A similar simulation test device with controllable loading and adjustable size

A technology similar to simulation and test devices, applied in soil material testing, material inspection products, etc., can solve the problems of fixed device model size, complex pouring model, and difficulty in popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

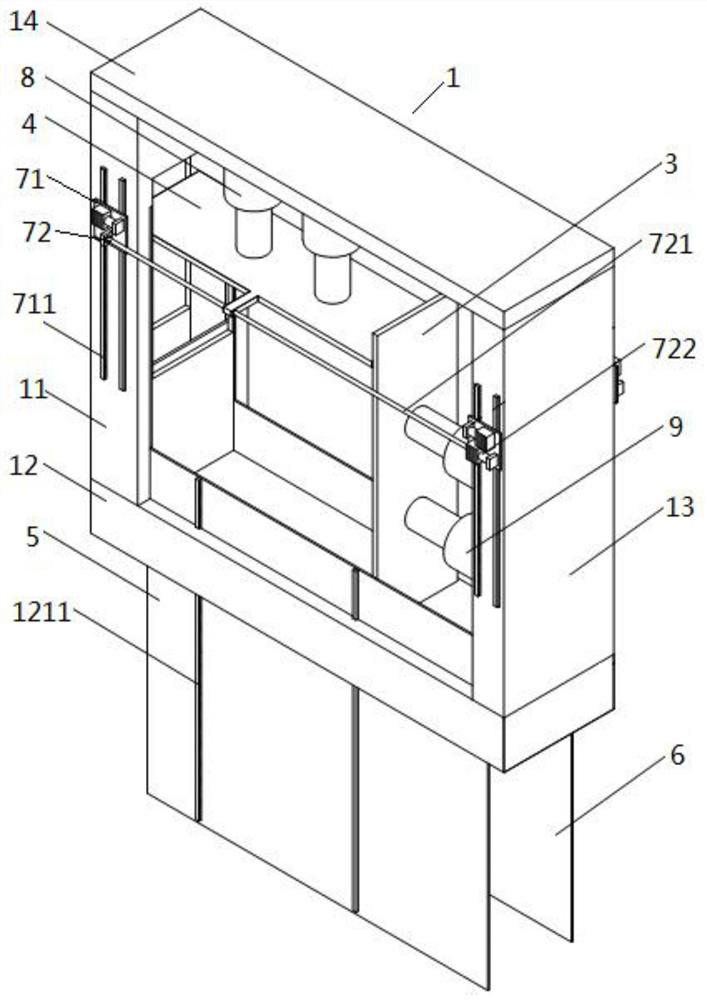

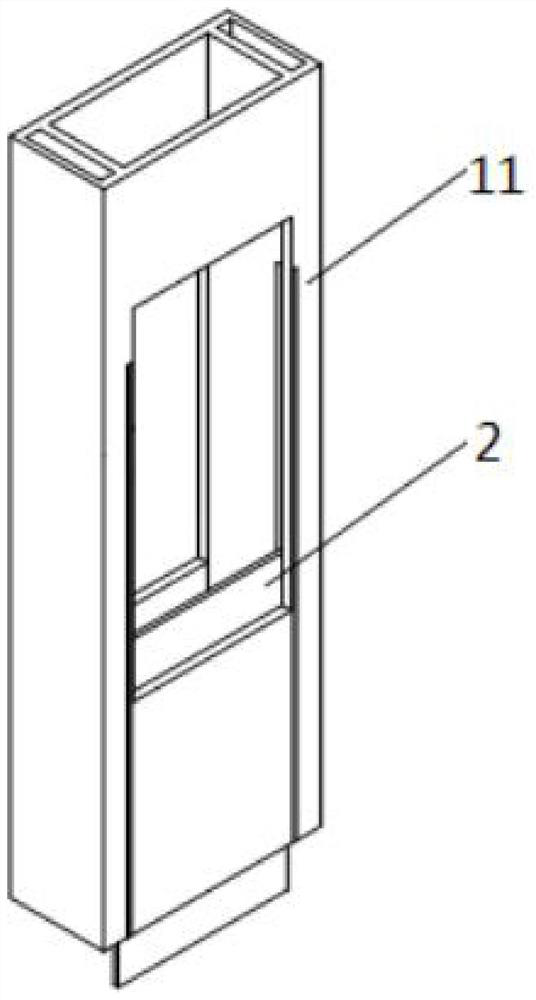

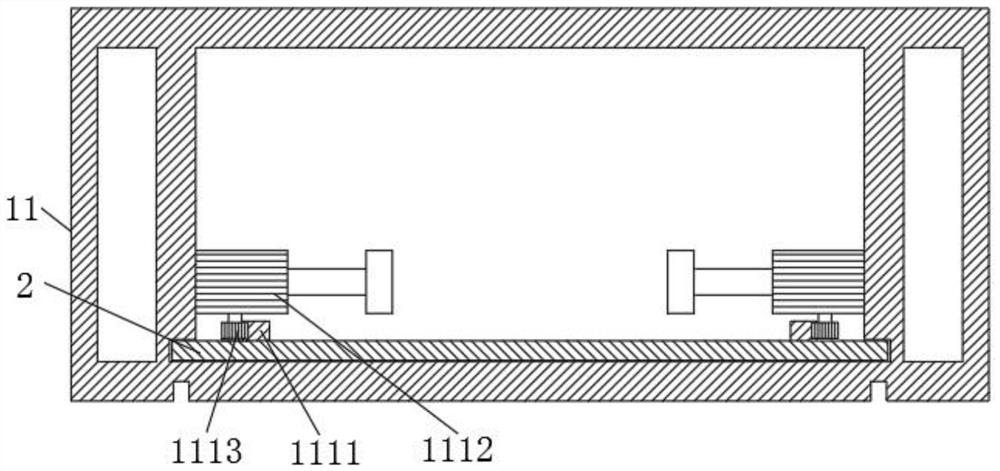

[0039] Example: such as figure 1 As shown, the similar simulation test device with controllable loading and adjustable size of the present embodiment includes a device frame 1, a left baffle 2, a right loading plate 3, an upper loading plate 4, a front baffle 5 and a rear baffle 6; The above-mentioned device frame 1 is a rectangular parallelepiped frame structure arranged vertically with open front and rear sides; the above-mentioned left baffle 2 is vertically arranged inside the left column 11 of the above-mentioned device frame 1 along the front-rear direction, and its lower end penetrates downward. The base 12 of the above-mentioned device frame 1 can slide up and down relative to the above-mentioned base 12; the above-mentioned right loading plate 3 is vertically arranged on the inside of the right column 13 of the above-mentioned device frame 1 along the front and rear direction, and the above-mentioned right column 13 is installed There is a horizontal loading device 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com