Breathing ammonia gas sensor based on polyaniline/semiconductor metal oxide nano composite film and preparation method thereof

An ammonia gas sensor and nanocomposite technology, which is applied to instruments, scientific instruments, measuring devices, etc., can solve the problems of selectivity, sensitivity and moisture resistance, insufficient breath detection, etc., and achieve good selectivity, low cost, and low detection limit. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

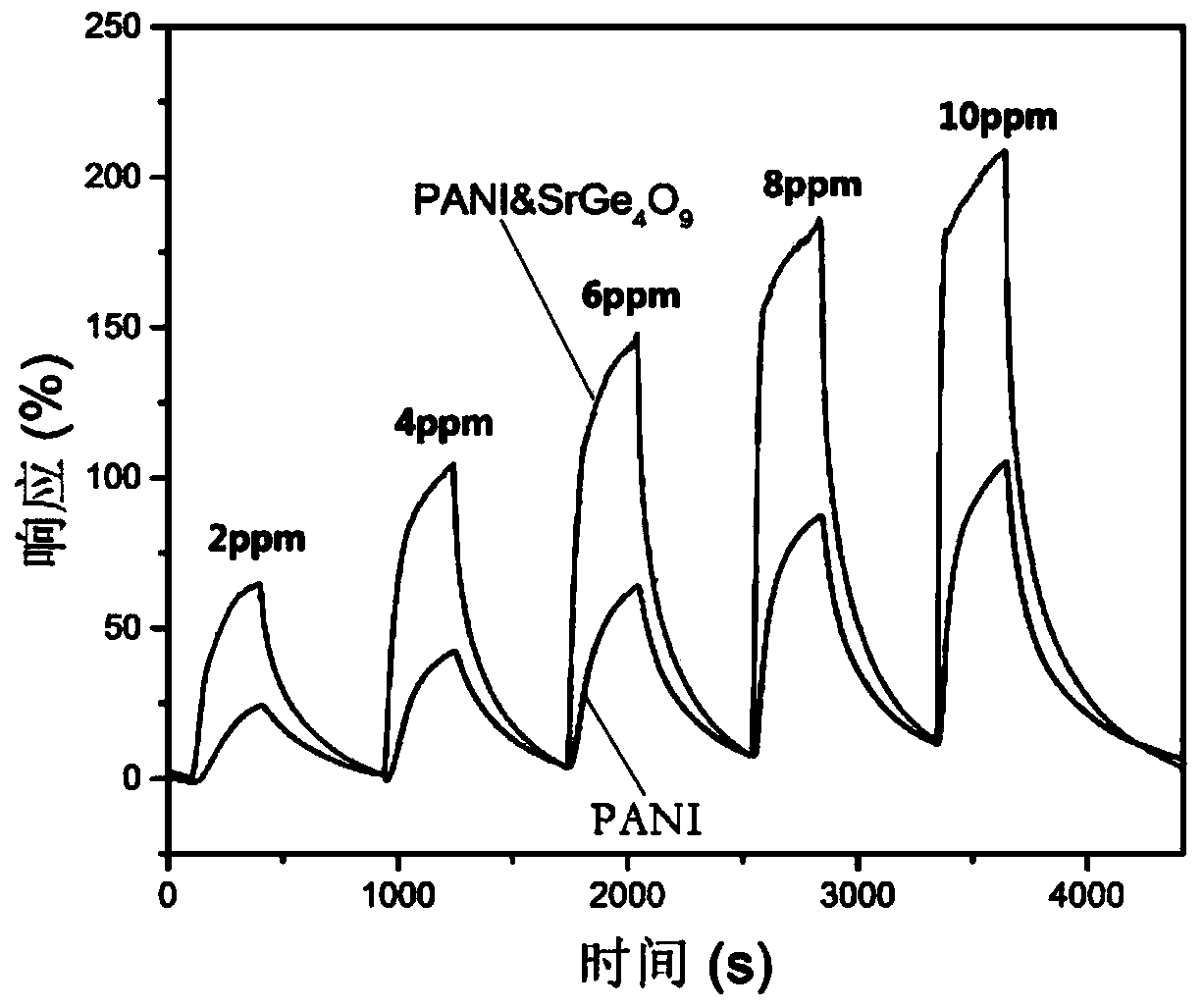

[0045] In the first embodiment of the present invention, a breath ammonia sensor based on polyaniline / semiconductor metal oxide nanocomposite film is provided.

