base connecting bolt 6, base 7, core post 9, milling cutter blade blank 10, and pressing head 11.

[0044] Such as Figure 8As shown, the head of the ultrasonic transducer 1 is threaded, and is fastened to the mold 3 through threaded connection. The six ultrasonic transducers 1 are centrally distributed and evenly distributed on the six corners of the mold 3, and the included angle between adjacent ultrasonic transducers 1 is 60 degrees. Wherein, three non-adjacent ultrasonic transducers 1 are placed on the opening of the transducer fixing frame 4 for fixing the horizontal displacement of the mould. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com