Turbine blade detection method

A technology for turbine blades and detection methods, applied in image analysis, image enhancement, instruments, etc., can solve the problems of high processing difficulty, low processing yield, complex blade structure, etc., to improve production efficiency and quality, and save time and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

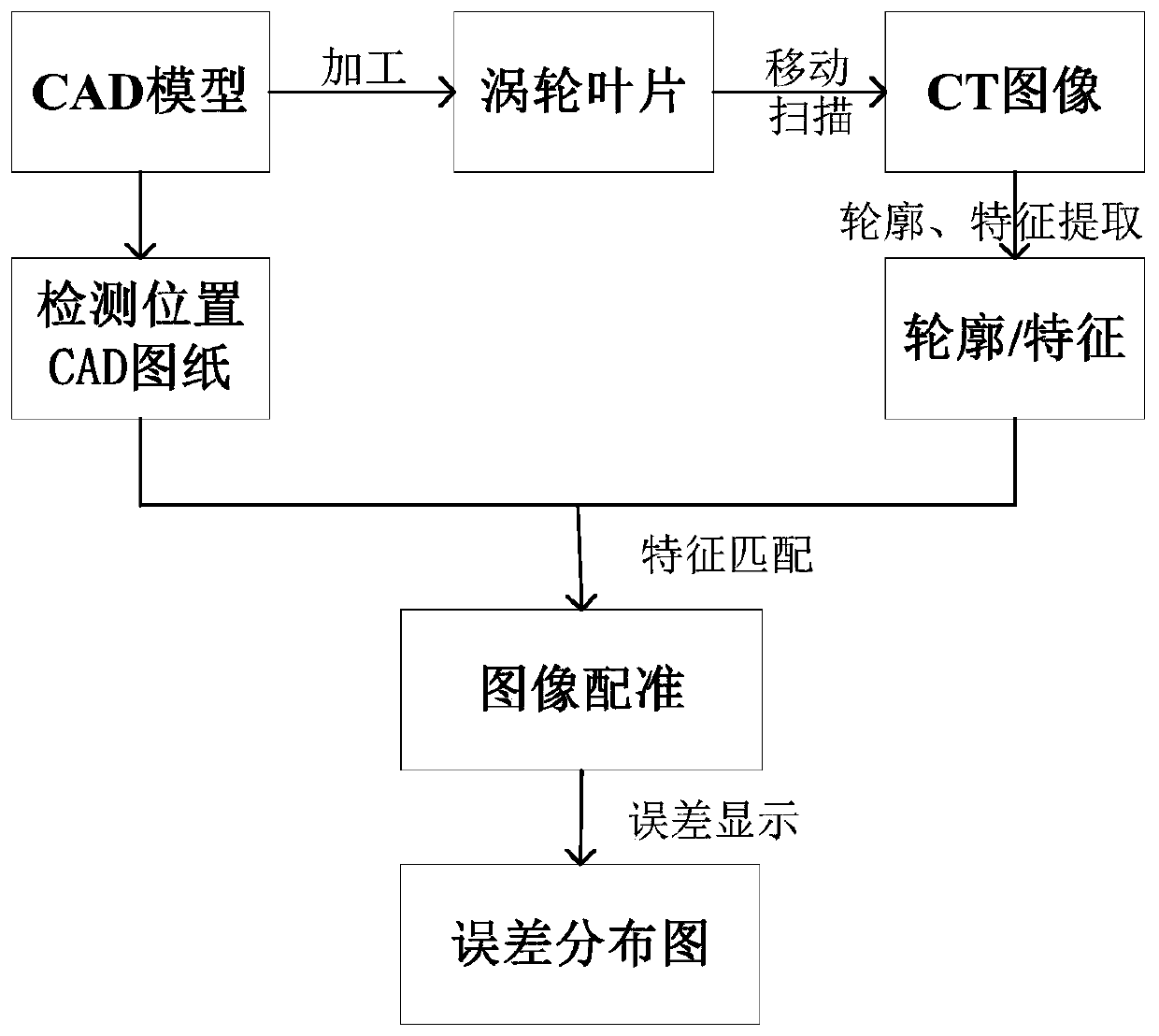

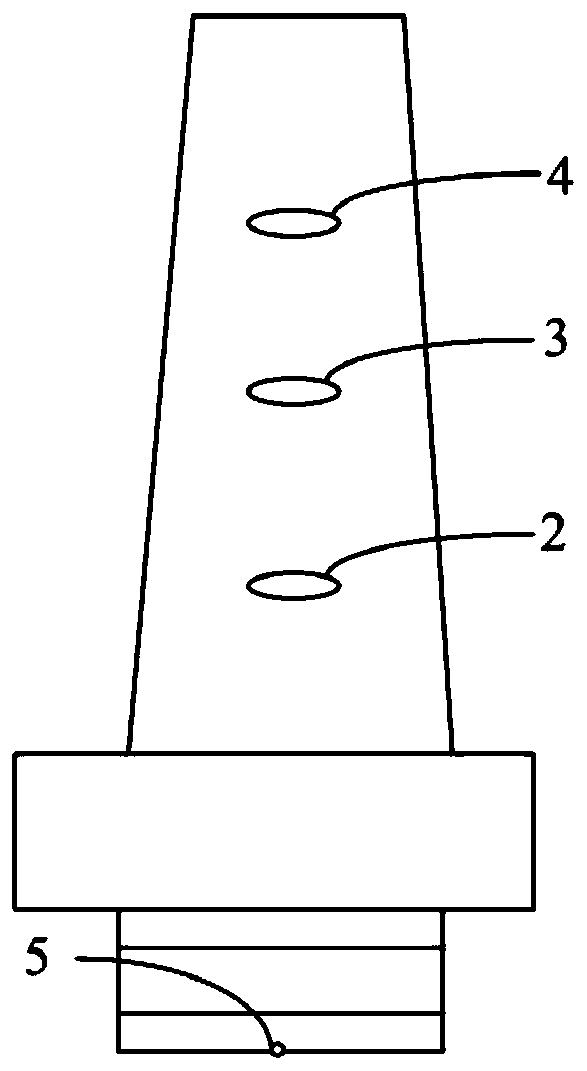

[0032] The detection method of the turbine blade in this example, such as figure 1 As shown, after the CAD model is designed, the turbine blade is directly processed according to the CAD model. The detection method of the present application is to perform CT scanning on the turbine blade to obtain a CT image before the turbine blade is further processed. At the same time, scan the CAD model The CAD image is obtained, and according to the contour and feature extraction of the CT image, the CAD image and the CT image are finely registered, and the error distribution map is obtained according to the registration result, so as to detect whether the turbine blade to be tested is qualified. details as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com