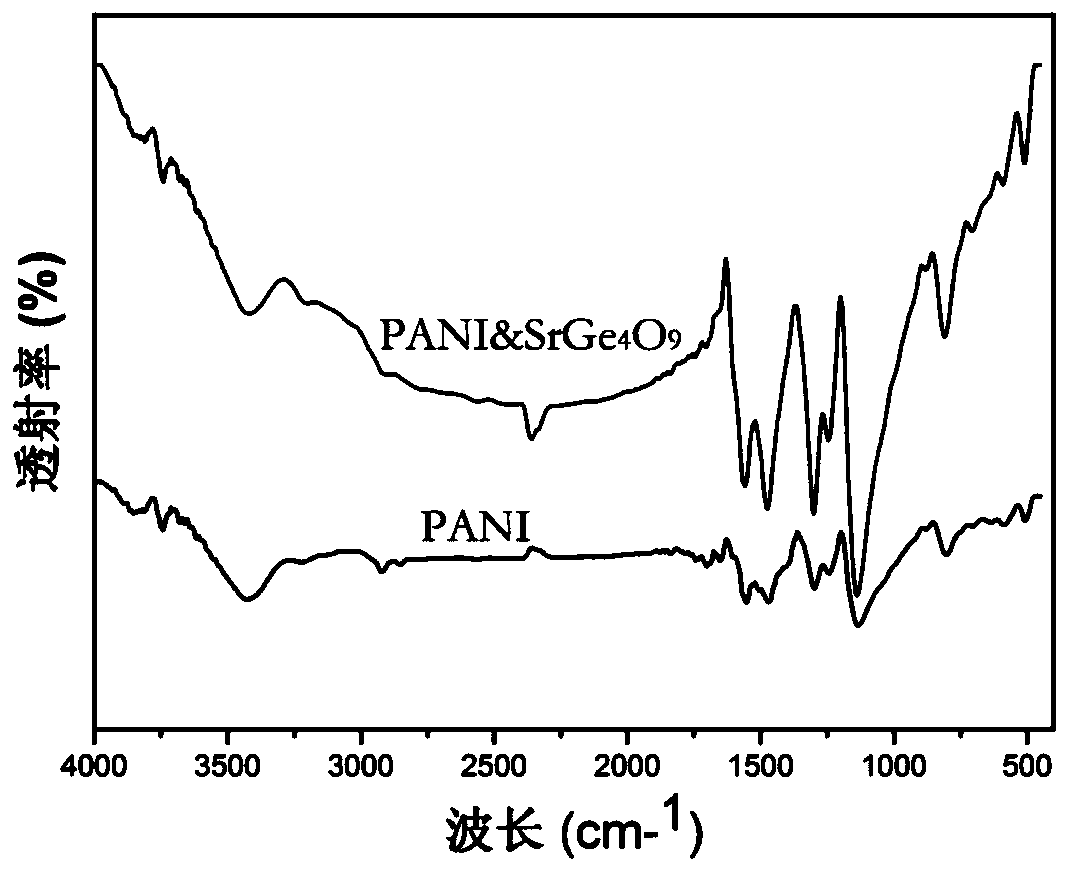

[0046] The breath ammonia sensor includes a polyaniline / metal germanate nanocomposite film, and the polyaniline / metal germanate nanocomposite film is a film formed by doping polyaniline with metal germanate, or the polyaniline / metal germanate The germanate nanocomposite film comprises a metal germanate film and a polyaniline film attached to the metal germanate film. in particular:

[0047] In a possible implementation manner, the polyaniline / metal germanate nanocomposite film has the same content of polyaniline and metal germanate components, and the two are evenly doped together. In another possible implementation, the polyaniline / metal germanate nanocomposite film is a layered film, including a metal germanate film and a polyaniline film attached to the metal germanate film, so The metal germanate film and the po...

no. 2 approach

[0055] In the second embodiment of the present invention, a method for preparing a breath ammonia sensor based on polyaniline / semiconductor metal oxide nanocomposite film is provided. in particular:

[0056] For the film formed by metal germanate doped polyaniline, the preparation method (A) comprises the following steps:

[0057] (1) cleaning the substrate, vapor-depositing the interdigitated electrodes to obtain the substrate device;

[0058] (2) Prepare metal germanate dispersion liquid, aniline monomer dispersion liquid, oxidant dispersion liquid;

[0059] (3) mixing the metal germanate dispersion liquid and the aniline monomer dispersion liquid uniformly, and introducing the oxidizing agent dispersion liquid for in-situ polymerization to obtain polyaniline / metal germanate nanocomposite materials;

[0060] (4) Depositing a thin film on the polyaniline / metal germanate nanocomposite material obtained in step (3) by using a film forming process.

[0061] Wherein, in step (...

