Spiral elevator based on planet roller screw

A technology of screw elevator and planetary roller, applied in the direction of lifting device, etc., can solve the problems of low transmission efficiency, easy wear of parts, high friction, etc., and achieve the effects of stable transmission, cleanliness, and large bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

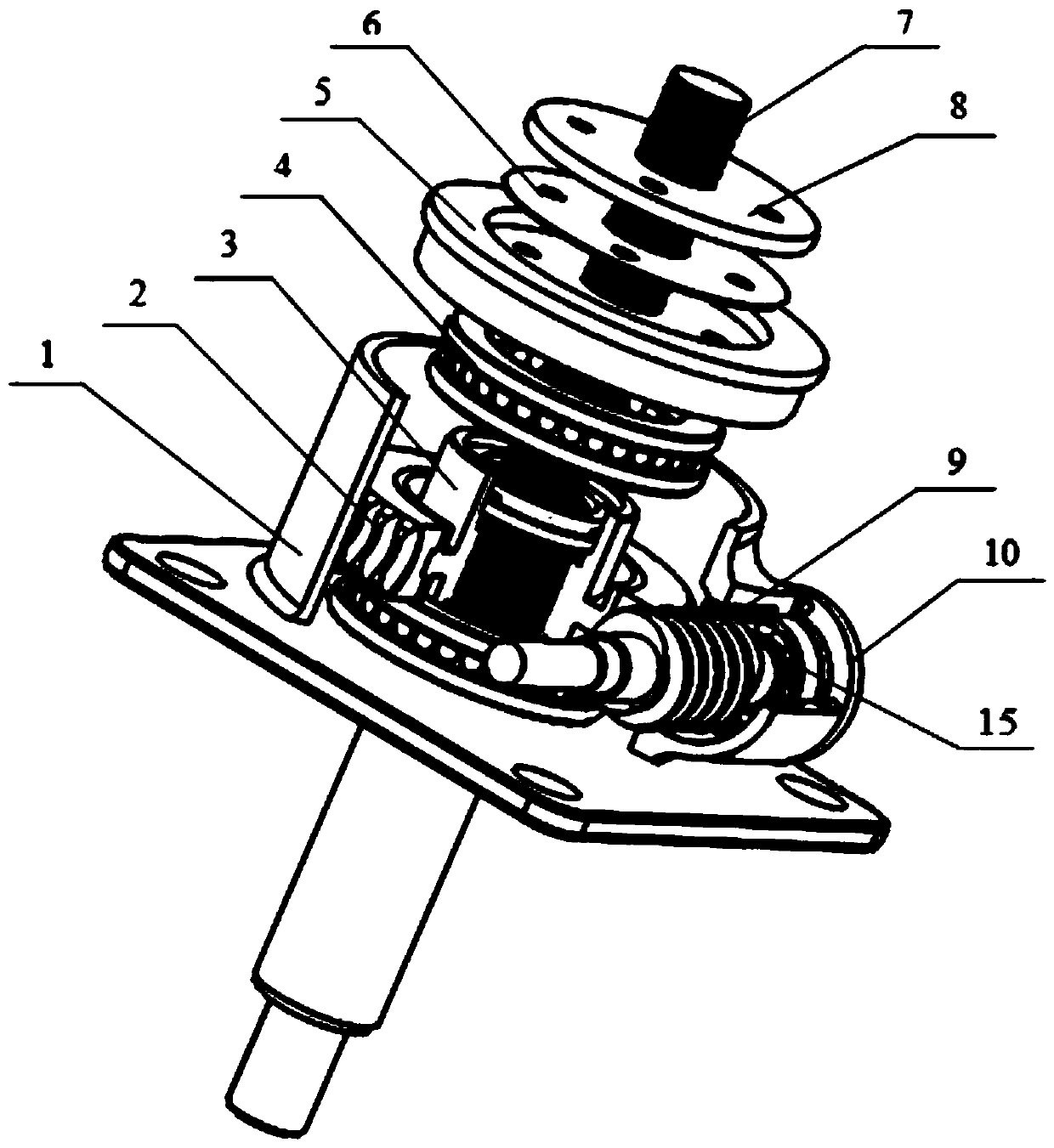

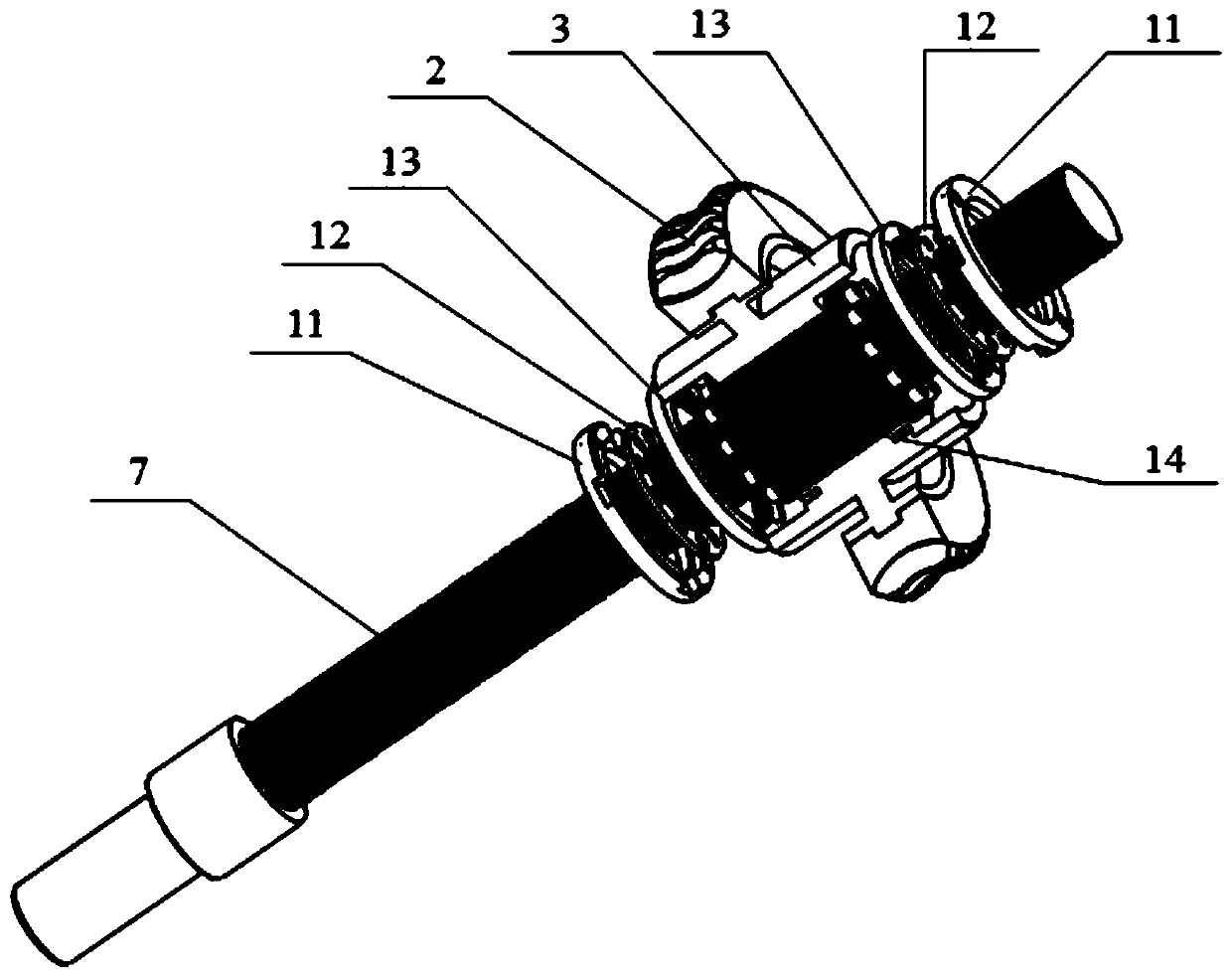

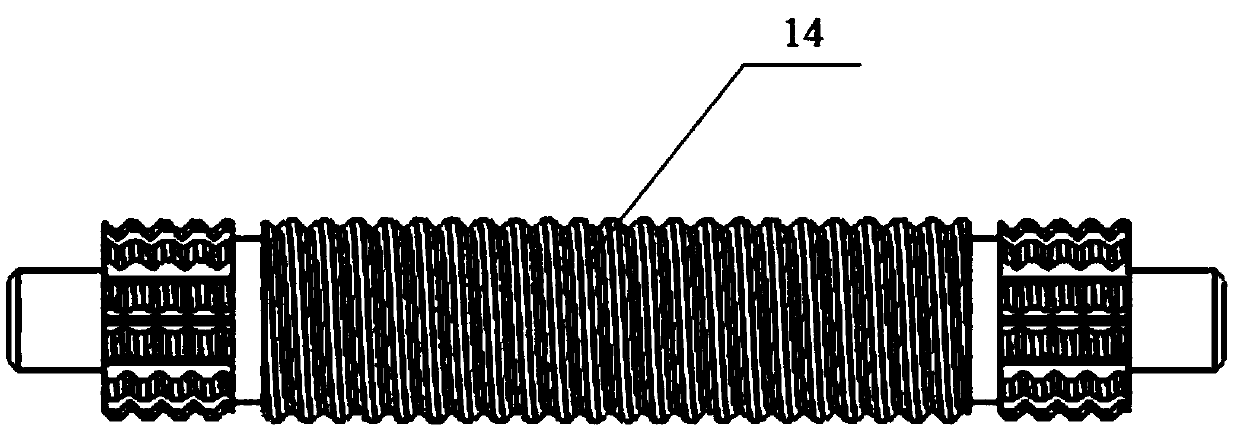

[0035]When working, the motor drives the worm shaft 9 to rotate through the flat key, and the worm 9 transmits the torque to the worm wheel 2, so that the worm wheel 2 and the nut 3 rotate together. Since the position of the worm wheel 2 and the worm 9 is fixed in the box body 1, the nut 3 can only Rotary motion, no axial movement. Driven by the nut 3, the roller 14 performs rotational motion around its own axis and planetary motion around the axis of the lead screw 7 at the same time. Since the lead screw 7 is axially fixed, the roller 14 can only drive the lead screw 7 to move along the axis, thereby Realize the lifting work of the screw jack.

[0036] The main advantages of this embodiment are: compared with the traditional trapezoidal screw drive, the planetary roller screw has high efficiency, long life, and strong impact resistance; compared with the ball screw drive, it has higher efficiency and higher load capacity. Larger, less noise, stronger impact resistance, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com