Bilateral plastering device for flue or air shaft and plastering method

A technology of flue and air shaft, which is applied in the direction of construction and building structure, can solve the problems of low construction efficiency, difficulty, missing plastering, etc., and achieve the effect of good plastering effect, low production cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

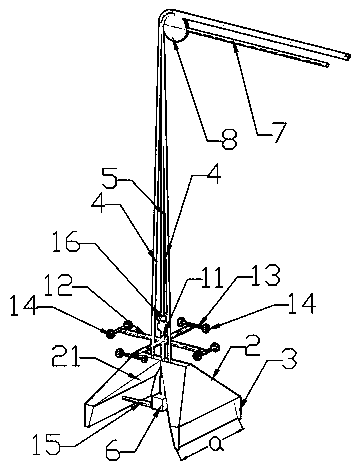

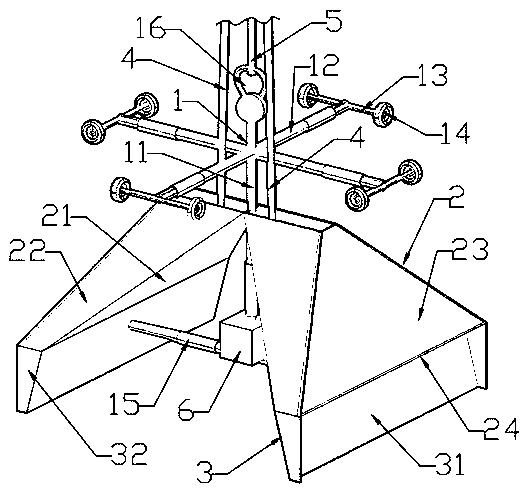

[0025] Such as figure 1 , figure 2As shown, the double-sided plastering device for flue or air shaft provided by this embodiment includes a support frame 1 that can be supported on at least two opposite inner walls of a narrow space and can slide up and down under the pull of an external force. Both opposite sides of the support frame 1 are fixedly equipped with a hopper 2 whose lower end is inclined outward, and the hopper 2 is a box-shaped body with a discharge port 24 at the lower end; Feed pipe 4, the upper ends of the two flexible concrete feed pipes 4 communicate with the discharge port of the mixer, and the lower ends extend into the corresponding hoppers 2; the lower ends of each hopper 2 are equipped with ash The shovel 3, the ash shovel 3 is shovel-shaped, and is composed of a shovel plate 31 installed on the inside of the discharge port 24 of the hopper 2 and baffles 32 arranged on both sides of the shovel plate 31; the concrete enters the two sides through the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com