An embedded permanent magnet array axial eddy current damper

An eddy current damper, permanent magnet array technology, applied in the direction of magnetic spring, spring/shock absorber, mechanical equipment, etc., can solve the problems of poor heat dissipation, inconvenient installation and disassembly, difficult installation and positioning, etc., and achieves reasonable structural design and convenience. The effect of installation and disassembly and improvement of heat dissipation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with appendix and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

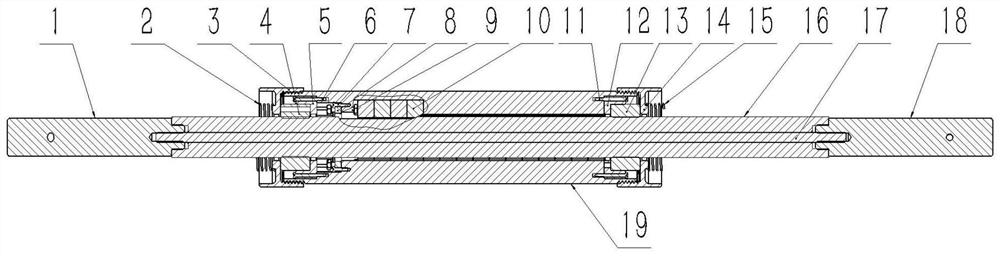

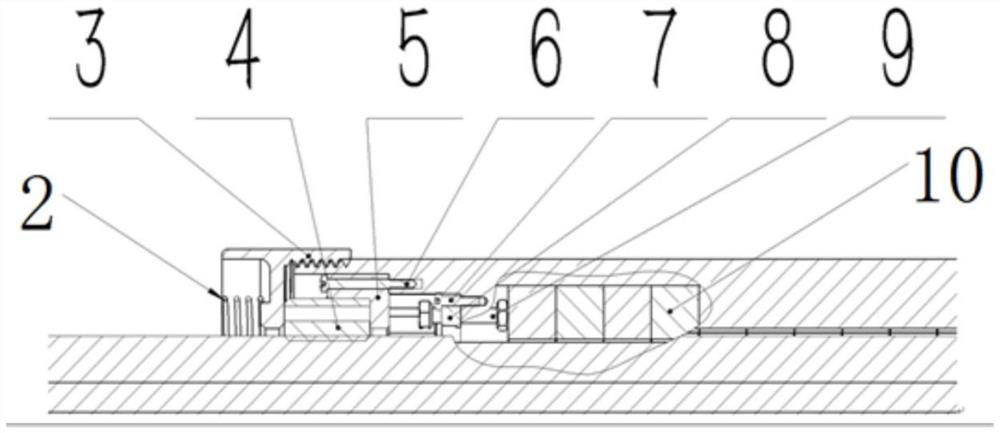

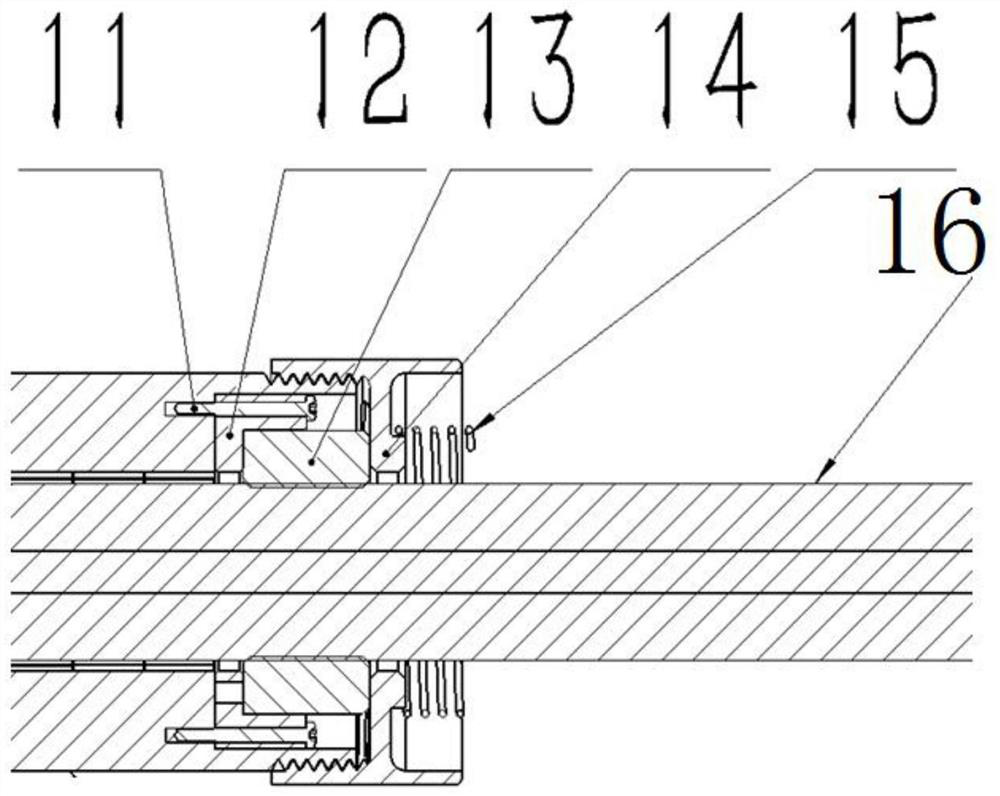

[0036] Such as Figure 1-3 As shown, an embedded permanent magnet array axial eddy current damper is characterized in that it includes a motion shaft assembly and a magnetic field source assembly, the motion shaft assembly is coaxially arranged with the magnetic field source assembly, and the motion shaft assembly includes The first end shaft 1, the second end shaft 18, the conductor cylinder 16 and the iron core 17, the conductor cylinder 16 is arranged through the magnetic field s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com