Embodiment 1

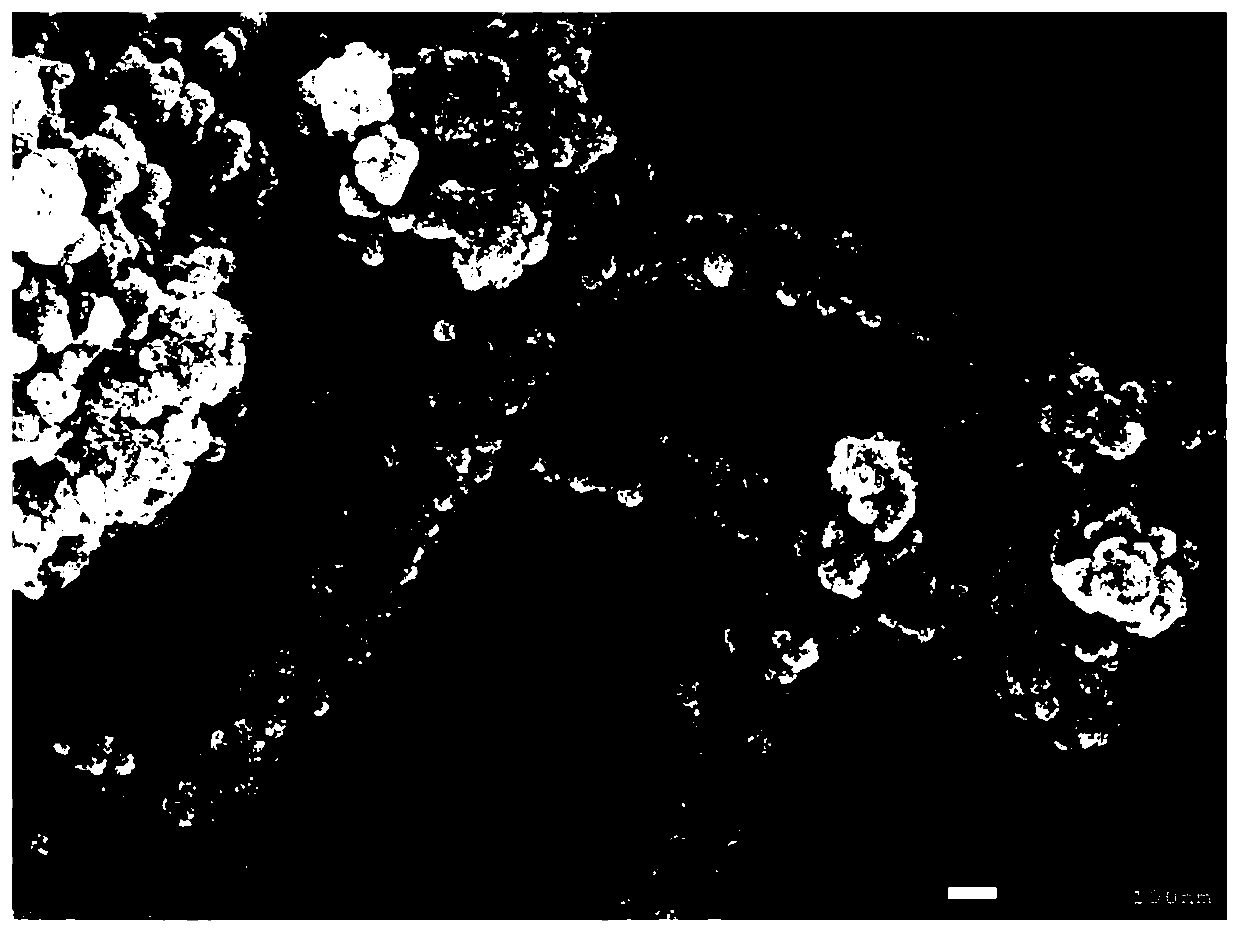

[0081] The substrate device selected in this embodiment is a flexible polyimide substrate, and gold interdigitated electrodes grown thereon; the interdigitated electrodes have an interdigital width of 180 μm, an interdigital spacing of 180 μm, and an electrode thickness of 120 nm. ; The germanate used in this embodiment is strontium germanate nanowires; the film-forming method used in this embodiment is a self-assembly method.

[0082] (1) Cut polyimide with a thickness of 100 μm into a size of 0.8*0.7cm; then wash the substrate in deionized water, acetone, deionized water, alcohol, and deionized water for 40 minutes, and then dry it in an oven; A gold interdigitated electrode with a thickness of 120 nm was evaporated on the polyimide substrate by using an evaporation apparatus.

[0083] (2) Soak the base device obtained in step (1) in PDDA (5 mg / mL) and PSS (0.1 wt%) solutions in deionized water for 15 min in sequence.

[0084] (3) Preparation of aniline monomer dispersion: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Interdigital gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com