A pipe gallery anti-seismic energy buffering support structure

A support structure and pipe gallery technology, applied in the direction of pipe supports, springs/shock absorbers, pipes/pipe joints/pipe fittings, etc., can solve the problems of pipe gallery transmission vibration and poor seismic performance, so as to reduce the impact and strengthen the buffering effect , the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

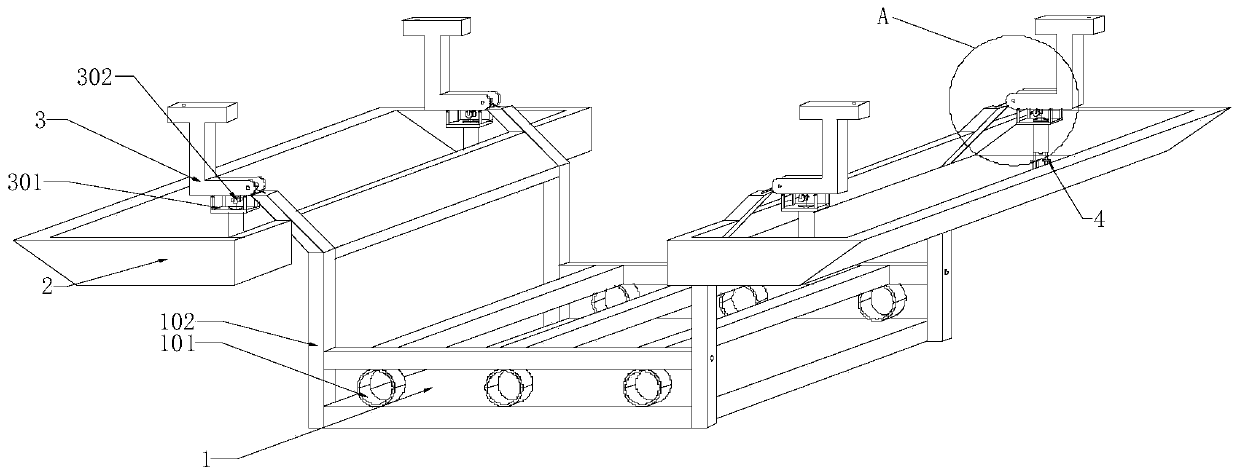

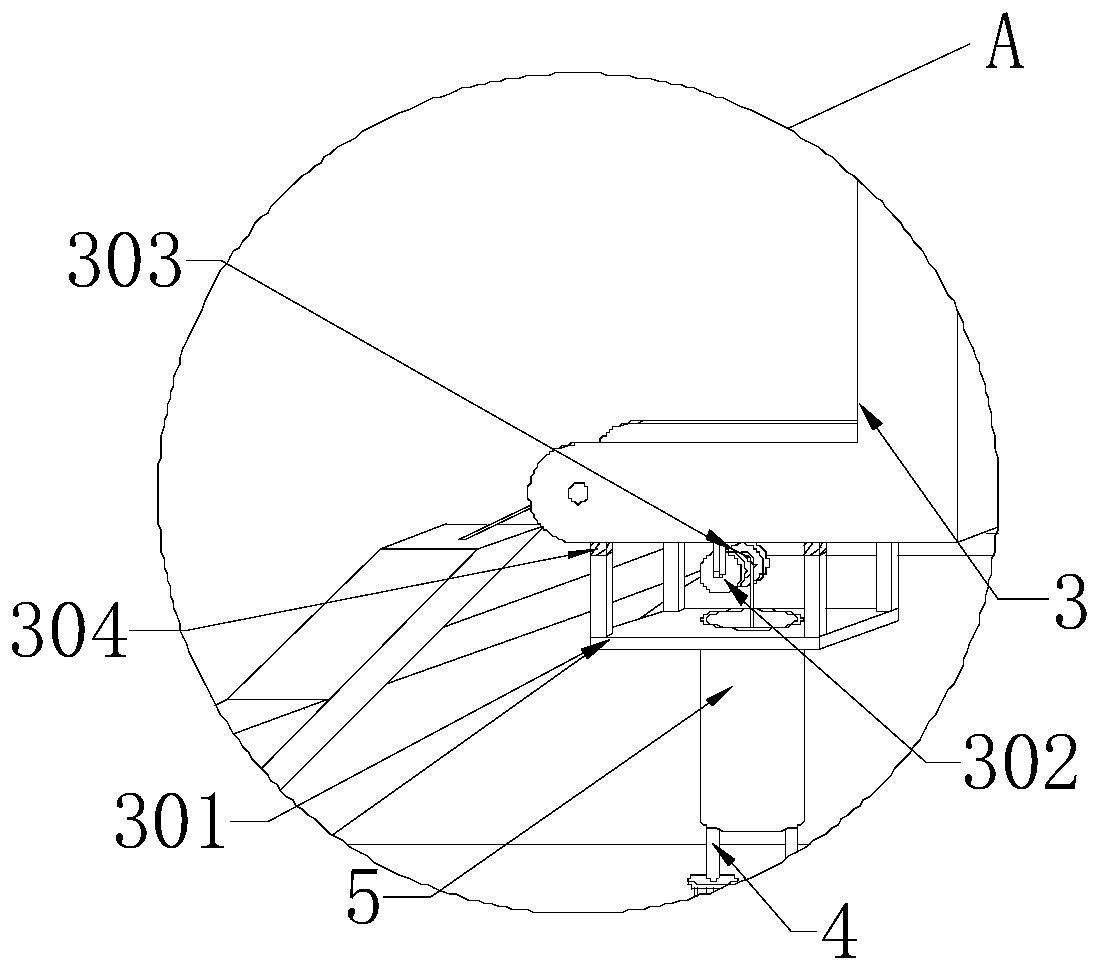

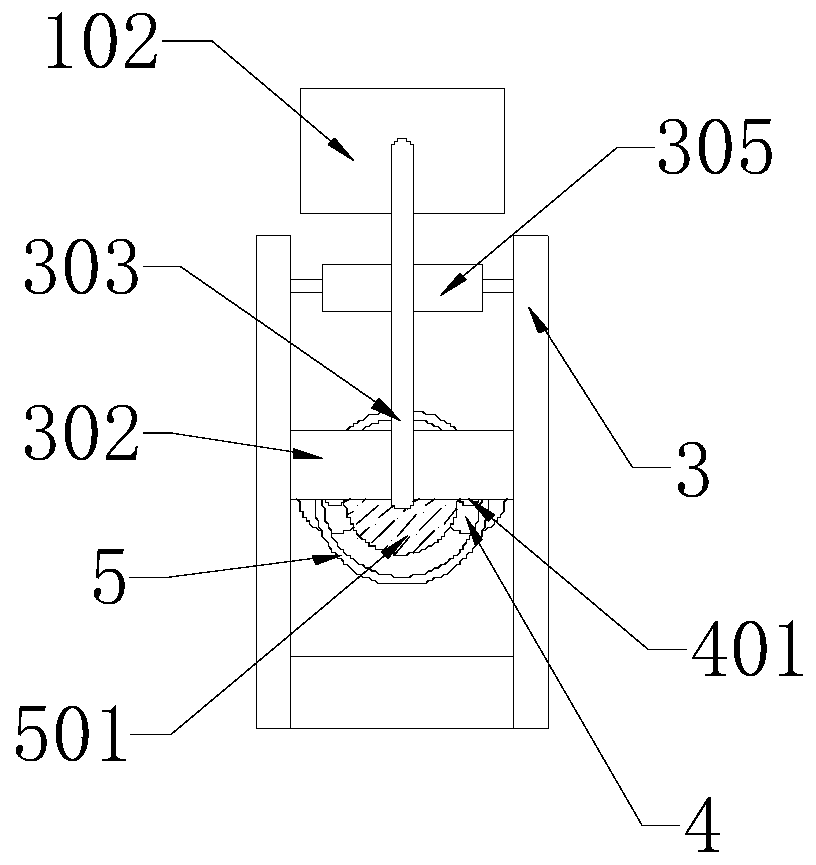

[0033] The present invention provides an anti-seismic energy buffering support structure for a pipe gallery, which includes a supporting plate 1, a hoop 101, a side column 102, a box-shaped body 2, a top frame 3, a connecting platform 301, a second pulley 302, a traction cable 303, and a spring block 304, the first pulley 305, the force guide branch 4, the connecting ball 401, the support cylinder 5 and the buffer sheet 501, the top surface of the support plate 1 is fixedly connected with a plurality of hoops 101, and the four-corner top surface of the support plate 1 is fixedly connected with the side columns 102 , the side column 102 away from the supporting plate 1 side is fixedly connected with a box-shaped body 2, in this embodiment the boxed body 2 is used to hold pure water, the top of the side column 102 is fixedly connected to the top frame 3, and the top frame 3 is connected to The platforms 301 are connected by a spring block 304, the top frame 3 is movably provided ...

Embodiment 2

[0041] The difference between embodiment 2 and embodiment 1 is that in embodiment 2, the box-shaped body 2 contains a non-volatile solvent, such as brine.

Embodiment 3

[0043] Embodiment 3 discloses a method for constructing a pipe gallery anti-seismic energy buffering support structure, including the following steps:

[0044] Fix the top frame 3 on the top of the pipe gallery, and pass the pipeline through the hoop 101;

[0045] The traction cable 303 fixed on the top surface of the side column 102 goes around the first pulley 305 and the second pulley 302, and the buffer piece 501 is placed on the end section of the traction cable 303, and the connecting ball 401 is stuck between the buffer pieces 501 at the same time ;

[0046] Fix the buffer piece 501 to the end section of the traction cable 303, and at the same time pass the connecting table 301 through the buffer piece 501, so that the connecting ball 401 and the buffer piece 501 are placed in the support cylinder 5;

[0047] The top surface of the spring block 304 is fixed on the bottom surface of the top frame 3;

[0048] Liquid is injected into the box-shaped body 2 .

[0049] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com