power transmission control

A power transmission and control device technology, which is applied in transmission control, motor vehicles, transportation and packaging, etc., and can solve problems such as discomfort and collision sound for drivers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

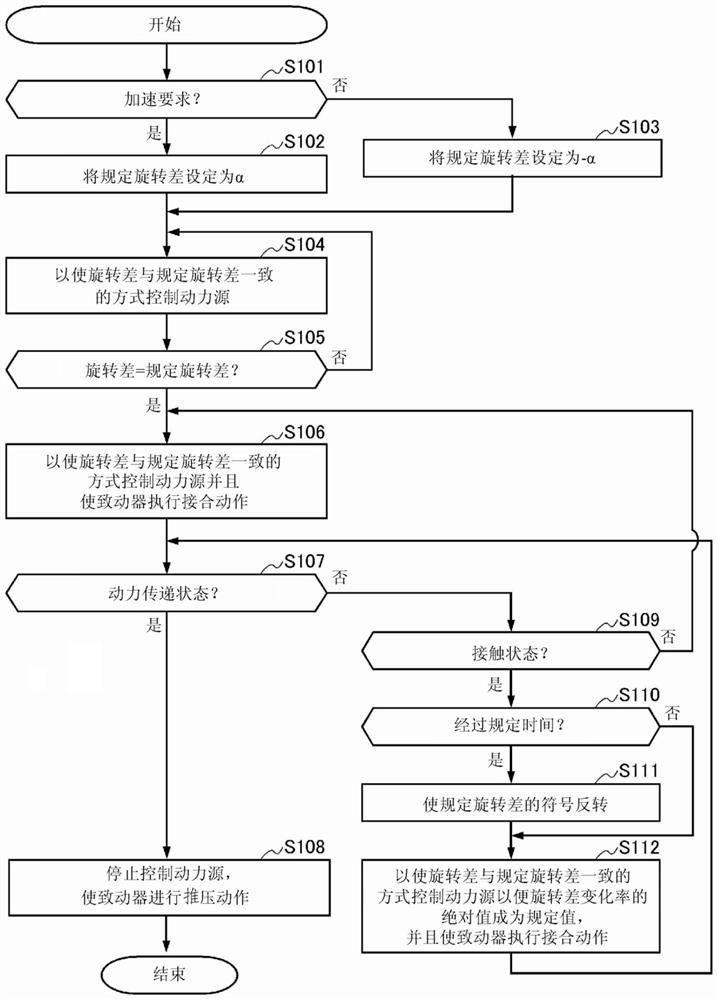

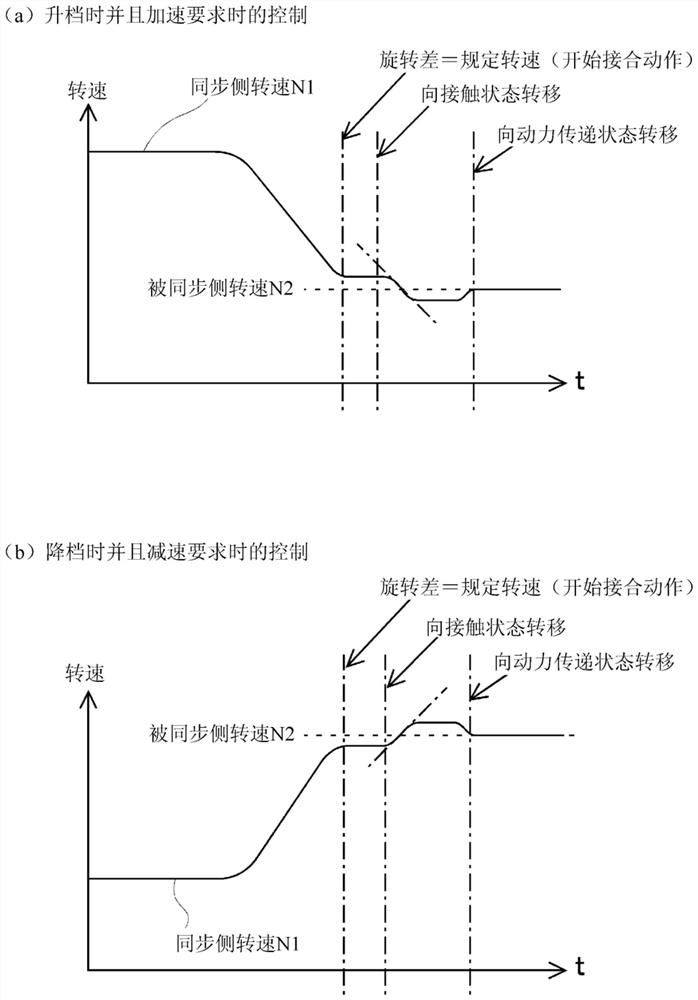

[0030] Hereinafter, an example of the power transmission control device 10 according to the first embodiment will be described with reference to the drawings. figure 1 It is an explanatory diagram showing the configuration of a vehicle related to the power transmission control device 10 of the present invention. exist figure 1 Among them, 11 is an engine as a power source, 12 is an input shaft as a first rotating shaft, 13 is a motor generator as another power source, 14 is a sleeve as a joint member, 15 is a fork, and 16 is a 17 is a shock absorber, 18 is an actuator, 19a and 19b are power transmission mechanisms, 20 is an output shaft as a second rotating shaft, and 21 is an engine control unit (hereinafter ECU) as a control part. To the input shaft 12 , an idler gear GA1 and an idler gear GB1 , which are engaged members, are connected so as to be relatively rotatable, and to the output shaft 20 , gears GA2 and GB2 are connected so as to be integrally rotatable. The firs...

