Gas turbine switch quantity feedback trouble shooting method

A switching value and fault technology, which is applied in the field of gas turbine switching value feedback troubleshooting, and can solve the problems of gas turbine down-state and shutdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

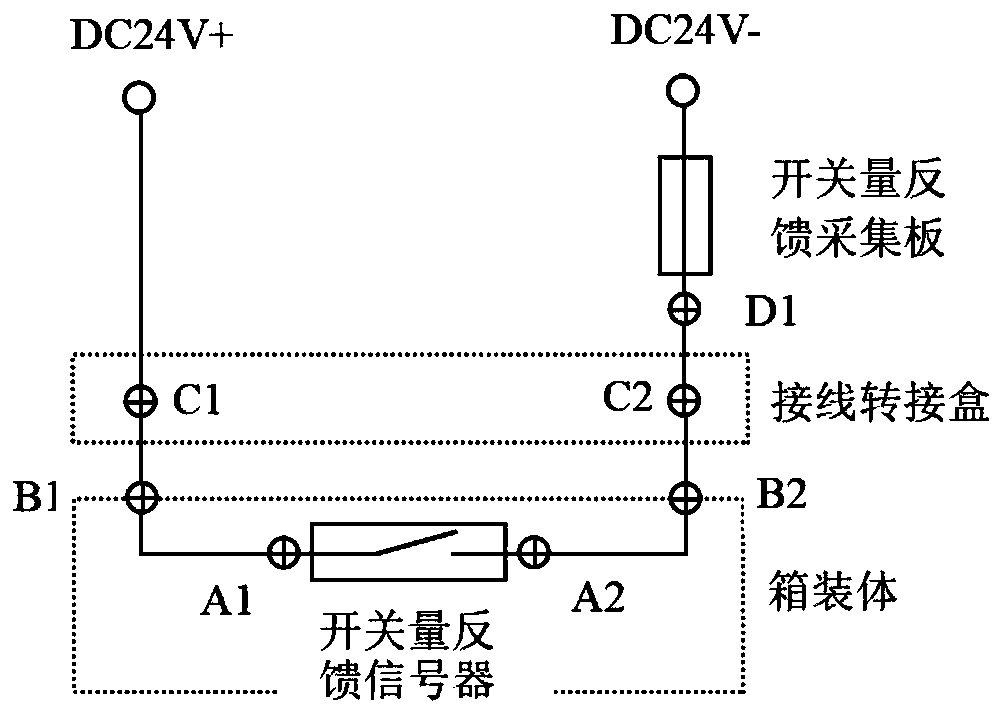

[0011] Such as figure 1 As shown, the present invention discloses a method for troubleshooting a gas turbine switching value feedback fault. When a certain switching value collected by the gas turbine control system is abnormal, the following troubleshooting should be performed:

[0012] Step 1: Check whether the ±24V DC voltage of the switch circuit power supply is normal. Use a multimeter to measure whether the circuit voltage is within the required range. If the measurement result is abnormal, check and replace the power supply.

[0013] Step 2: If the loop power supply is normal in step 1, unplug the signal plug connected to the switch feedback signal device, and short-circuit the signal plug A1 and A2 with a cable. The control system monitor panel shows that the switch feedback signal is 0 , The fault of the digital feedback annunciator can be eliminated at this time; if the control system monitoring panel shows that the digital feedback signal is 1, it can be judged that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com