Weight-optimized steel piston

A technology for pistons and piston pin seats, which is applied in the direction of pistons, cylindrical pistons, plungers, etc., can solve the problems of unsatisfactory weight of pistons, and achieve the effects of weight reduction and simplified manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

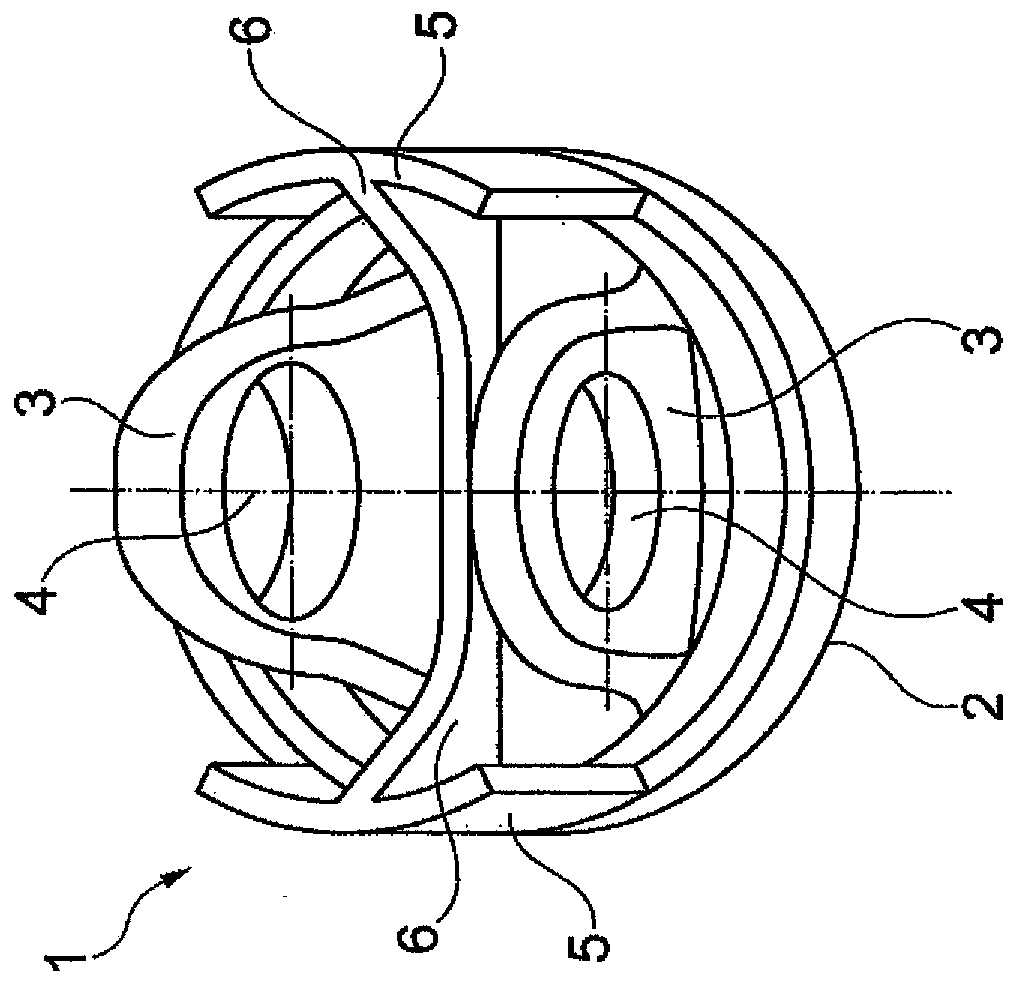

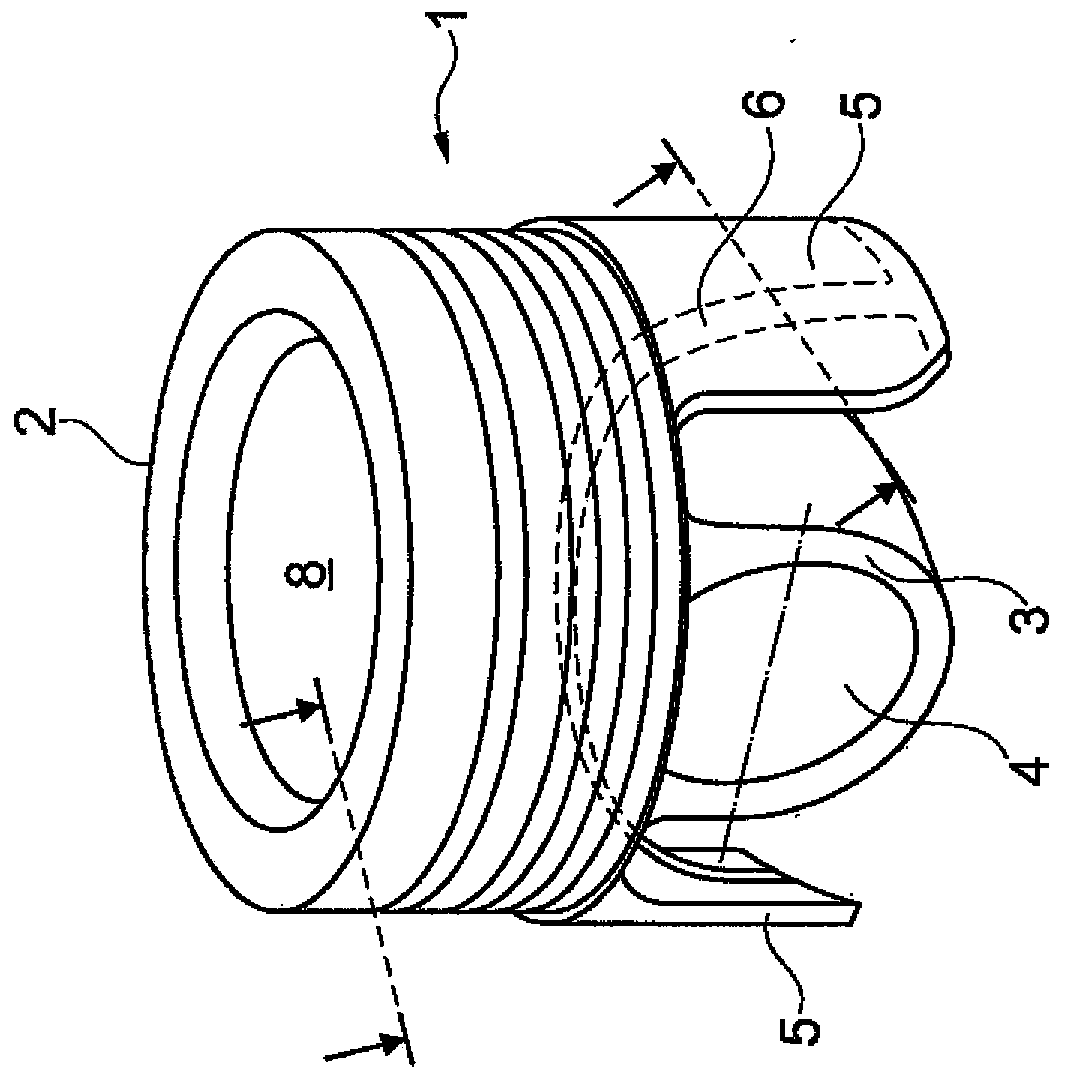

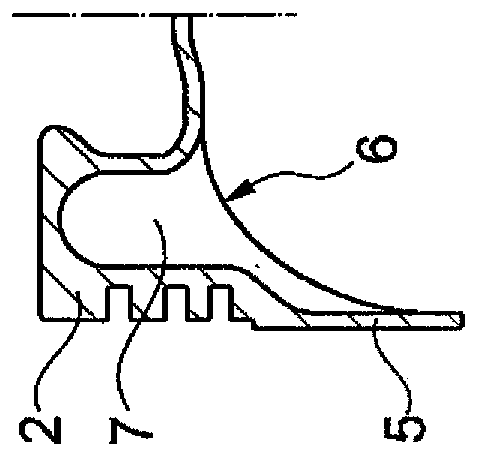

[0013] in Figure 1 to 4 A first embodiment of a piston 1 of an internal combustion engine is shown in FIG. The piston 1 has an upper part 2 which has: a piston pin seat 3 suspended thereon, in which there are pin holes 4 respectively; and a skirt wall section 5 that plays a bearing role. In this embodiment, the load-bearing skirt wall section 5 is unsupported on the upper part 2 on three sides, wherein the fourth side (one-piece or attached) is directly connected to the upper part 2 Part 2, especially connected to the underside of the upper part. The load-bearing skirt wall section 5 is supported by ribs 6 extending from the underside of the upper part 2 toward the load-bearing skirt wall section 5. The ribs 6 are formed symmetrically in the center and extend through the piston stroke axis.

[0014] in Figure 1 to 4 The piston 1 shown in may have (but does not necessarily have) a cooling channel 7 and a combustion chamber cavity 8. If a cooling channel 7 is present, it is clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com