Double-catalyst coating louver-type heat collecting wall and using method thereof

A dual-catalyst, louver-type technology, applied in the field of double-catalyst-coated louver-type heat collecting walls, can solve the problems of single function of heat collecting walls and inability to adapt to various working modes, so as to increase and reduce indoor heat load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

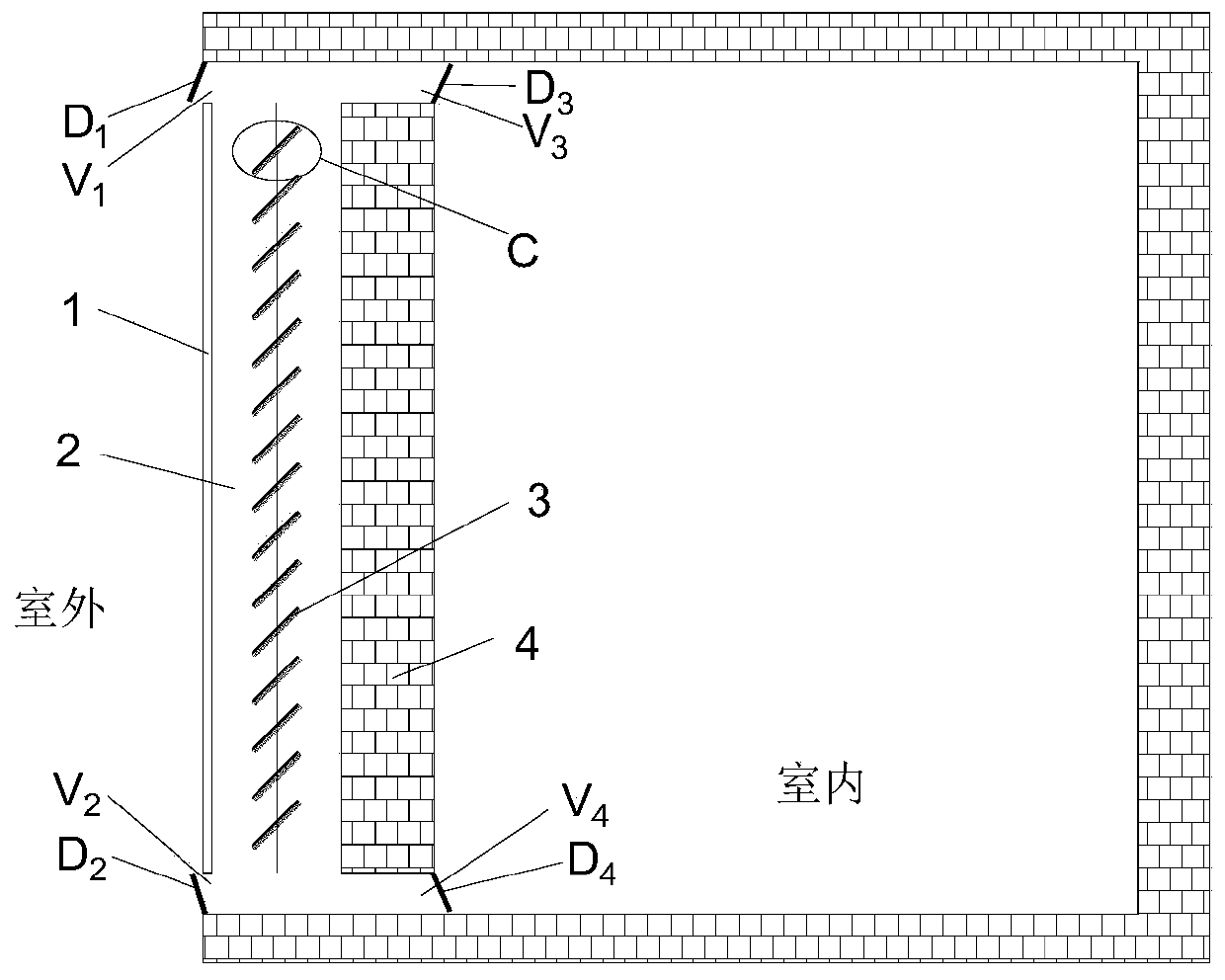

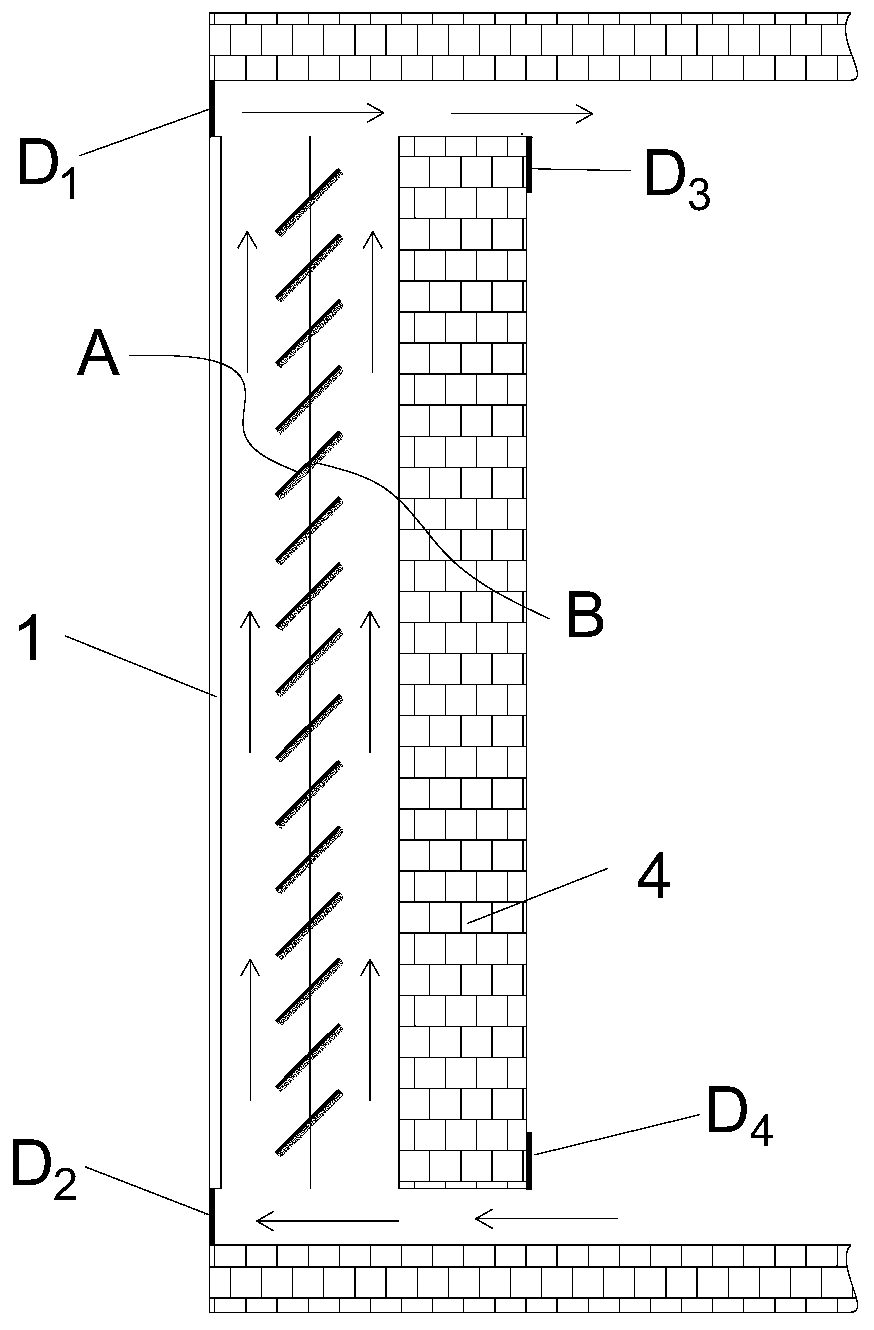

[0033] Such as figure 1 , 2 As shown, the double-catalyst-coated louver-type heat collecting wall in this embodiment includes light-transmitting glass 1, venetian blind 3, and heat-collecting heat-storage wall 4 arranged in parallel in sequence; It is the air channel 2, and the upper and lower ends of the light-transmitting glass 1 are provided with a first outdoor vent V1, a second outdoor vent V2, and a first outdoor vent V1 and a second outdoor vent V2 to open and close. The outdoor baffle D1 and the second outdoor baffle D2; the upper and lower ends of the heat collecting and storage wall 4 are provided with a first indoor vent V3 and a second indoor vent V4, and realize the first indoor vent V3 and the second indoor ventilation The first indoor baffle D3 and the second indoor baffle D4 that open and close the port V4, the first outdoor vent V1 and the first indoor vent V3 are on the same horizontal line, the second outdoor vent V2 and the second indoor vent V4 is on the...

Embodiment 2

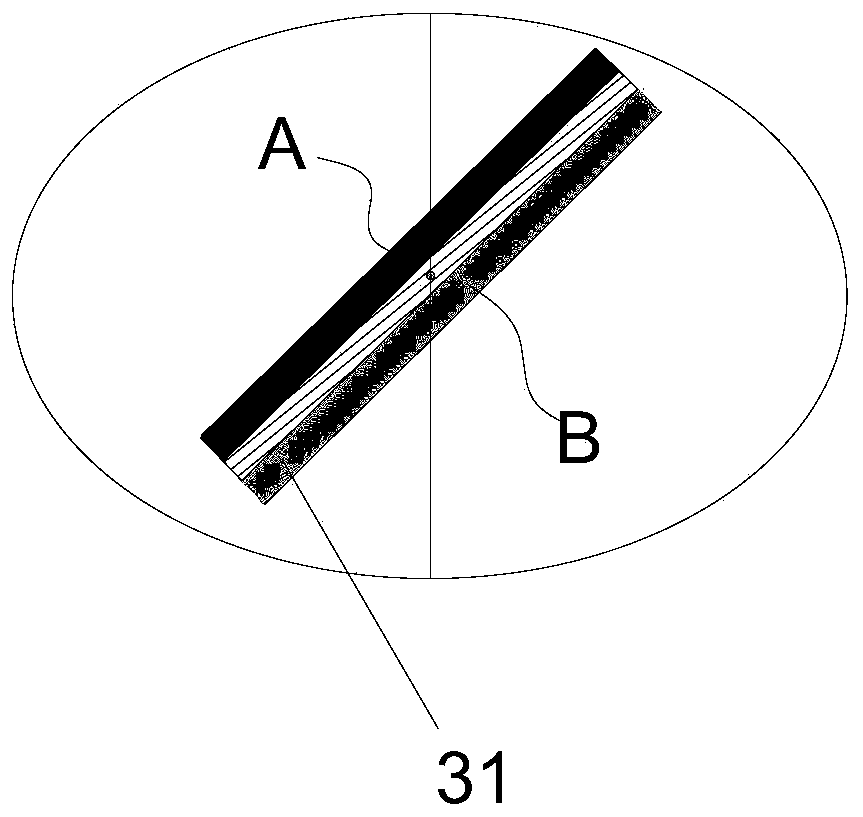

[0038] In this embodiment, on the basis of Embodiment 1, the materials of the thermal catalytic layer are noble metal catalysts (Pt, Au, Rh, Pd), transition metal catalysts (CuO, MnOx, CeO 2 ) in one or more combinations, select MnOx-CeO2, MnOx-CeO in the present embodiment 2 It is black in color, and its absorptivity in the sunlight band is 0.94. The thermal catalytic layer has good heat collection efficiency, and it will be stimulated to oxidize and degrade organic pollutants at a certain temperature.

[0039] The photocatalyst layer is made of one or more combinations of titanium dioxide, zinc oxide, tin oxide, zirconium dioxide and cadmium sulfide. Among them, the photocatalyst material is preferably white titanium dioxide, because of its strong oxidizing ability, stable and non-toxic chemical properties, it has become the most popular nano photocatalyst material in the world, TiO 2 It can degrade organic pollutants under the excitation of ultraviolet light, and the photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com