Automatic winding equipment for mobile phone camera coil

A mobile phone camera and automatic winding technology, which is applied in the direction of coil manufacturing, etc., can solve the problems of easy deviation of winding accuracy, high defective rate, difficulty in meeting the needs of mass production and rapid production and processing, and achieve good winding accuracy and Product quality, meet the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in detail below in conjunction with the accompanying drawings.

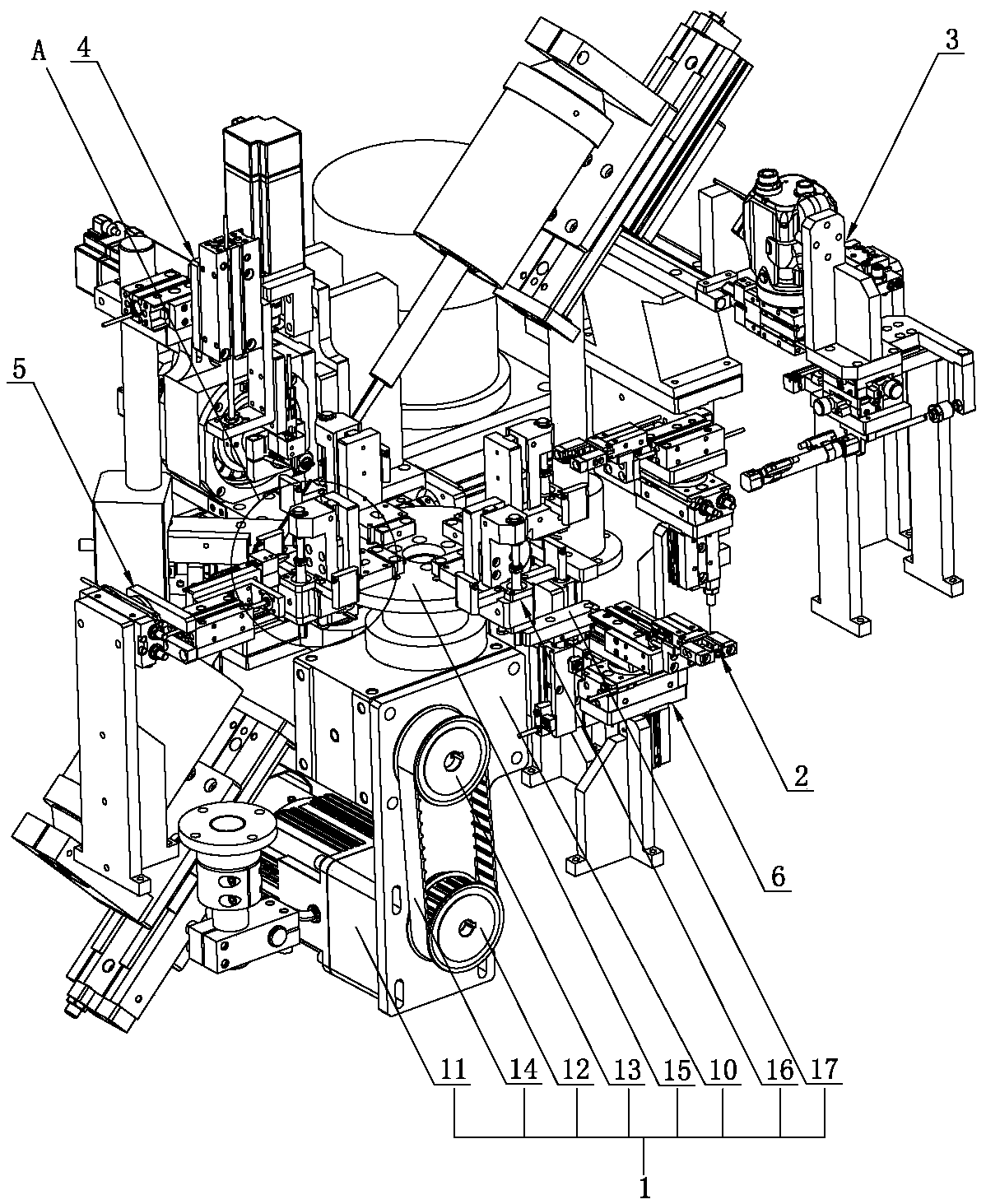

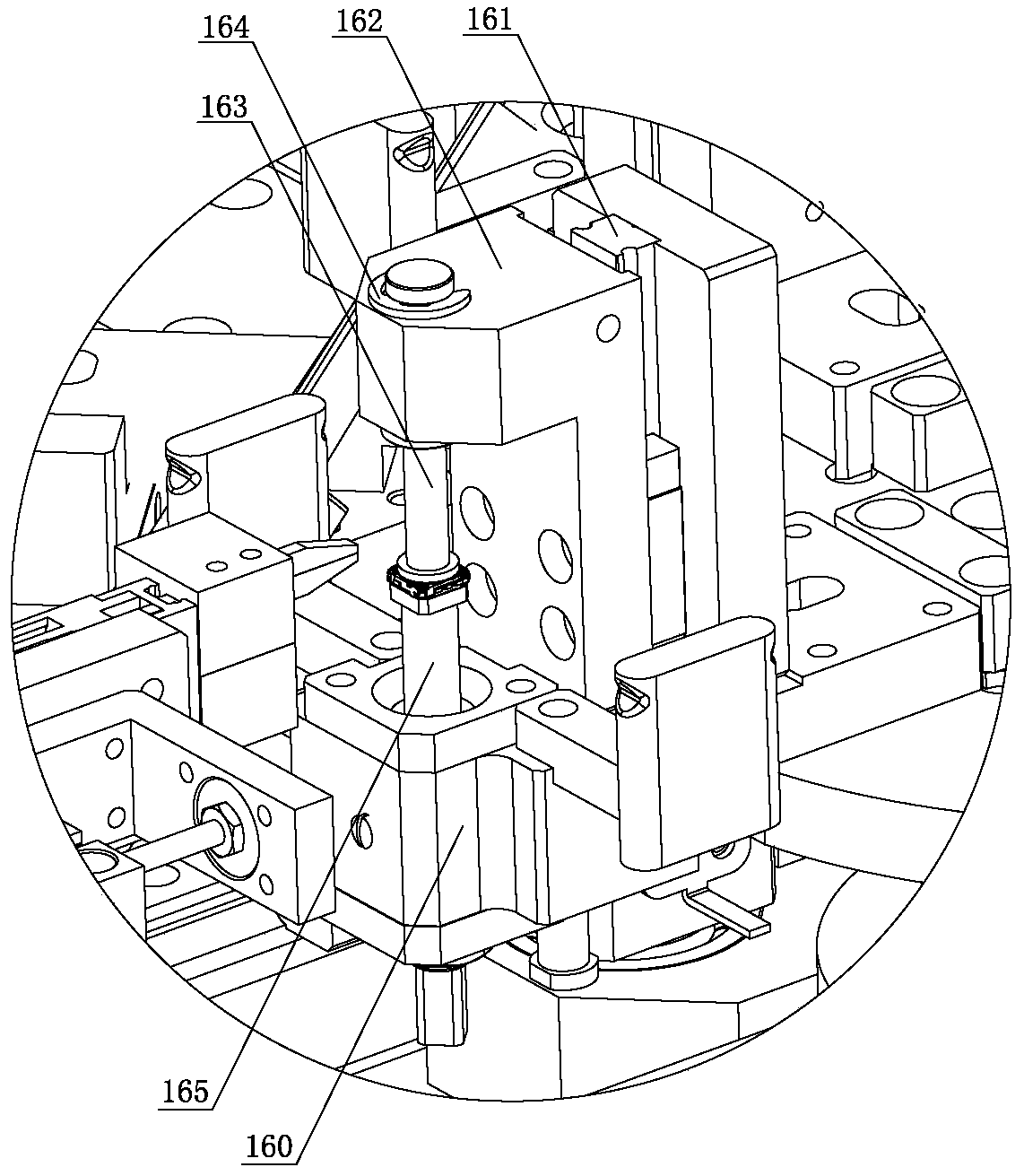

[0061] Such as Figure 1 to Figure 11 As shown, a mobile phone camera coil automatic winding device of the present invention includes a workbench 1, and the four sides of the workbench 1 are successively provided with a coil feeding mechanism 3 and a coil winding mechanism for processing the coil 2. 4. The thread pulling device 5 and the discharging device 6. The present invention realizes intelligent and automatic feeding, winding, pulling head and tail wires, and unloading operations on the coil 2, ensures good winding accuracy and product quality of the coil 2, and meets the processing requirements of mass production and rapid production.