no. 2 Embodiment approach

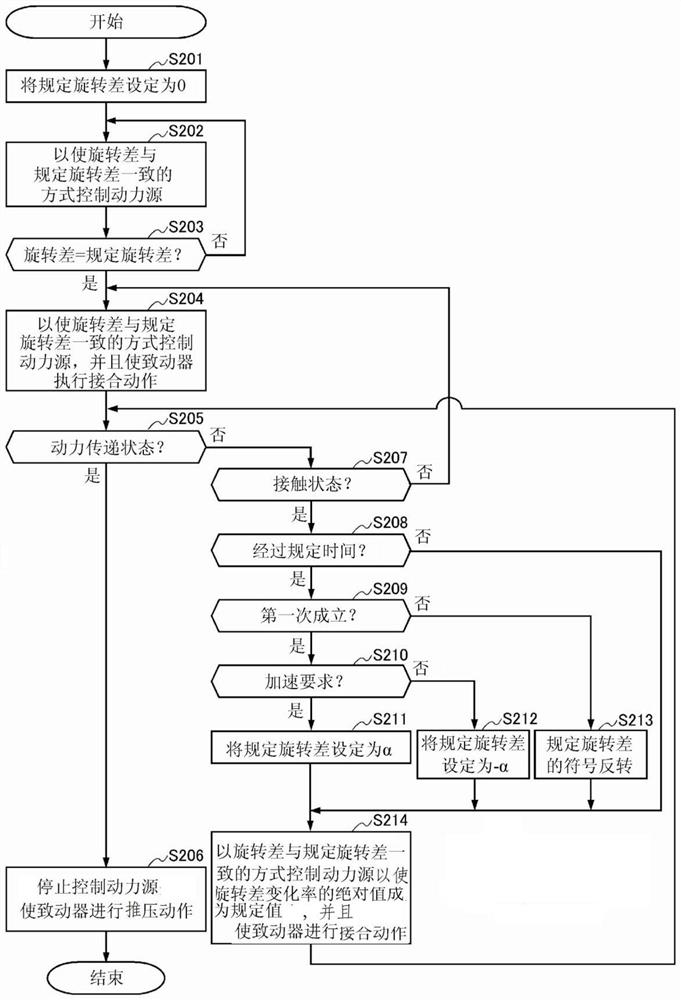

[0057] Next, an example of the power transmission control device 10 according to the second embodiment will be described with reference to the drawings. The configuration of the power transmission control device 10 according to the second embodiment and figure 1 are the same, so descriptions are omitted. This second embodiment is different from the first embodiment in that the synchronous-side rotational speed N1 and the synchronized-side rotational speed N2 are brought into agreement, and the transition to the contact state is started, and the synchronous-side rotational speed is controlled so that a rotation difference occurs after the contact state transition. N1.

[0058] Figure 4 It is a flowchart showing the flow of engagement operation control of the power transmission control device 10 according to the second embodiment of the present invention. The engagement operation control by the power transmission control device 10 according to the present invention starts f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com