Cement mortar fluidity tester

A cement mortar and fluidity technology, applied in the directions of flow characteristics, instruments, measuring devices, etc., can solve the problems of not being able to accurately and quickly find the diameter of the mortar round cake, affecting the experiment rate, and unable to quickly clean the tabletop, saving manpower and speeding up the experiment. process, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

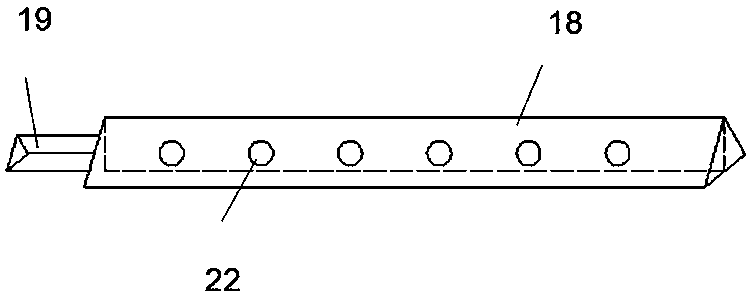

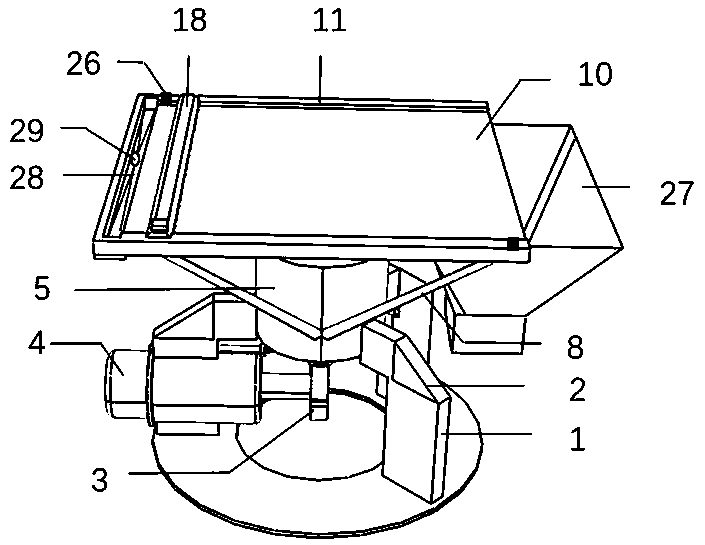

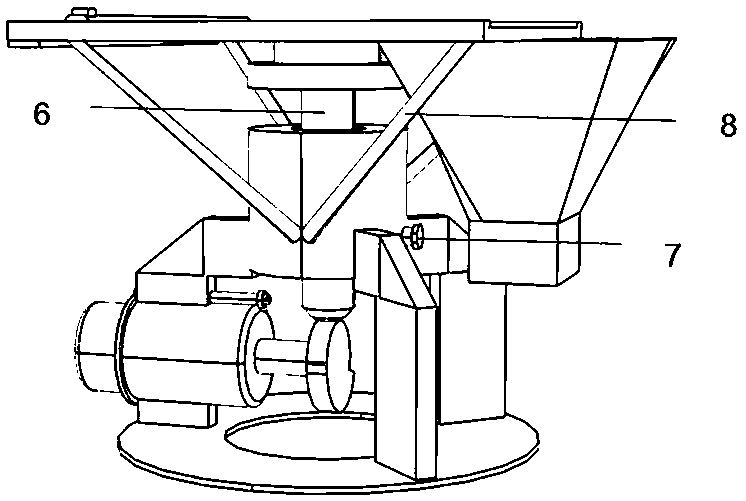

[0025] A cement mortar fluidity tester, comprising a frame base 1, a rib plate 2, a cam 3, a first motor 4, a sleeve 5, a push rod 6, a limit screw 7, a support rod 8, a fixed desktop 9, and waterproof rubber 10. Waterproof edge 11, jumping table top 12, conveyor belt 13, second motor 14, driving wheel 15, driven wheel 16, protective cover 17, cleaning brush 18, outrigger rod 19, water outlet 20, slider 21, air outlet 22. Water inlet pipe 23, fan 24, electric heating wire 25, infrared distance measuring device 26, feeding funnel 27, drainage groove 28, drainage pipe 29, hydraulic booster pump, water storage device, first valve, cylinder, second valve. It can be seen from the figure that the present invention is mainly divided into two parts: 1. Jumping table, 2. Cleaning measurement, the fixed connection in the present invention is welding or bolt connection.

[0026] like figure 1 , 2 As shown, the jumping table part includes a frame base 1 , a rib plate 2 , a cam 3 , a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com