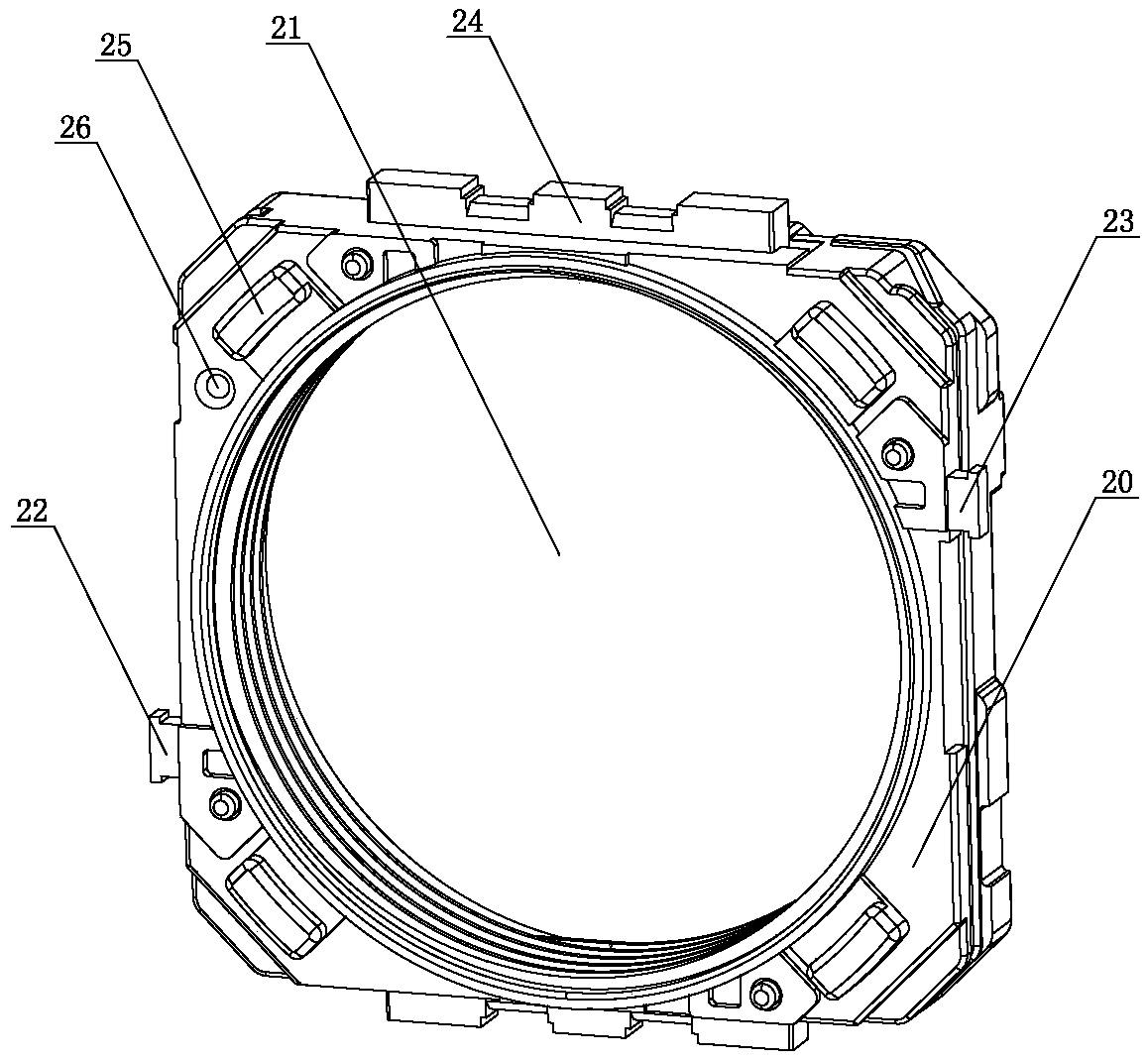

[0062] Such as figure 1 and image 3 As shown, the coil 2 of this embodiment includes a seat body 20, the middle part of which is provided with a through hole 21 for assembling the lens of the mobile phone camera, and the ou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap