60 kg/m steel rail No.9 alloy steel inlaid-type fixed width quasi-diamond cross turnout and design method thereof

A design method and technology of alloy steel, applied in the field of rail transit, can solve the problems that the cross equipment cannot meet the fast and large transportation volume, the strength of the connection between the rail and the wooden sleeper is weak, and it is difficult to meet the safety requirements of the line, etc. The effect of improving the efficiency of the shunting operation and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

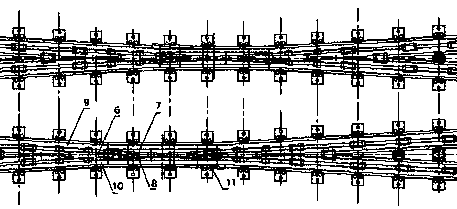

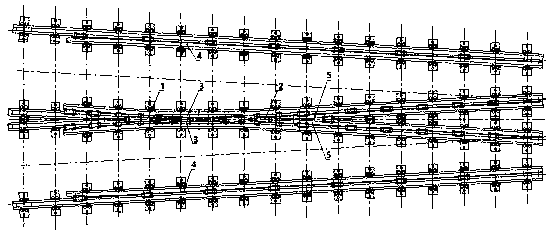

[0026] Such as Figure 1-2 As shown, a 60kg / m rail No. 9 alloy steel mosaic fixed wide quasi-rhombic crossing turnout includes acute angle frogs and obtuse angle frogs; the obtuse angle frogs are inlaid wing rail type alloy steel combined obtuse angle frogs, The acute-angle frog is also an inlaid wing-rail type alloy steel combined frog; the acute-angle frog includes a sharp-angle frog forged alloy steel core rail 1, a forged alloy steel acute-angle frog core rail guard rail 2, and an acute-angle frog Wing rail insert 3, acute angle frog guard rail 4, acute angle frog inner guard rail 5, the obtuse angle frog includes obtuse angle frog forged alloy steel core rail 6, obtuse angle frog guard rail insert 7, obtuse angle frog Wing rail insert 8, obtuse frog guard rail 9, obtuse frog wing rail 10, obtuse frog rim guard rail 11.

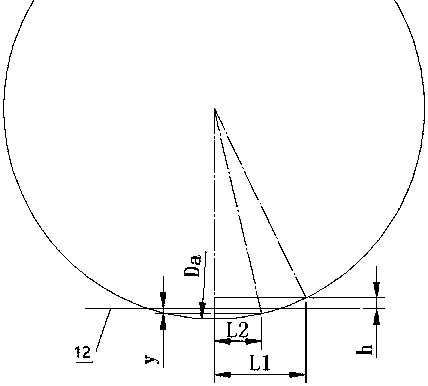

[0027] For fixed-type sharp-angle frogs, there is a gauge line interruption within the range from the throat of the frog to the theoretical tip, that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com